Vacuum glass production process

A technology of vacuum glass and production process, which is applied in the field of building door and window glass production, which can solve the problems affecting the appearance and achieve the effect of improved aesthetics, high efficiency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

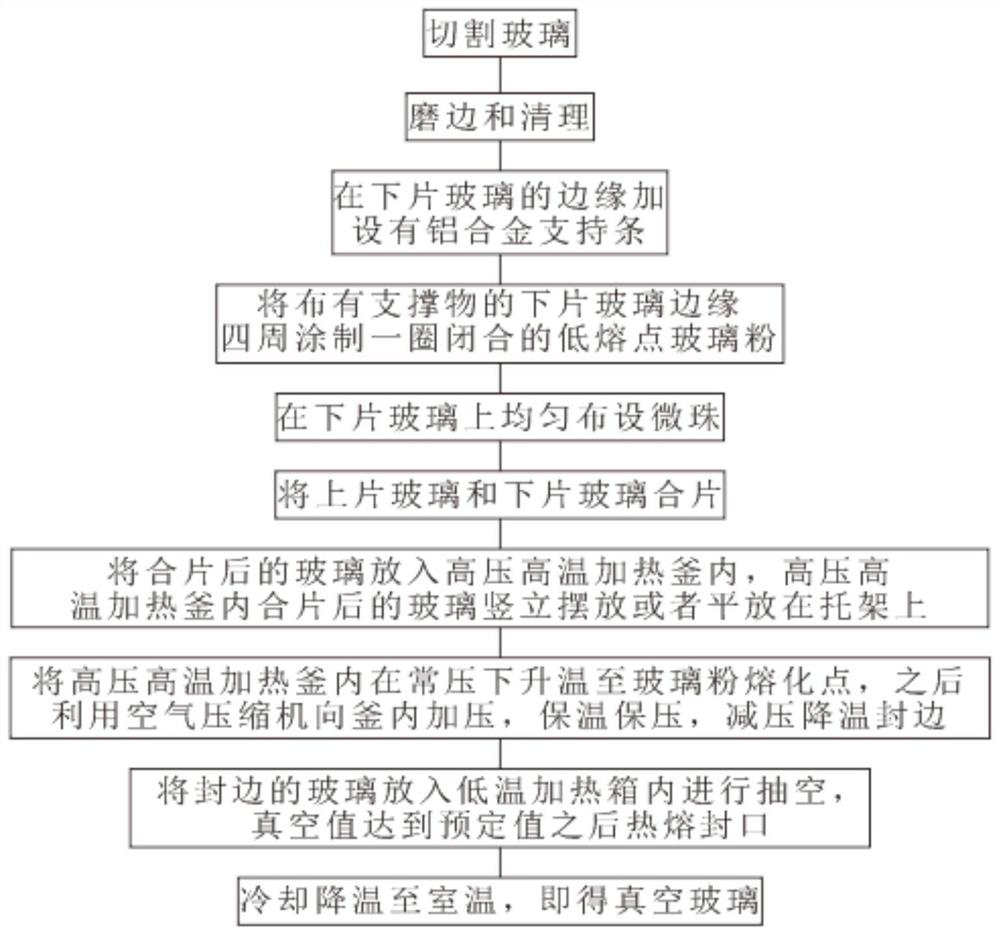

Image

Examples

Embodiment 1

[0022] A vacuum glass production process, characterized in that: comprising the following steps: step (1): cutting glass, intercepting upper glass and lower glass; step (2): edging and cleaning, and cleaning with deionized water after edging , and blow dry; step (3): add an aluminum alloy support strip on the edge of the lower glass; step (4): coat a circle of closed low-melting glass powder around the edge of the lower glass with the support ; Step (5): evenly distribute microbeads on the next sheet of glass again, and its layout method is to place a height of 5 millimeters and a diameter of 0.3 mm cylindrical microbead support on the following sheet of glass plate with an interval of 10 millimeters; step ( 6): Combine the upper glass and the lower glass; Step (7): Put the combined glass into a high-pressure and high-temperature heating kettle, and place the combined glass in the high-pressure and high-temperature heating kettle vertically or flatly On the bracket; step (8): ...

Embodiment 2

[0033] A vacuum glass production process, characterized in that: comprising the following steps: step (1): cutting glass, intercepting upper glass and lower glass; step (2): edging and cleaning, and cleaning with deionized water after edging , and blow dry; step (3): add an aluminum alloy support strip on the edge of the lower glass; step (4): coat a circle of closed low-melting glass powder around the edge of the lower glass with the support ; Step (5): evenly distribute the microbeads on the next sheet of glass again, and its layout method is to place a height of 20 millimeters and a diameter of 0.5 millimeters of cylindrical microbead supports on the next sheet of glass plate with an interval of 15 millimeters; step ( 6): Combine the upper glass and the lower glass; Step (7): Put the combined glass into a high-pressure and high-temperature heating kettle, and place the combined glass in the high-pressure and high-temperature heating kettle vertically or flatly On the bracke...

Embodiment 3

[0044] A vacuum glass production process, characterized in that: comprising the following steps: step (1): cutting glass, intercepting upper glass and lower glass; step (2): edging and cleaning, and cleaning with deionized water after edging , and blow dry; step (3): add an aluminum alloy support strip on the edge of the lower glass; step (4): coat a circle of closed low-melting glass powder around the edge of the lower glass with the support ; Step (5): evenly distribute microbeads on the next piece of glass again, and its layout mode is to place a height of 25 millimeters and a diameter of 1 millimeter cylindrical microbead support on the next piece of glass plate with an interval of 25 millimeters; step ( 6): Combine the upper glass and the lower glass; Step (7): Put the combined glass into a high-pressure and high-temperature heating kettle, and place the combined glass in the high-pressure and high-temperature heating kettle vertically or flatly On the bracket; step (8): ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com