Preparation method and application of super-hydrophobic MXene-based/cellulose composite aerogel

A composite airgel and superhydrophobic technology, which is applied in the field of preparation of superhydrophobic MXene-based/cellulose composite airgel, can solve the problems of cumbersome preparation methods and uneven material loading, and achieve good repeatability, The effect of uniform and comprehensive surface modification and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a superhydrophobic, superlipophilic MXene-based / cellulose composite airgel with photothermal properties, the method comprising the following steps:

[0052] (1) Weigh a certain mass of MAX powder (taking aluminum carbide titanium powder as an example) and dissolve it in a solution of hydrofluoric acid, wherein the mass of aluminum titanium carbide is 1g, and the volume of hydrofluoric acid is 20mL. ≥40%, and then inject nitrogen gas into the system for 30 minutes, and stir at 35°C for 12 hours after sealing with the parafilm, with a rotation speed of 300rpm. After the aluminum carbide titanium powder is etched, centrifuged, washed repeatedly with ultrapure water until the pH of the supernatant is around 6, then washed three times with absolute ethanol, freeze-dried to obtain MXene powder (taking titanium carbide powder as an example) ;

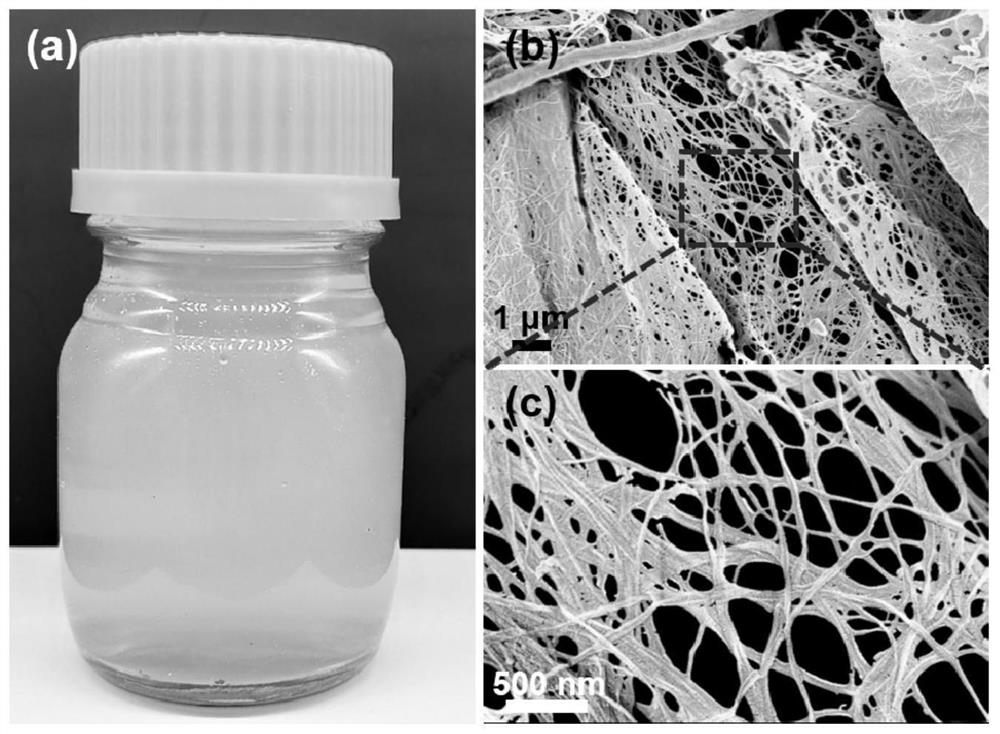

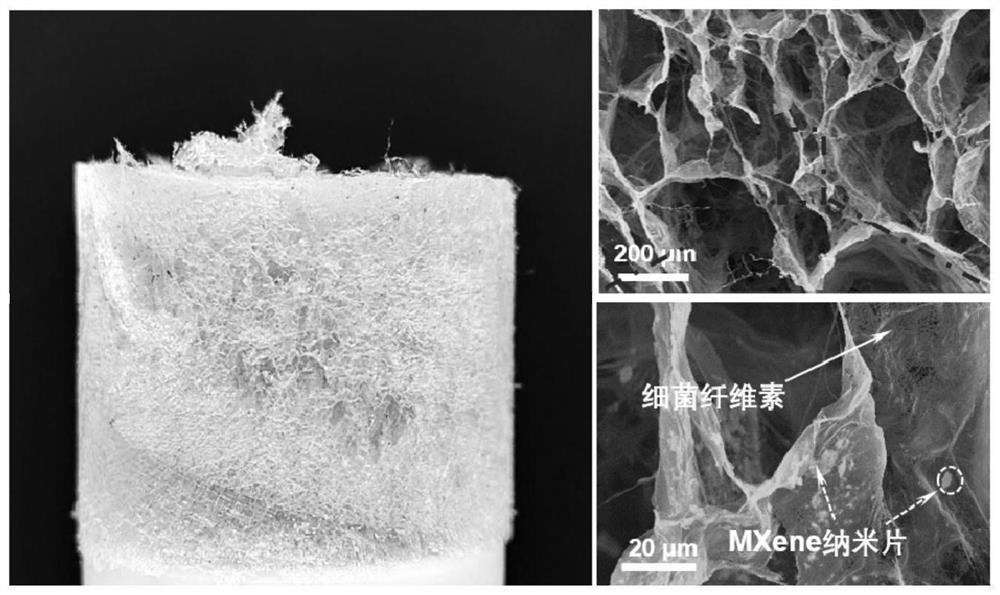

[0053] (2) Weigh a certain mass of titanium carbide powder and disperse it into ultrapure water, wherein the m...

Embodiment 2

[0057] A kind of superhydrophobic with photothermal performance, superlipophilic MXene base / cellulose composite airgel preparation method, the method comprises the following steps:

[0058] (1) Weigh a certain mass of MAX powder (taking aluminum carbide titanium powder as an example) and dissolve it in a solution of hydrofluoric acid, wherein the mass of aluminum titanium carbide is 10g, and the volume of hydrofluoric acid is 100mL. ≥40%, and then inject nitrogen gas into the system for 30 minutes, and stir at 35°C for 12 hours after sealing with the parafilm, with a rotation speed of 300rpm. After the aluminum carbide titanium powder is etched, centrifuged, washed repeatedly with ultrapure water until the pH of the supernatant is around 6, then washed three times with absolute ethanol, freeze-dried to obtain MXene powder (taking titanium carbide powder as an example) ;

[0059] (2) Weigh a certain mass of titanium carbide powder and disperse it into ultrapure water, wherein ...

Embodiment 3

[0063] A kind of superhydrophobic with photothermal performance, superlipophilic MXene base / cellulose composite airgel preparation method, the method comprises the following steps:

[0064] (1) Weigh a certain mass of MAX powder (taking aluminum carbide titanium powder as an example) and dissolve it in a solution of hydrofluoric acid, wherein the mass of aluminum titanium carbide is 1g, and the volume of hydrofluoric acid is 20mL. ≥40%, and then inject nitrogen gas into the system for 30 minutes, and stir at 35°C for 120 hours after sealing with the parafilm, with a rotation speed of 300 rpm. After the aluminum carbide titanium powder is etched, centrifuged, washed repeatedly with ultrapure water until the pH of the supernatant is around 6, then washed three times with absolute ethanol, freeze-dried to obtain MXene powder (taking titanium carbide powder as an example) ;

[0065] (2) Weigh a certain mass of titanium carbide powder and disperse it into ultrapure water, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com