Thermoplastic composite solid propellant and preparation method thereof

A solid propellant and thermoplastic technology, applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosive processing equipment, etc., can solve the problems of danger, poor low temperature resistance, etc., to reduce process costs and performance stability Good, fast vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method of thermoplastic composite solid propellant, comprising:

[0046] (1) The first method: heat the thermoplastic adhesive, add oxidant, plasticizer, metal fuel, sulfur, thiocarbamate and additives to the heated thermoplastic adhesive, and use the instant The mixer continues to heat and stir to form a uniform slurry, pour the above slurry, and let it stand for molding to obtain a low-melting point thermoplastic composite solid propellant; in the above steps, the heating temperature is 65-75°C; the stirring time is 40-150min ; When pouring, the slurry is poured into the mold or into the engine by vacuum spraying, and then rapidly self-crystallized at room temperature.

[0047] (2) The second method: use a vertical mixer to mix thermoplastic adhesives, oxidizers, plasticizers, metal fuels, sulfur, thiocarbamate and additives to obtain a uniform slurry and prepare it into a standard material The strips are transported to the screw extrusion molding devic...

Embodiment 1

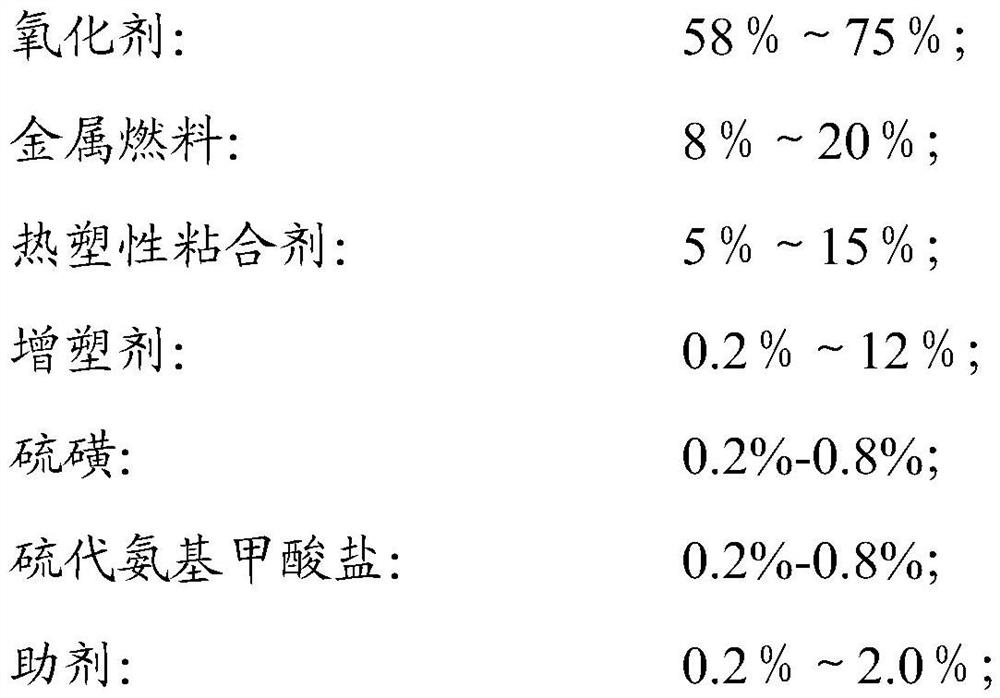

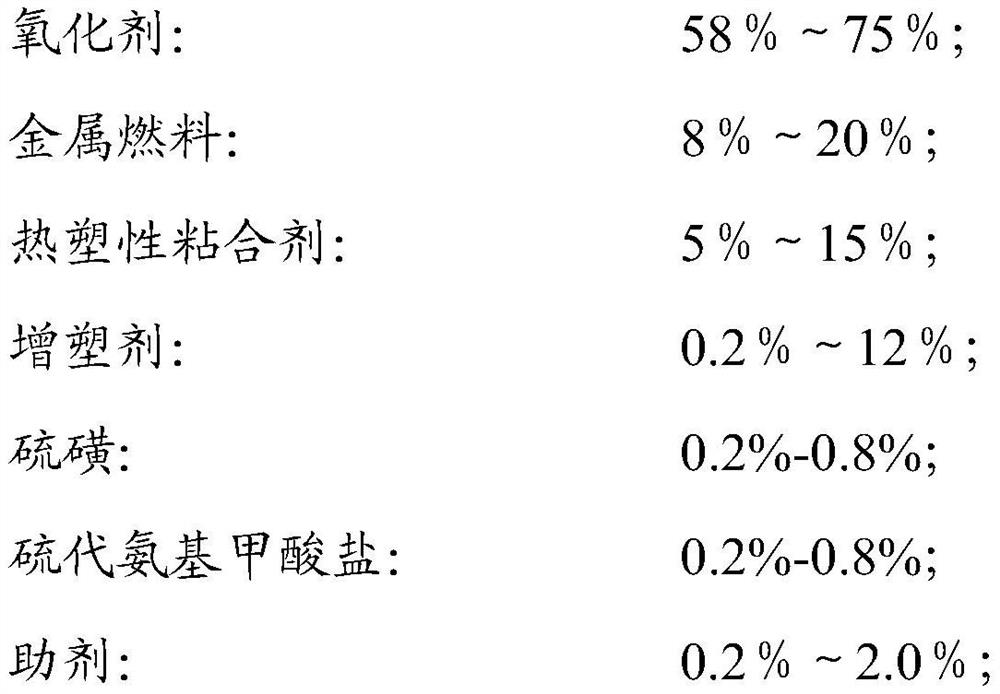

[0051] A thermoplastic composite solid propellant, based on the calculation of the total mass of the solid propellant as 100%, the mass percentage of each component is:

[0052] Oxidant (ammonium perchlorate): 70%;

[0053] Oxidant (Hexogen): 4%

[0054] Metal fuel (spherical aluminum powder): 13%;

[0055] Thermoplastic binder (trans-1,4-polyisoprene): 6%;

[0056] Plasticizer (high 1,2 polybutadiene): 6%;

[0057] Sulfur: 0.2%;

[0058] Thiocarbamate: 0.5%;

[0059] Auxiliary agent (lithium fluoride): 0.3%.

[0060] The thermoplastic adhesive is trans-1,4-polyisoprene, composed of two elements C and H, the glass transition temperature is -73°C, the melting point is in the range of 55-60°C, and the number average molecular weight is between 1000~2000;

[0061] The plasticizer is liquid high 1,2 polybutadiene, the content of 1,2 structure in high 1,2 polybutadiene is higher than 90%, and the number average molecular weight is between 1500 and 2000;

[0062] The prepara...

Embodiment 2

[0072] A thermoplastic composite solid propellant, based on the calculation of the total mass of the solid propellant as 100%, the mass percentage of each component is:

[0073] Oxidant (ammonium perchlorate): 60%;

[0074] Metal fuel (spherical aluminum powder): 13%;

[0075] Metal fuel (spherical aluminum-magnesium alloy powder): 4%;

[0076] Thermoplastic binder (mixture of trans-1,4-polyisoprene and acetylene black): 10.5%;

[0077] Plasticizer (high 1,2 polybutadiene): 11%;

[0078] Sulfur: 0.2%;

[0079] Thiocarbamate: 0.3%;

[0080] Additives: 1.0%.

[0081] The thermoplastic adhesive is trans-1,4-polyisoprene, composed of two elements C and H, the glass transition temperature is -73°C, the melting point is in the range of 55-60°C, and the number average molecular weight is between 2500~4000;

[0082] The plasticizer is liquid high 1,2 polybutadiene, the content of 1,2 structure in high 1,2 polybutadiene is higher than 90%, and the number average molecular weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com