Lateral double diffused field effect transistor, manufacturing method, chip and circuit

A technology of field effect transistors and lateral double diffusion, which is applied in the direction of circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of driving ability and speed difference, and achieve increased speed, improved carrier mobility, and weakened band The effect of scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

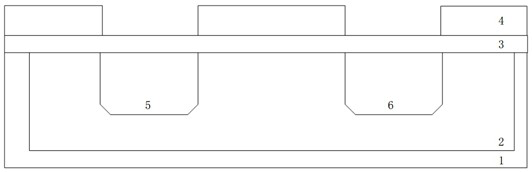

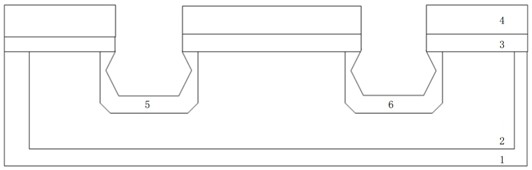

[0031] The specific implementation of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that this

[0034] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

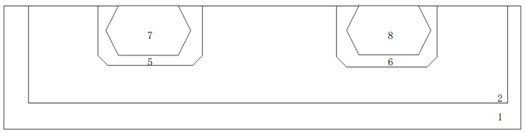

[0038] A first drain 10 is formed in the first tensile strain region 7, a second drain 11 is formed in the second tensile strain region 8, and a P-type body is formed.

[0039] Through the lateral double diffusion field effect transistor of the embodiment of the present invention, a strained material is embedded in the drift region to form

[0040] Further, the first tensile strain region 7 and the second tensile strain region 8 are hexagonal structures.

[0042] Further, the first tensile strain region 7 and the second tensile strain region 8 include silicon carbide.

[0044] Further, the first tensile strain region 7 and the second tensile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com