Silicon nitride ceramic piston rod and preparation method thereof

A silicon nitride ceramic and piston rod technology, applied in pistons, mechanical equipment, epoxy resin glue, etc., can solve the problems of large difference in thermal expansion coefficient of piston rod, ceramic layer falling off, limiting the thickness of ceramic layer, etc., to ensure sustainable Effects of Sex and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

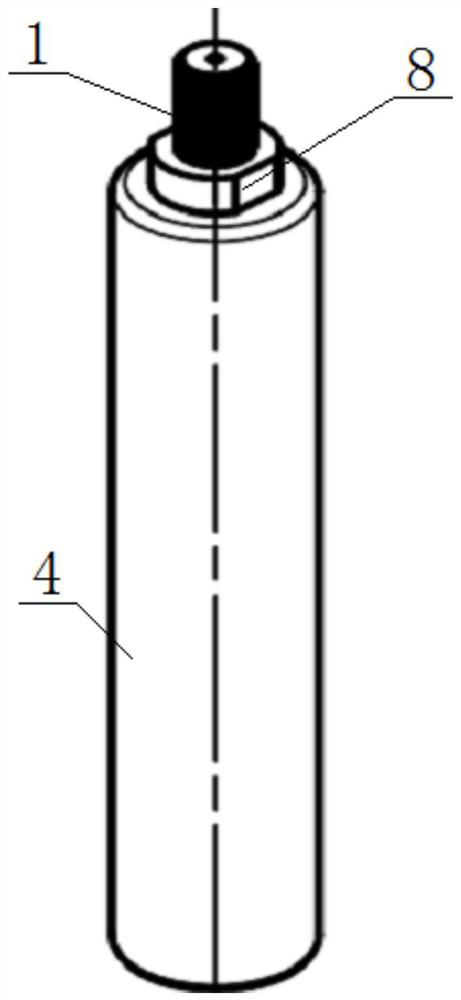

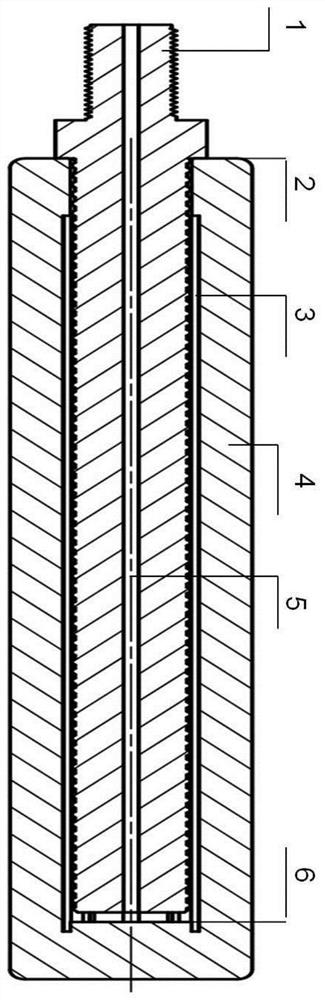

[0045] A silicon nitride ceramic piston rod, comprising:

[0046] A mandrel 1, the mandrel 1 is provided with a thread 6;

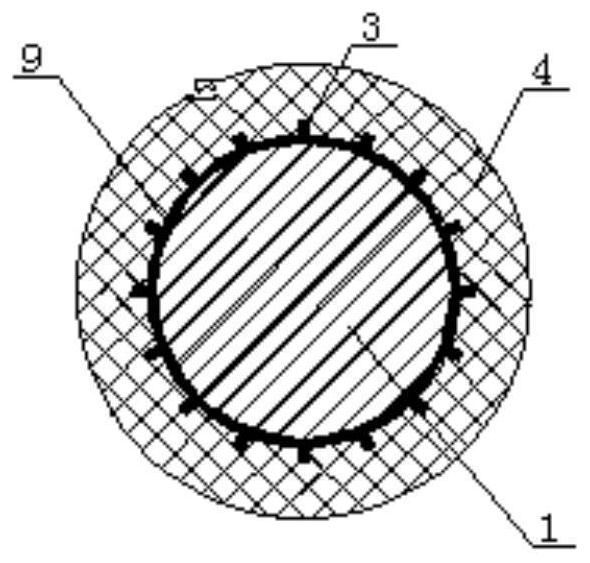

[0047] The ceramic bushing 4 is sheathed on the outside of the mandrel 1, and the mandrel 1 and the ceramic bushing 4 are connected through an adhesive layer 9; the mandrel 1 is relatively located outside the ceramic bushing 4 with a limit seat 8. There is an end gap 2 between the limit seat 8 and the ceramic bushing 4 .

[0048] The adhesive layer 9 includes the following raw materials in parts by weight: 80-100 parts of epoxy resin, 20-40 parts of amine curing agent, 5-10 parts of quartz ceramic powder or boron nitride ceramic powder, short 3 to 5 servings of fiber.

[0049] Such as figure 1 As shown, it also includes a first glue storage tank 3 located on the inner wall of the ceramic bushing 4, and the adhesive layer 9 is filled in the first glue storage tank 3 and between the mandrel 1 and the ceramic bushing 4; as Optionally, the ceramic bushing...

Embodiment 2

[0058] This embodiment provides a method for preparing a silicon nitride ceramic piston rod,

[0059] Step 1: Preparation of ceramic bushing: After sintering, the high-purity dense silicon nitride ceramic blank (purity ≥ 88%) is mechanically cold-processed to form a length of 450 mm, an outer diameter of 80 mm, an inner diameter of 40 mm, and a bottom thickness of 20mm cylindrical socket.

[0060] Step 2: Preparation of the mandrel: select 310S heat-resistant stainless steel bar, and through mechanical processing, prepare a cylindrical mandrel with a length of 500mm and an outer diameter of 39mm, and set an overflow glue with an inner diameter of 5mm and run through the mandrel Holes, milling coarse threads on the mandrel section of the bonding assembly with the ceramic bushing to increase the bonding area.

[0061] Step 3: Bonding of the ceramic bushing to the mandrel:

[0062] ① Cleaning of ceramic bushings.

[0063] Use anhydrous ethanol to clean the inner and outer wall...

Embodiment 3

[0075] This embodiment provides a method for preparing a silicon nitride ceramic piston rod,

[0076] Step 1: Processing and preparation of ceramic bushings: After sintering, the high-purity dense silicon nitride ceramic blank (purity ≥ 88%) is mechanically cold-processed to form a length of 450mm, an outer diameter of 80mm, an inner diameter of 40mm, and a thickness of the bottom It is a 20mm cylindrical sleeve, and grooves with a width of (2-5) mm are evenly processed on the inner wall of the ceramic bushing, and the groove spacing is (10-20) mm.

[0077] Step 2: Processing and preparation of the mandrel: select 310S heat-resistant stainless steel bar, and through mechanical processing, prepare a cylindrical mandrel with a length of 500 mm and an outer diameter of 39 mm. The glue hole is milled with coarse threads on the mandrel section of the bonding assembly with the ceramic bushing to increase the bonding area.

[0078] Step 3: Adhesive assembly of ceramic bushing and ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com