Preparation method of fluoroplastic heat exchange structure

A technology of heat exchange structure and fluoroplastics, which is applied in the direction of tubular objects, household appliances, and other household appliances, and can solve the problem that the high thermal conductivity of carbon fiber and the convective heat transfer capacity of carbon fiber do not match the axial thermal conductivity, which is not sufficient. and other problems, to achieve high axial strength and modulus, improve mechanical properties, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

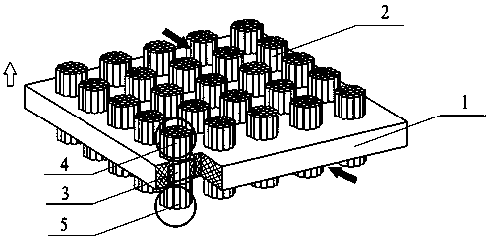

[0041] A preparation method of a fluoroplastic heat exchange structure is characterized in that it comprises the following steps:

[0042] (1) Firstly, the commercially available high thermal conductivity carbon fiber tow is selected as the raw material, and the tow is a continuous filament. The axial thermal conductivity λ of the carbon fiber monofilament and the diameter of the carbon fiber monofilament are measured by experiments. d , tow diameter D value;

[0043] (2) According to the application needs and considering the risk of seal leakage, comprehensively determine the design thickness of the fluoroplastic heat exchange structure matrix t ;

[0044] (3) The high thermal conductivity carbon fiber tow must reach a certain distribution density on the surface of the fluoroplastic substrate r , r Expressed by the percentage of the sum of its radial cross-sectional area and the average area of the upper and lower surfaces of the fluoroplastic matrix, according to the d...

Embodiment 1

[0058] Embodiment 1: choose the Thornel K1100 high thermal conductivity carbon fiber tow of U.S. Amoco Company as raw material, its axial thermal conductivity is 950 W / (m * K), monofilament diameter 6.9 micron, tow diameter 0.56 millimeter; Vinyl fluoride is used as the matrix material, and its design thickness is 0.5 mm; after calculation and judgment, the distribution density of high thermal conductivity carbon fiber tow should be 1%, that is, 4 bundles of carbon fiber tow are evenly distributed on each square centimeter.

[0059] The upper surface of the heat exchange structure is a high-temperature fluid channel, and water is selected as the high-temperature fluid at a temperature of 45 degrees Celsius; under the design condition, the surface convective heat transfer coefficient between the high-temperature fluid and the carbon fiber tow is 2000 W / (m×K), according to According to the calculation of the matching relationship, the length of the upper ciliated rib should be gr...

Embodiment 2

[0072] Embodiment 2: choose the Torayca M40J high thermal conductivity carbon fiber tow of Toray Corporation of Japan as raw material, its axial thermal conductivity is 67 W / (m * K), 7.0 micron of monofilament diameter, 0.88 millimeter of tow diameter; Tetrafluoroethylene is the matrix material, and its design thickness is 0.5 mm; after calculation and judgment, the distribution density of high thermal conductivity carbon fiber tow should be 4.5%, that is, 7.5 bundles of carbon fiber tow are evenly distributed on each square centimeter area.

[0073] The upper surface of the heat exchange structure is a high-temperature fluid channel, and water is selected as the high-temperature fluid at a temperature of 45 degrees Celsius; under the design condition, the surface convective heat transfer coefficient between the high-temperature fluid and the carbon fiber tow is 2000 W / (m×K), according to According to the calculation of the matching relationship, the length of the upper ciliate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com