Fuel oil tank with external circulation filtering device and fuel oil engine

A technology of external circulation and filtering devices, which is applied in the direction of engine components, machines/engines, liquid fuel feeders, etc., can solve the problems of high equipment failure rate, low operating efficiency, and shortened life, and achieve high filtration accuracy and reduce power Consumption of cost, the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

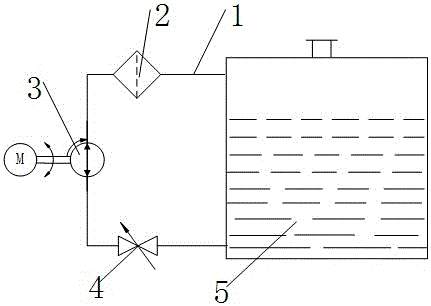

[0035] like figure 1As shown, a fuel tank with an external circulation filter device includes a fuel tank 5 and a filter device arranged outside the fuel tank. The fuel tank can be an oil storage tank or an engine fuel tank. The filter device includes a hydraulic pump 3, a filter 2, and an oil intake and oil return pipeline 1, and the oil intake and oil return pipeline 1 is arranged on the housing of the fuel tank 5; Inhaled, filtered by the filter filter 2 and then discharged to the fuel tank 5 through the oil return line. A check valve 4 is arranged on the oil intake line to prevent the fuel from flowing back.

[0036] The hydraulic pump 3 is driven by an electric motor, and the selection of the electric motor should take into account the explosion-proof grade, power size, and viscosity range of applicable oil products, so as to match the parameters of the electric motor. The oil pump should be suitable for fuel with a relatively large viscosity range, and have overpressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com