Supersonic laser deposition micro shot peening method and spraying device

A supersonic laser and shot peening technology, applied in the method and spraying device, in the field of supersonic laser deposition micro shot peening, can solve the problems of low deposition efficiency, poor bonding strength and high porosity, and achieve elimination of high porosity and reduction of porosity. rate, improved wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 A method of supersonic laser deposition micro-peening, specifically comprising the following steps:

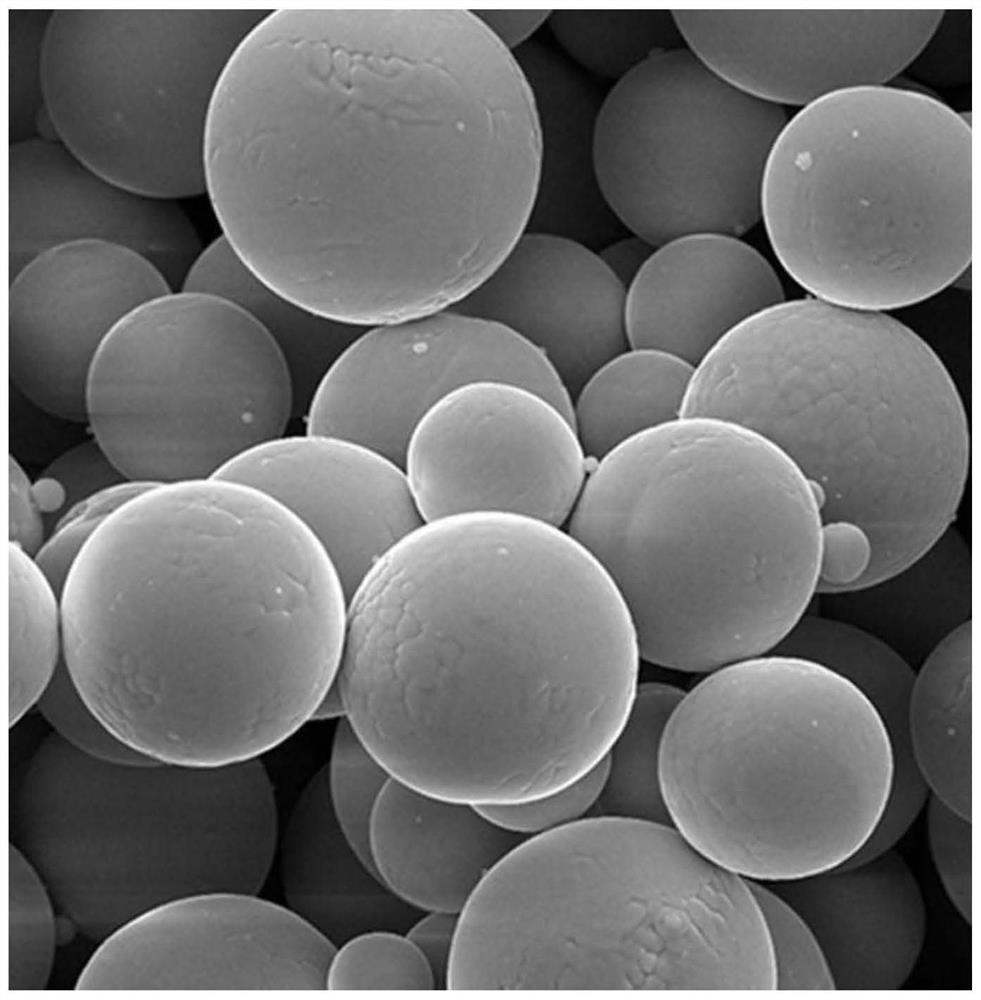

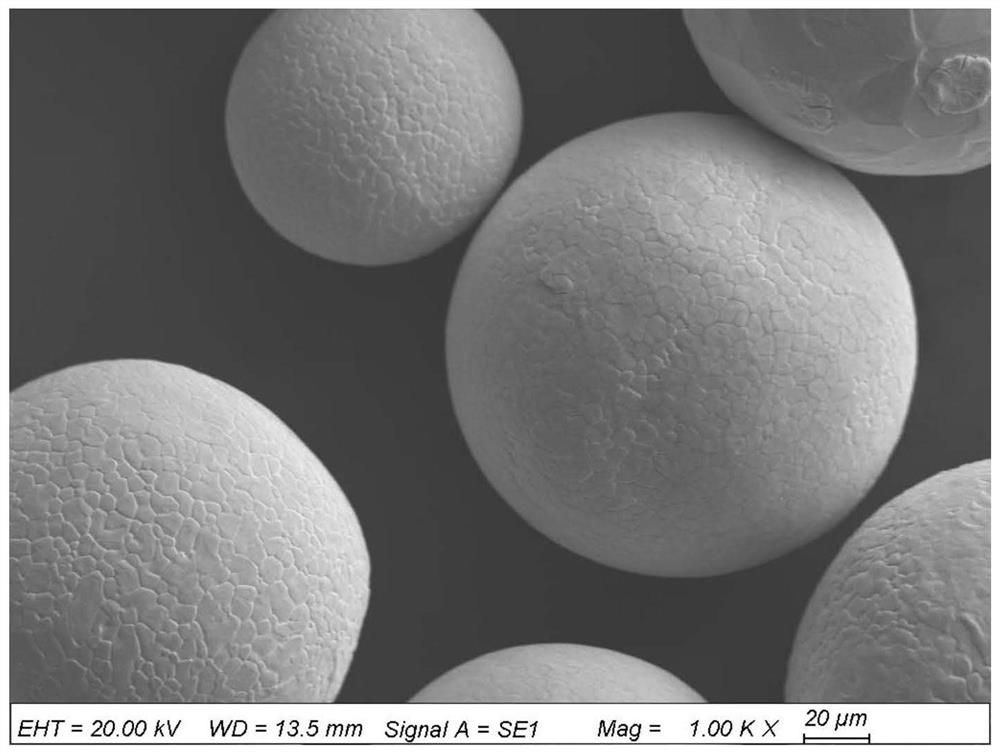

[0044] Take the part to be repaired as the base material, firstly polish the base material, and then use 24# white corundum to perform sandblasting treatment under the air pressure of 1.0MPa to improve the surface roughness and remove surface oxides, and then put it into an ultrasonic cleaning machine Wash to remove surface impurities, then wash with absolute ethanol, then wipe dry and put it in a vacuum drying oven to preheat (temperature 120°C, time 0.5h), and fix the treated substrate on the workbench. Spherical particles of large particle size alumina (particle size is 120 ~ 150μm, such as figure 1 As shown, the alumina volume ratio is 30vol.%) and Cu powder are fully mechanically mixed (ball milled at 300rpm for 30min) and then dried (dried at a drying temperature of 120°C for 3 hours), and then poured into a powder feeder. Set the spray carrier gas (...

Embodiment 2

[0045] Embodiment 2 The spraying device constructed according to the method of supersonic laser deposition micro-peening described in the present invention includes cold spraying equipment 100, laser equipment 200, carrier gas supply equipment 300 and mobile equipment, and the mechanical arm of the mobile equipment is suspended Above the workbench 400, the cold spray equipment 100 includes a powder feeder, a gas heater 3, a cold spray gun 5 and a power supply 4, and the powder feeding port of the powder feeder 2 is connected to the inlet of the cold spray gun 5. The powder port pipeline is connected; the gas heater 3 is provided with a heating channel, and the voltage input end of the gas heater 3 is electrically connected to the voltage output end of the power supply 4;

[0046] The laser device 200 includes a laser head 6 and an infrared detector 7, and the laser head 6 and the cold spray gun 5 are fixedly arranged on the mechanical arm of the mobile device at the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com