Method for preparing graphite-reinforced anti-attrition heat and electricity conduction coating layer by supersonic laser deposition

A supersonic laser, conductive coating technology, applied in coating, metal material coating process, metal processing equipment, etc., can solve the problems of high porosity, reducing the critical deposition rate of powder, and low deposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

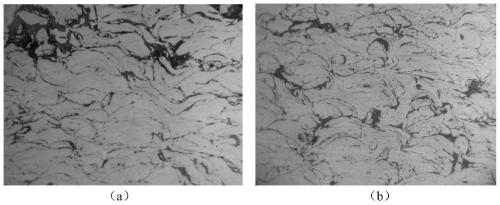

[0040]Take the copper plate (80mm*40mm*5mm) as the base material, firstly carry out the sandblasting treatment on the base material, and use 24# white corundum to carry out the sandblasting treatment under the air pressure of 0.8MPa to improve the surface roughness and remove the surface oxide, and then Clean it in an ultrasonic cleaner to remove surface impurities, then clean it with absolute ethanol, and then wipe it to dry. Fix the treated substrate on the bench. Spherical graphite (particle size is 25μm spherical graphite powder such as figure 1 Shown) (20vol.%) and Cu powder are fully mixed and then dried, then put into the powder feeder. Set the spray carrier gas (N 2 ) pressure is 4MPa, the powder feeding rate is 1.5rpm, the powder preheating temperature is 500°C, the spraying distance is 30mm, and the scanning speed is 10mm / s. Change the laser power (0W, 600W, 800W, 1200W, 1400W, 1600W respectively) during the spraying process. Do single-pass spraying, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com