Wear-resistant and stable flame-retardant super-hydrophobic/super-oleophobic coating as well as preparation and application thereof

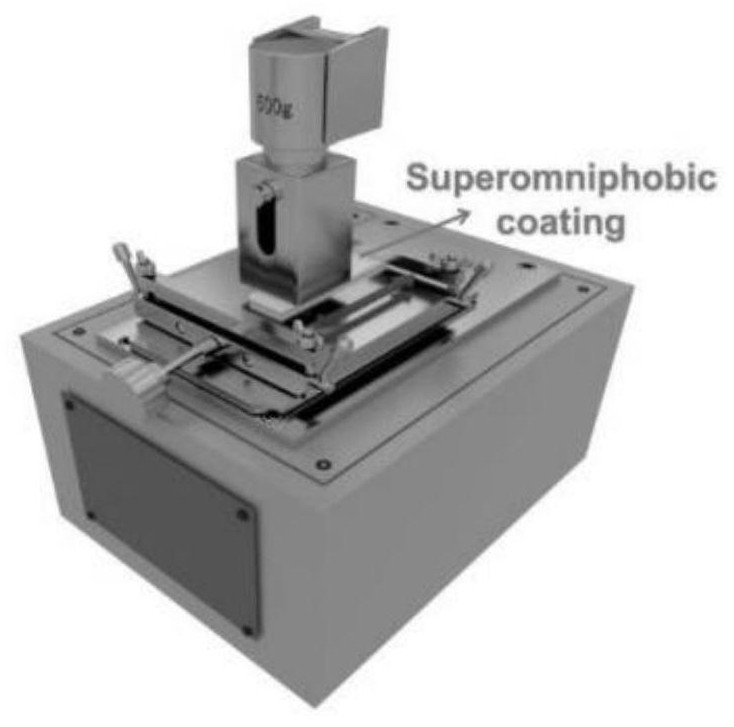

A super-hydrophobic and super-oleophobic technology, used in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of no flame retardant effect, poor adhesion between the coating and the substrate, etc., to reduce fire hazards and reduce heat. The effect of the amount of smoke released and the wear resistance of high-speed friction machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

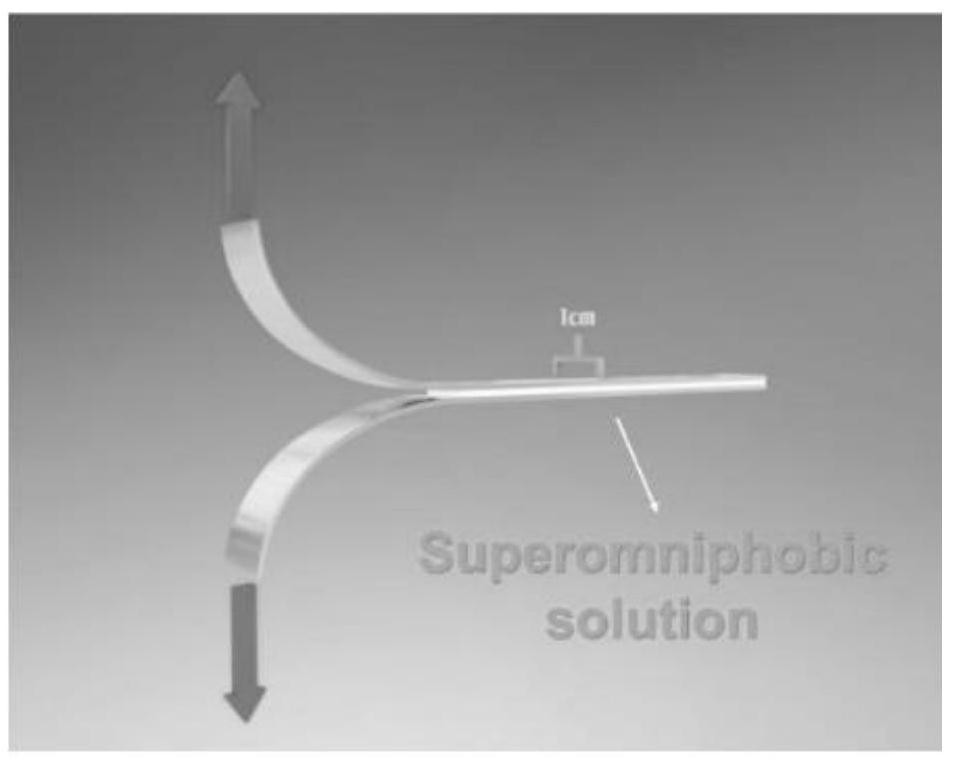

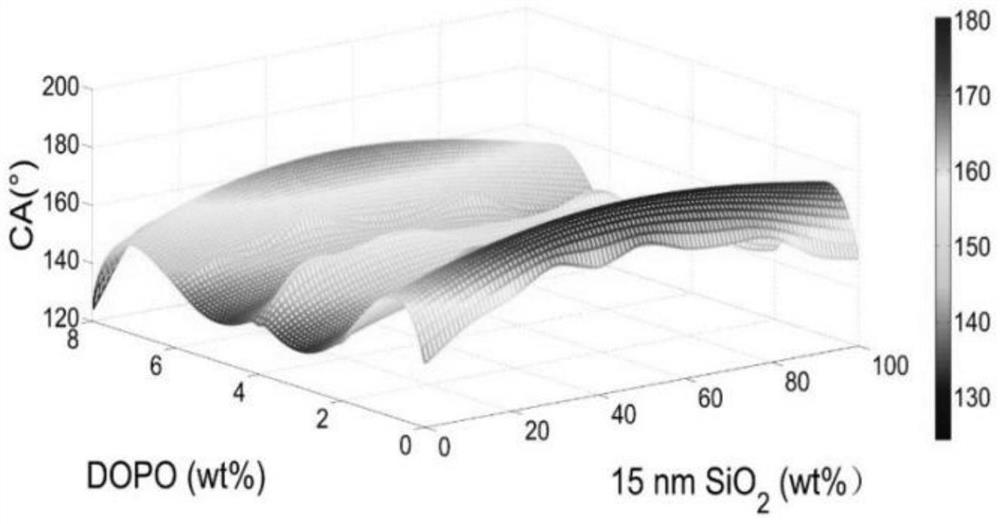

[0106] Preparation of superhydrophobic / superoleophobic suspensions

[0107] First, the 15nm SiO 2 (0.5g), 50nm SiO 2 (0.5 g) and 25 μm α-cellulose were dispersed in a mixed solution containing absolute ethanol (30 mL) and ammonia water (10 mL), and sonicated for 30 minutes. Then TEOS (2 mL) and FAS (1 mL) were added dropwise to the above solution and stirred in a water bath at 60 °C for 6 hours, named solution A.

[0108] Secondly, bisphenol A type epoxy resin (EP, 1.0g) was dissolved in absolute ethanol (5mL) solution and ultrasonically oscillated for 30 minutes to name it solution B. Next, solution B was added to a 60°C water bath In the solution A of the solution A, after fully mixing, quickly inject 0.6mL TEOS and 0.6mL FAS into the suspension, and stir at 60°C for 2h, called solution C.

[0109] Preparation of superhydrophobic / superoleophobic suspensions

[0110] Dissolve 0.535 mL of heptafluorobutyric acid (HFA) and 0.57 mL of 3-(2-aminoethylamino)propyltrimethoxysil...

Embodiment 2

[0160] Preparation of bilayer superhydrophobic suspension (top layer)

[0161] 15nm SiO 2 (0.45g), 50nm SiO 2 (0.45 g) and 25 μm α-cellulose (0.45 g) were dispersed in a mixed solution containing absolute ethanol (30 mL) and ammonia water (10 mL) by stirring, and ultrasonicated in a 60° C. water bath for 30 minutes. Then TEOS (3 mL) and FAS (0.9 mL) were added dropwise to the above solution and stirring was continued for 4 hours, referred to as solution A. Dissolve bisphenol A type epoxy resin EP (5.0g) in anhydrous ethanol (25mL) solution by ultrasonic vibration for 1 hour, called solution B, then add solution B to solution A in a water bath at 60°C for 1 hour, fully After dissolving, 0.6 mL TEOS and 0.6 mL FAS were added dropwise into the above mixed solution and stirred for 1 hour, which was called solution C. At the same time, in another flask, add 2.8mL AS to 10mL absolute ethanol at 60°C, then add 0.3mL FAS dropwise, and react for 1h as a curing agent. Finally, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com