Environment-friendly polyethylene garbage bag easy to decompose and preparation process

A preparation process and technology of garbage bags, which are applied in the field of garbage bags, can solve the problems of polyethylene materials being difficult to degrade, poor thermoplasticity, and unfavorable popularization and use, and achieve the effect of increasing degradable performance, improving rheological properties, and facilitating popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An environmentally friendly polyethylene garbage bag that is easy to decompose, the formula includes: high-density polyethylene, modified starch, biochar, lignocellulose aerogel, silane coupling agent and silanized bentonite, the parts by weight of each component They are: 25 parts of starch, 60 parts of high-density polyethylene, 25 parts of biochar, 5 parts of lignocellulose airgel, 3 parts of silane coupling agent and 10 parts of silanized bentonite.

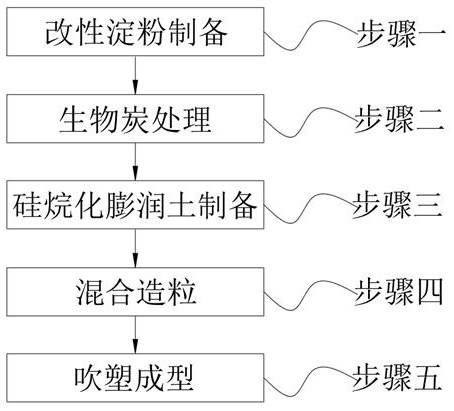

[0022] A preparation process of environmentally friendly polyethylene easily decomposed garbage bags, including step 1, preparation of modified starch; step 2, biochar treatment; step 3, preparation of silanized bentonite; step 4, mixing and granulation; Molded.

[0023] Wherein in the above-mentioned step 1, at first, starch and nano-silicon dioxide are uniformly mixed according to the mass ratio of 25:1, and then microwave treatment is used for 5-10 minutes to make a starch mixture, and the starch used is potato star...

Embodiment 2

[0029] An environmentally friendly polyethylene garbage bag that is easy to decompose, the formula includes: high-density polyethylene, modified starch, biochar, lignocellulose aerogel, silane coupling agent and silanized bentonite, the parts by weight of each component They are: 25 parts of starch, 75 parts of high-density polyethylene, 20 parts of biochar, 6 parts of lignocellulose airgel, 5 parts of silane coupling agent and 10 parts of silanized bentonite.

[0030] A preparation process of environmentally friendly polyethylene easily decomposed garbage bags, including step 1, preparation of modified starch; step 2, biochar treatment; step 3, preparation of silanized bentonite; step 4, mixing and granulation; Molded.

[0031]Wherein in the above-mentioned step 1, at first, starch and nano-silicon dioxide are uniformly mixed according to the mass ratio of 25:1, and then microwave treatment is used for 5-10 minutes to make a starch mixture, and the starch used is potato starc...

Embodiment 3

[0037] An environmentally friendly polyethylene garbage bag that is easy to decompose, the formula includes: high-density polyethylene, modified starch, biochar, lignocellulose aerogel, silane coupling agent and silanized bentonite, the parts by weight of each component They are: 20 parts of starch, 65 parts of high-density polyethylene, 20 parts of biochar, 8 parts of lignocellulose airgel, 7 parts of silane coupling agent and 12 parts of silanized bentonite.

[0038] A preparation process of environmentally friendly polyethylene easily decomposed garbage bags, including step 1, preparation of modified starch; step 2, biochar treatment; step 3, preparation of silanized bentonite; step 4, mixing and granulation; Molded.

[0039] Wherein in the above-mentioned step 1, at first, starch and nano-silicon dioxide are uniformly mixed according to the mass ratio of 25:1, and then microwave treatment is used for 5-10 minutes to make a starch mixture, and the starch used is potato star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com