Catalyst for preparing plasticizer alcohol from synthesis gas as well as preparation method and application of catalyst

A catalyst and synthesis gas technology, which is applied in the field of synthesis gas to higher alcohols, can solve the problems of many by-products, low alcohol selectivity, poor catalyst stability, etc., and achieves the effects of convenient operation, convenient particle size control, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

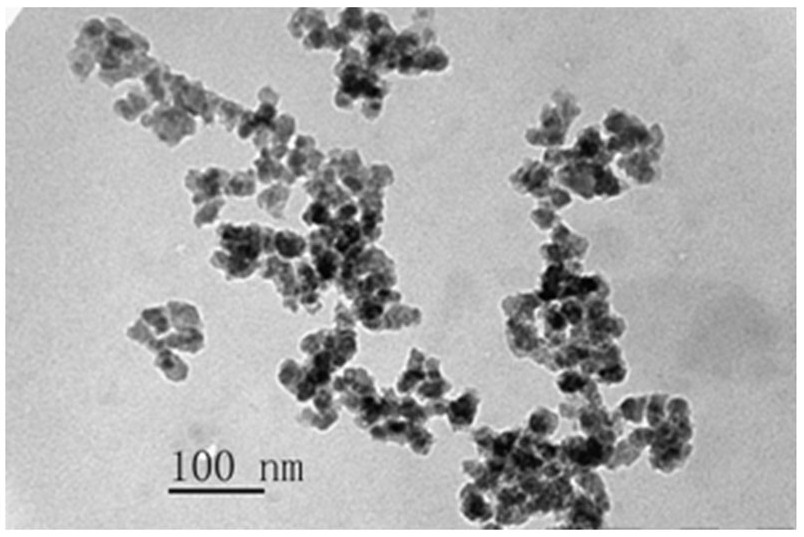

Image

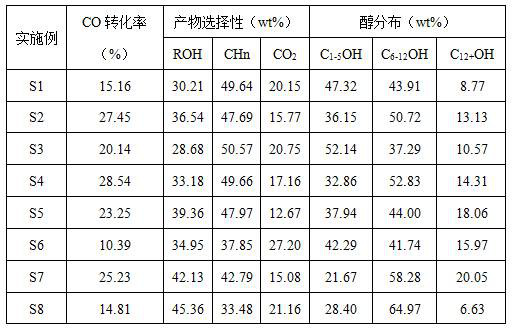

Examples

Embodiment 1

[0028] (1) According to the catalyst composition, 2.62g Cu(acac) 2 (copper acetylacetonate), 10.68g Co(acac) 3 (Cobalt acetylacetonate) was dissolved in 100mL oleylamine and 50mL oleic acid and stirred evenly, heated the mixture to 220°C for 120min under reflux, then set the temperature to 200°C for 120min; after cooling to room temperature, added methanol and centrifuged After that, get Cu 1 m 1 nanoparticles.

[0029] (2) Add Cu in the above (1) 1 m 1 Nanoparticles were dispersed with chloroform; weighed 1g of cetyltrimethylammonium bromide CTAB dissolved in 100mL of water, and then added to Cu 1 m 1 In the nanoparticle chloroform dispersion, after ultrasonic vibration for 10 minutes, stir at 65°C to completely volatilize the chloroform.

[0030] (3) Add 100mL of deionized water and 3g of polyvinylpyrrolidone (PVP) to the above (2) particle suspension or water-soluble particles and stir, then add 100mL of methanol to obtain A solution; according to the catalyst compos...

Embodiment 2

[0033] (1) According to the catalyst composition, 2.62g Cu(acac) 2 (copper acetylacetonate), 10.59g Fe(acac) 3 Dissolve in 100mL oleylamine and 100mL oleic acid and stir evenly, heat the mixture to 230°C for 60min under reflux, then set the temperature to 210°C for 60min; after cooling to room temperature, add ethanol and centrifuge to obtain Cu 1 m 1 nanoparticles.

[0034] (2) Add Cu in the above (1) 1 m 1 Nanoparticles were dispersed with chloroform; weighed 2g cetyltrimethylammonium bromide CTAB dissolved in 100mL water, then added to Cu 1 m 1 In the nanoparticle chloroform dispersion, after ultrasonic vibration for 10 minutes, stir at 65°C to completely volatilize the chloroform.

[0035] (3) Add 100mL of deionized water and 1g of polyvinylpyrrolidone (PVP) to the above (2) particle suspension or water-soluble particles and stir, then add 100mL of ethanol to obtain A solution; according to the catalyst composition, 7.26g of Cu(NO 3 ) 2 ·3H 2 O, 2.91g Co(NO 3 ) ...

Embodiment 3

[0038] (1) According to the catalyst composition, 5.24g Cu(acac) 2 (copper acetylacetonate), 14.12g Fe(acac) 3 Dissolve in 300mL oleylamine and 100mL oleic acid and stir evenly, heat the mixture to 250°C for 60min under reflux, then set the temperature to 220°C for 90min; add ethanol after cooling to room temperature and centrifuge to obtain Cu 1 m 1 nanoparticles.

[0039] (2) Add Cu in the above (1) 1 m 1 Nanoparticles were dispersed with chloroform; 6g Tween 20 was weighed and dissolved in 200mL water, then added to Cu 1 m 1 In the nanoparticle chloroform dispersion, after ultrasonic vibration for 10 minutes, stir at 65°C to completely volatilize the chloroform.

[0040] (3) Add 200mL of deionized water and 2g of polyvinylpyrrolidone (PVP) to the above (2) particle suspension or water-soluble particles and stir, then add 300mL of ethanol to obtain A solution; according to the catalyst composition, 4.84g of Cu(NO 3 ) 2 ·3H 2 O, 5.82g Co(NO 3 ) 2 ·6H 2 O, 8.58g Zr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com