Preparation method of high dispersibility superfine silver powder with adjustable grain diameter

A high-dispersion, ultra-fine silver technology, applied in the field of liquid-phase preparation of ultra-fine silver powder, can solve the problems of difficulty in controlling powder dispersion, unfavorable for large-scale industrial production, low output per unit volume, etc., and achieve densification and shrinkage. The effect of low rate, excellent end product performance and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] First, the basic scheme of the preparation method of the present invention is briefly described: a preparation method of highly dispersed ultrafine silver powder with adjustable particle size, the steps are: 1. Dissolving silver nitrate and surfactant in water is configured into silver solution A; ②. Dissolve ascorbic acid, pH regulator and surfactant in water to prepare reducing solution B; ③. Prepare alkaline pH regulator in alkaline aqueous solution C; ④. Add liquid C and Liquid A, make the silver powder grow evenly;

[0015] Or: ①, dissolving silver nitrate and surfactant in water to configure silver solution A; ②, dissolving ascorbic acid and surfactant in water to configure reducing solution B1; ③, configuring alkaline pH regulator in alkaline aqueous solution C ; ④, configure the pH regulator into an aqueous solution with a certain pH value as the reaction bottom liquid D; ⑤, add liquid A, liquid B1 and liquid C to liquid D dropwise within the specified time, so ...

Embodiment 1

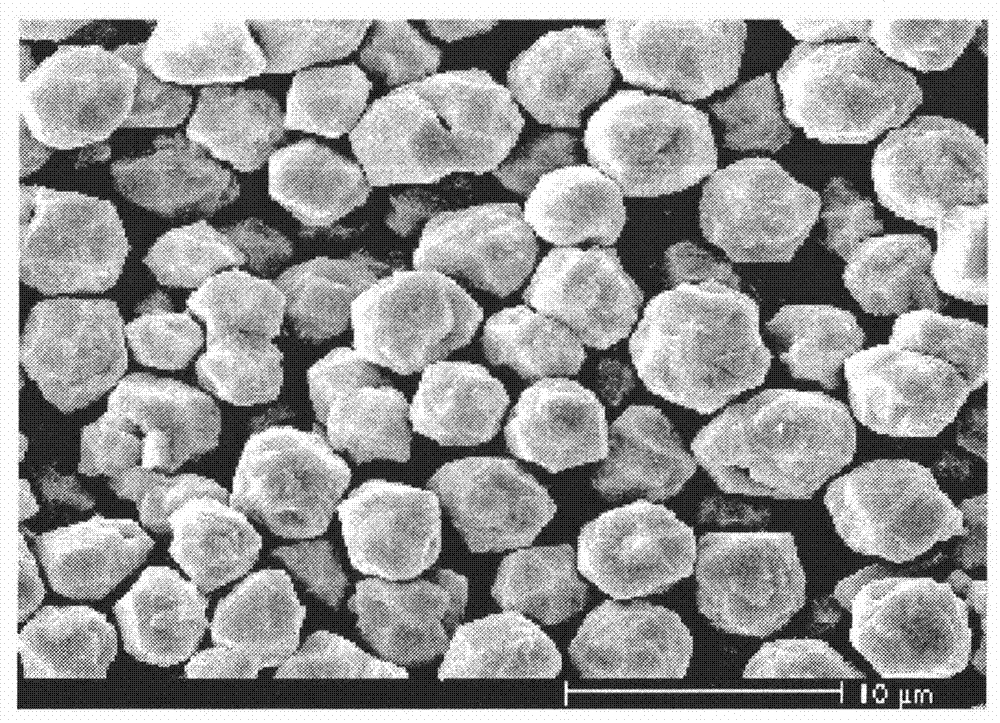

[0017] 157gAgNO 3 Dissolve 1 g of gum in 1 L of deionized water (hereinafter referred to as water), stir and dissolve to obtain a silver solution. Add 120 g of ascorbic acid and 2 g of gum into 1 L of water, add a pH regulator to adjust the pH to 3, and obtain a reducing solution. Control the reaction temperature at (30-35) ° C, drop the silver-containing solution into the reducing solution within 30 minutes, and add sodium hydroxide solution dropwise at the same time to control the reaction pH value to 3±0.5, stir for 15 minutes after the addition, and let stand Precipitate, wash the powder with water until the conductivity of the filtrate is less than 100μs / cm, filter and dry at 60°C, and sieve to obtain silver powder. Powder test results: see the attached SEM picture of the powder figure 1 , average particle size 4.0μm; tap density 5.1g / ml; particle size distribution S.D. / D50 is 0.425.

Embodiment 2

[0019] The amount of material used in Example 1 is enlarged by 200 times, and other processes are consistent with Example 1. Powder testing results: the average particle size of the powder is 3.8 μm; the tap density is 4.9 g / ml; the particle size distribution S.D. / D50 is 0.451.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com