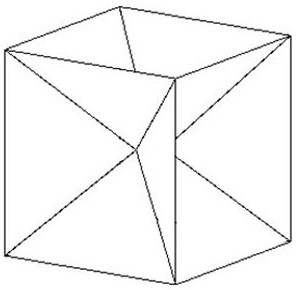

A kind of concave polyhedron streamline suspension lightweight filter material, preparation method and application

A light-weight filter material and concave polyhedron technology, applied in separation methods, chemical instruments and methods, loose filter material filters, etc., can solve the problems of poor compression permanent deformation, easy hardening and flattening of cylinders, and difficulty in cleaning, etc. problems, achieve low compression set, reduce head loss, and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] 1) EVA hydrolysis

[0053] Dissolve 60 parts of EVA in 80 parts of toluene, heat up to reflux state, add 65 parts of ethanol solution dissolved with sodium hydroxide, the concentration of sodium hydroxide is 2mol / L, react at constant temperature for 5h, add 15wt% hydrochloric acid dropwise to pH to 7, cooled to room temperature, poured the reaction liquid into 300 parts of water, stirred until no more precipitates were precipitated, dried the precipitates in vacuum at 80°C, and crushed to 80 μm, washed with water, filtered, and dried again. Repeat this twice to obtain dry powder for later use; The test hydrolysis degree is 96.0%.

[0054] 2) Esterification of EVA hydrolyzate

[0055] Dissolve the dry powder obtained in step 1) in 80 parts of toluene, add 13.4 parts of alanine and 31 parts of p-toluenesulfonic acid, heat up to 110°C and keep stirring until no more water condenses and separates out, then naturally cool to room temperature, Slowly pour the reaction solut...

preparation example 2

[0057] The rest are the same as in Preparation Example 1, except that 13.4 parts of alanine are replaced by 11.25 parts of glycine.

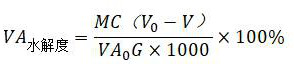

[0058] Using phenolphthalein as an indicator, use 0.1mol / L HCl solution to titrate the reaction mixture in step 1) cooled to room temperature until the phenolphthalein changes color. At the same time, do a blank experiment, record the volume of hydrochloric acid solution used for titration, and repeat three times to calculate the consumption of hydrochloric acid solution The average value of the volume, refer to the following formula to calculate the consumption of VA in EVA, that is, the degree of hydrolysis of VA in EVA.

[0059]

[0060] Among them, M is the relative molecular mass of VA; C is the concentration of hydrochloric acid used in titration, mol / L; V0 is the volume of hydrochloric acid consumed by the blank sample, ml; V is the volume of hydrochloric acid consumed in titration, ml; VA 0 is the total content of VA in EVA; G is the ...

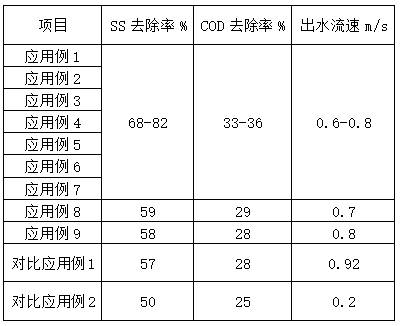

Embodiment 1

[0063] S1. Add 30 parts of the modified copolymer prepared in Preparation Example 1 and 70 parts of ethylene-vinyl acetate copolymer to a double-roll mill with a preheating temperature of 120°C, knead for 3 minutes, and add 5.92 parts of 1,3 - Bis(3-glycidyl etheroxypropyl) tetramethyldisiloxane, 2.08 parts of epoxy-terminated silicone oil, kneading for 2 minutes, adding 5 parts of azodicarbonamide, 1.5 parts of DCP, 3 parts of zinc oxide , 8 parts of calcium stearate continue to knead for 5 minutes, 3 parts of talcum powder, and the thin slices are 1.7mm thick slices, which are cut to obtain pellets;

[0064] S2. Put the pellets obtained in the previous step into a 5mm×5mm×5mm mold preheated to 160°C in advance, foam at 160°C for 6 minutes, and the molding pressure is 10MPa, open the mold, and then place it in a mold at 80°C Heat treatment in a drying oven for 6 hours, take it out and place it at room temperature for 24 hours to obtain a lightweight filter material of 5mm×5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com