Preparation method of maleimide

A technology of maleimide and maleic anhydride, applied in organic chemistry and other directions, can solve the problems of many by-products, low yield, troublesome post-processing, etc., and achieves short experimental route, strong experimental operability, and safe raw materials. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to the preparation method of the maleimide of the embodiment of the present invention, comprising:

[0030] Step S1, reacting maleic anhydride with p-methoxybenzylamine to generate 3-(4-methoxybenzylcarbamoyl)acrylic acid.

[0031] That is to say, firstly, intermediate 1, namely 3-(4-methoxybenzylcarbamoyl)acrylic acid was synthesized by using maleic anhydride and p-methoxybenzylamine as raw materials.

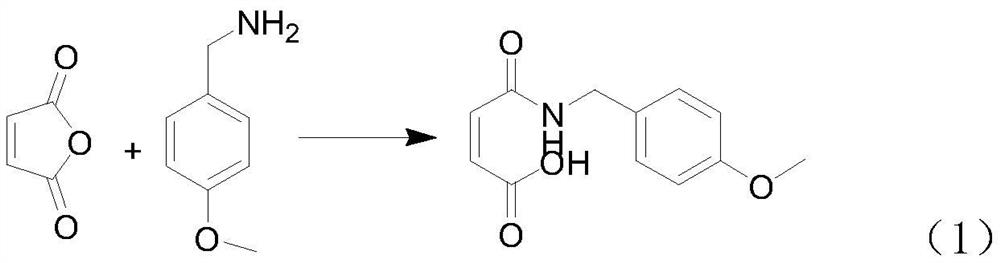

[0032] Its reaction formula is shown in following formula (1):

[0033]

[0034] Specifically, for example, the maleic anhydride can be added to the DMF solution to fully dissolve, and the p-methoxybenzylamine is added dropwise therein to generate the 3-(4-methoxybenzylaminomethyl acyl) acrylic acid.

[0035] That is, the above synthetic reaction was carried out in DMF medium to generate Intermediate 1.

[0036] Wherein, the molar ratio of maleic anhydride to p-methoxybenzylamine is 1:0.8-1.2, for example, the above-mentioned synthesis reaction can occur...

Embodiment 1

[0062](1) Preparation of compound 3-(4-methoxybenzylcarbamoyl)acrylic acid

[0063] Take a 1L reaction bottle, add maleic anhydride (30g, 0.31mol, 1.0eq) into DMF (120mL, 4P), and add p-methoxybenzylamine (42.5g, 0.31mol, 1.0eq ), stirred for 6 hours and the reaction ended. Pour the reaction solution into an appropriate amount of ice water to precipitate solids, filter them with suction, wash them once with water, and dry the solids to obtain 67g of 3-(4-methoxybenzylcarbamoyl)acrylic acid with a yield of 92%.

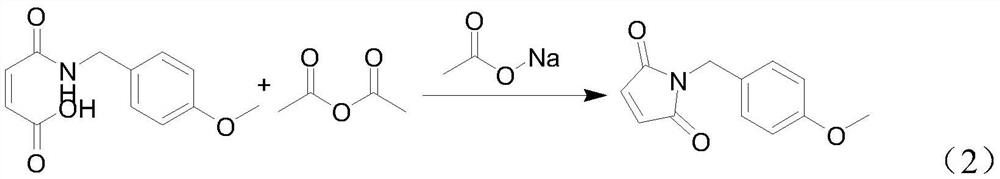

[0064] (2) Preparation of compound 1-(4-methoxybenzyl)maleimide

[0065] Take a 1L reaction bottle and add 3-(4-methoxybenzylcarbamoyl)acrylic acid (67.0g, 0.28mol, 1.0eq) and sodium acetate (13.8g, 0.168mol, 0.6eq) into the acetic anhydride solution (85.7 g, 0.84mol, 3.0eq), the temperature of the oil bath was controlled at 90-100°C for 2 hours. After the reaction is complete, add ice water dropwise to the reaction solution to quench acetic anhydride, continue to s...

Embodiment 2

[0071] (1) Preparation of compound 3-(4-methoxybenzylcarbamoyl)acrylic acid

[0072] Take a 1L reaction bottle and add maleic anhydride (98g, 1mol, 1.0eq) into DMF (400mL, 4P), and add p-methoxybenzylamine (137.1g, 1mol, 1.0eq) dropwise at a temperature of 20-25°C, After stirring for 7 hours, the reaction was completed. Pour the reaction solution into an appropriate amount of ice water to precipitate solids, filter them with suction, wash them with water once, and dry the solids to obtain 221 g of 3-(4-methoxybenzylcarbamoyl)acrylic acid with a yield of 94%.

[0073] (2) Preparation of compound 1-(4-methoxybenzyl)maleimide

[0074] Take a 1L reaction bottle and add 3-(4-methoxybenzylcarbamoyl)acrylic acid (221.0g, 0.94mol, 1.0eq) and sodium acetate (46.2g, 0.56mol, 0.6eq) into the acetic anhydride solution (287.7 g, 2.82mol, 3.0eq), the temperature of the oil bath was controlled at 90-100°C for 3 hours. After the reaction was complete, add ice water dropwise to the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com