Optical element polishing die filling adhesive and preparation method thereof

A technology of optical components and filling glue, which is applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of easy deformation of polishing molds, low processing efficiency, and low processing quality, and achieve stable polishing surface quality, enhanced stability, The effect of strong heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

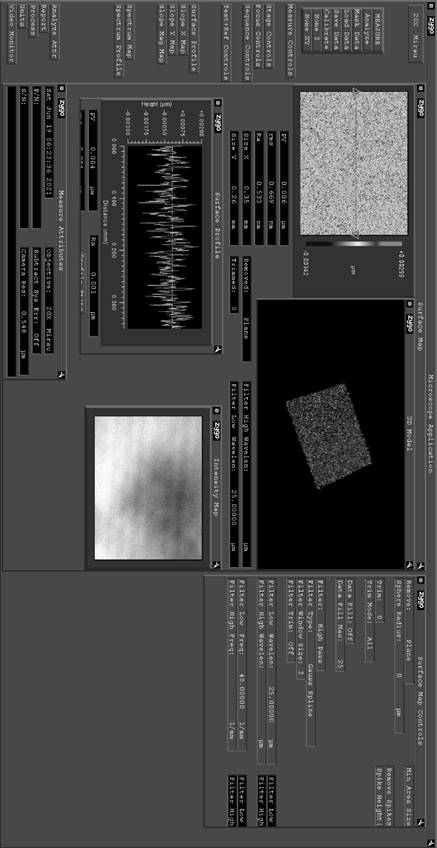

Image

Examples

Embodiment 1

[0039] Prepare 10 kg of asphalt, 1 kg of beeswax, 7 kg of rosin and 1 kg of alumina with a particle size of 0.1um by weight, and prepare the polishing mold filling compound according to the following process steps:

[0040] S1. Melt the rosin at a temperature of 60-80°C, stir while adding beeswax, wait until the beeswax and rosin are mixed evenly, and then add alumina powder while stirring to obtain a mixture;

[0041] S2. Melt the asphalt at a temperature of 80-150°C and add it to the mixture obtained in step S1, continue to stir evenly, and continue to heat;

[0042] S3. Keep the asphalt-added mixture obtained in step S2 at a temperature of 350° C. for 60 hours to obtain a polishing mold filling compound with a microporous structure uniformly distributed on the surface.

[0043] The pore diameter of the microporous structure on the surface of the polishing film filler described in this embodiment is 460-524 μm.

[0044] The resulting polishing mold is filled with glue to ma...

Embodiment 2

[0046] Prepare 5 kilograms of asphalt, 0.5 kilograms of beeswax, 3.5 kilograms of rosin and 1 kilogram of alumina with a particle size of 0.1um by weight, and prepare the polishing mold filling glue according to the following process steps:

[0047] S1. Melt the rosin at a temperature of 60-80°C, stir while adding beeswax, wait until the beeswax and rosin are mixed evenly, and then add alumina powder while stirring to obtain a mixture;

[0048] S2. Melt the asphalt at a temperature of 80-150°C and add it to the mixture obtained in step S1, continue to stir evenly, and continue to heat;

[0049] S3. Heat the asphalt-added mixture obtained in step S2 at a temperature of 400° C. for 35 hours to obtain a polishing mold filling compound with a microporous structure evenly distributed on the surface.

[0050] The pore diameter of the microporous structure on the surface of the polishing film filler described in this example is 184-263 μm.

Embodiment 3

[0052] Prepare 15 kilograms of asphalt, 1.5 kilograms of beeswax, 10 kilograms of rosin and 5 kilograms of alumina with a particle size of 0.1um by weight, and prepare the polishing mold filling glue according to the following process steps:

[0053] S1. Melt the rosin at a temperature of 60-80°C, stir while adding beeswax, wait until the beeswax and rosin are mixed evenly, and then add alumina powder while stirring to obtain a mixture;

[0054] S2. Melt the asphalt at a temperature of 80-150°C and add it to the mixture obtained in step S1, continue to stir evenly, and continue to heat;

[0055]S3. Heat the asphalt-added mixture obtained in step S2 at a temperature of 500° C. for 100 hours to obtain a polishing mold filling compound with evenly distributed micropore structure on the surface.

[0056] The pore diameter of the microporous structure on the surface of the polishing film filler described in this embodiment is 230-356 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com