High-linearity conductive coating sponge piezoresistive sensor and preparation method thereof

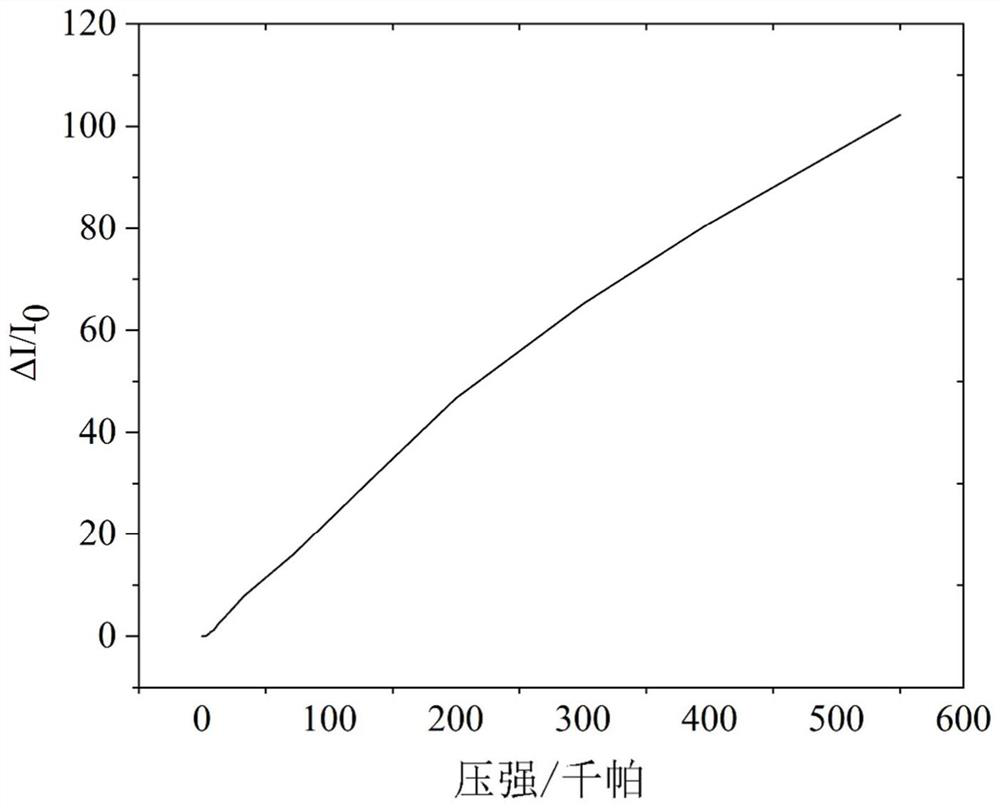

A piezoresistive sensor and conductive coating technology, applied in the field of conductive coating sponge piezoresistive sensors and their preparation, can solve problems such as poor sensor linearity, achieve good coating stability, high linearity sensitivity, and avoid coating peeling off effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

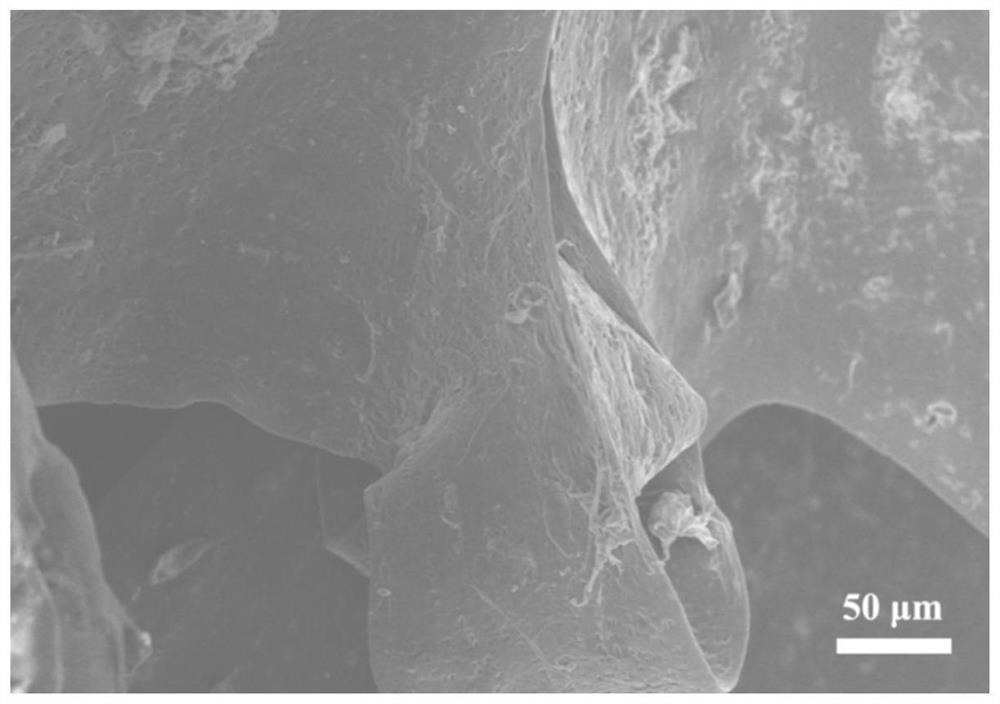

[0029] In step (1), select a porosity of 85% and a density of 0.118 g / cm 3 Put the polyurethane sponge in deionized water for 10 minutes, take it out and dry it at 60°C for 1 hour, then put the sponge in ethanol and ultrasonically clean it for 10 minutes, take it out and dry it at 60°C for 30 minutes, and wash it Polyurethane sponge cut into small pieces of 1 cm×1 cm×1 cm;

[0030] Step (2), magnetically stir the polyethylene oxide aqueous solution with a mass fraction of 3% at 60°C for 2 hours to completely dissolve the polyethylene oxide. After cooling to room temperature, add lithium chloride at a mass fraction of 20%, and magnetically stir again 2h mixed uniformly to obtain polyoxyethylene-lithium chloride aqueous solution;

[0031] Step (3), put the small piece of polyurethane sponge prepared in step (1) into a plasma generating device, treat it with oxygen plasma for 1 min, and then immerse it in the polyethylene oxide-lithium chloride aqueous solution prepared in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com