Coating and sanding process of solid wood strips

A sanding and coating technology, which is applied to wood processing equipment, abrasive belt grinders, manufacturing tools, etc., can solve the problems of poor surface coating quality of solid wood strips, unsandable wooden strips, and unsatisfactory methods. , to achieve the effect of improving surface quality, improving quality and improving sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

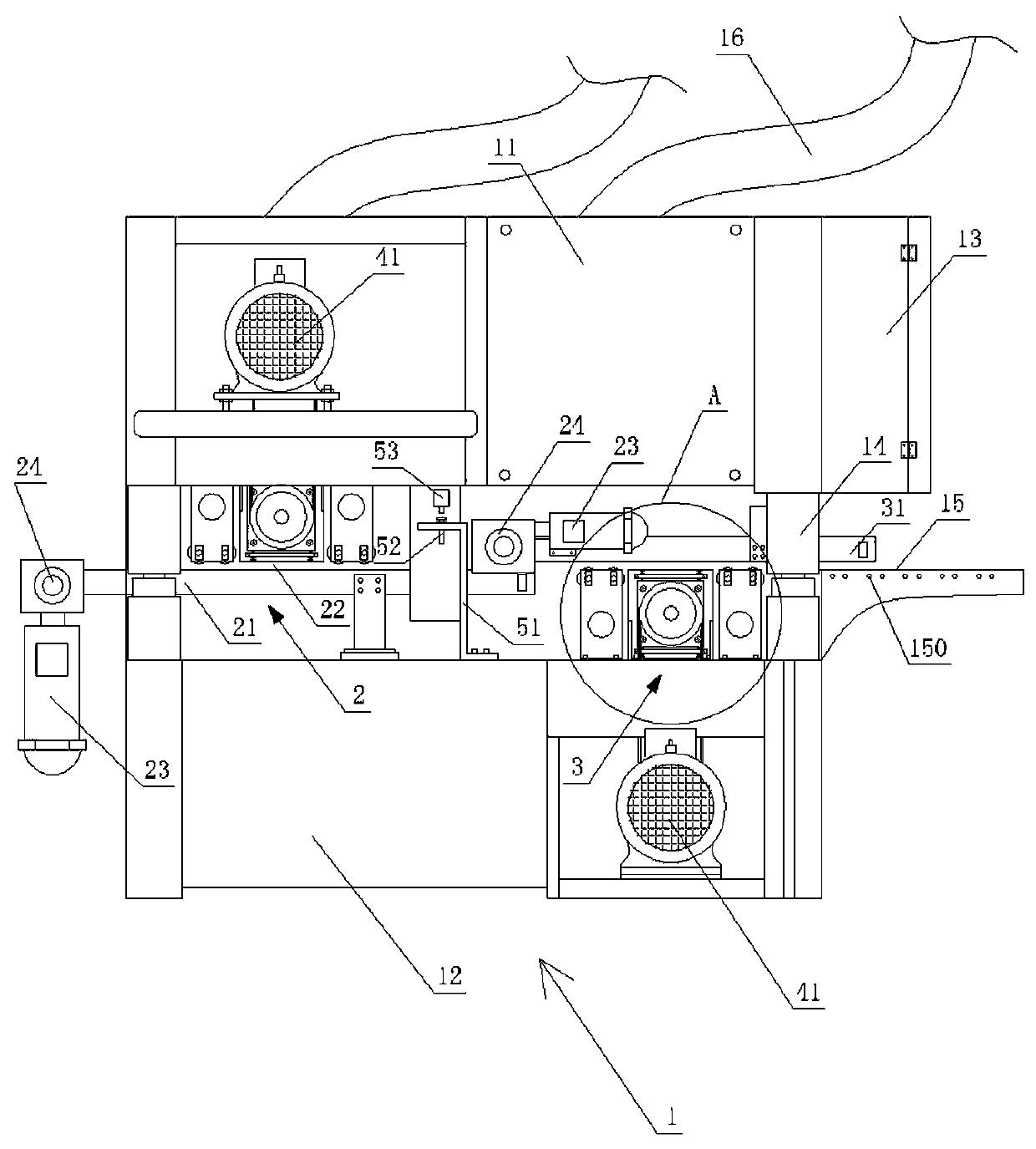

[0025] A coating and sanding process for solid wood strips, comprising the following steps: 1) pre-processing natural wood to make blanks; natural wood is pine or fir, which is cut, assembled, pressed, repaired, Made by sanding and cutting process.

[0026] 2) Mix calcium powder and coating glue to make the first coating slurry, and then evenly coat the first coating slurry on the blank, so that the outer surface of the blank forms the first coating, and the first coating The thickness of the layer is controlled at 0.4 mm; the first coating slurry is made by mixing calcium powder and coating glue, the coating glue is water-based white latex, and the weight ratio of the calcium powder and water-based white latex is 2.8:0.8.

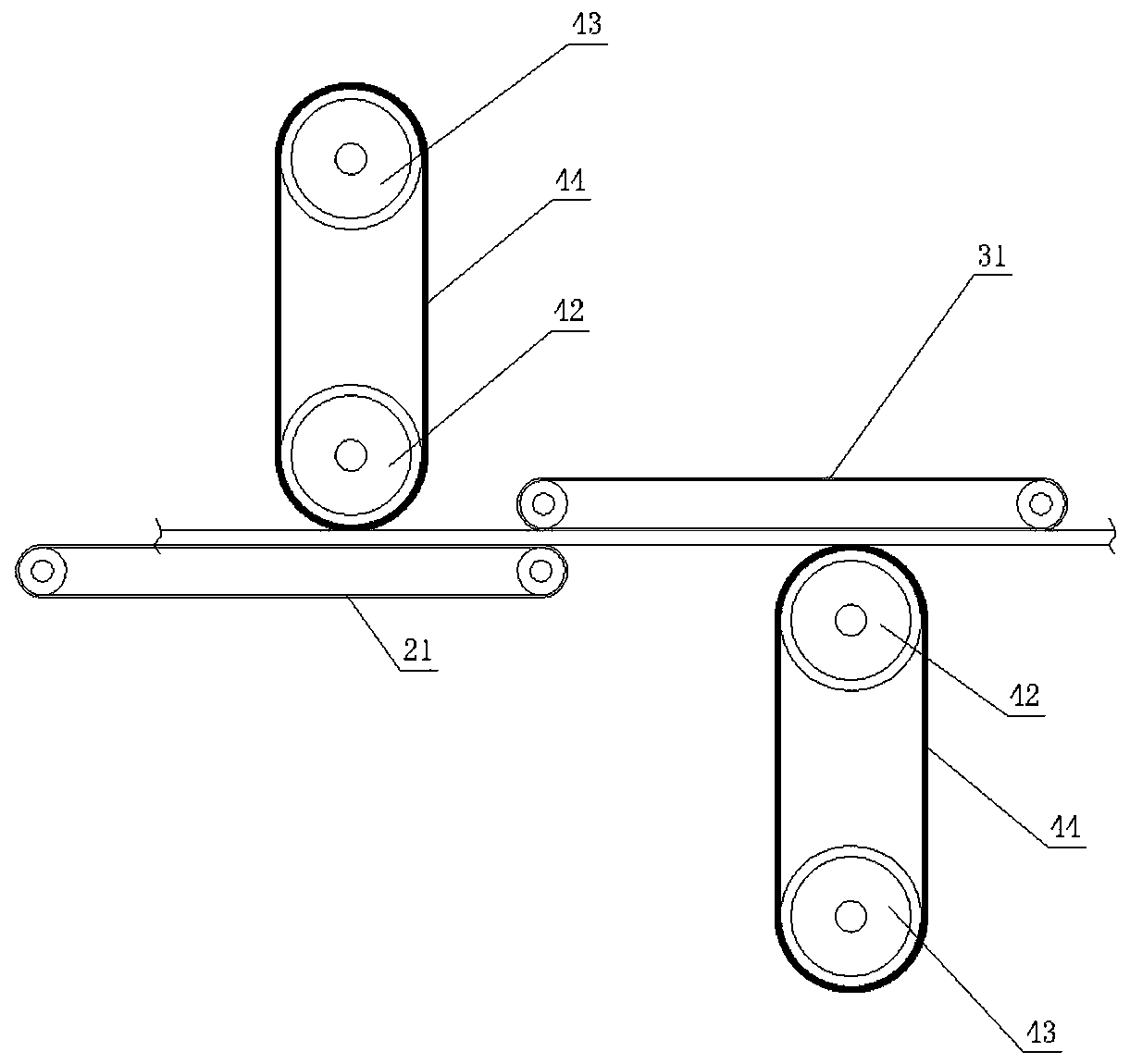

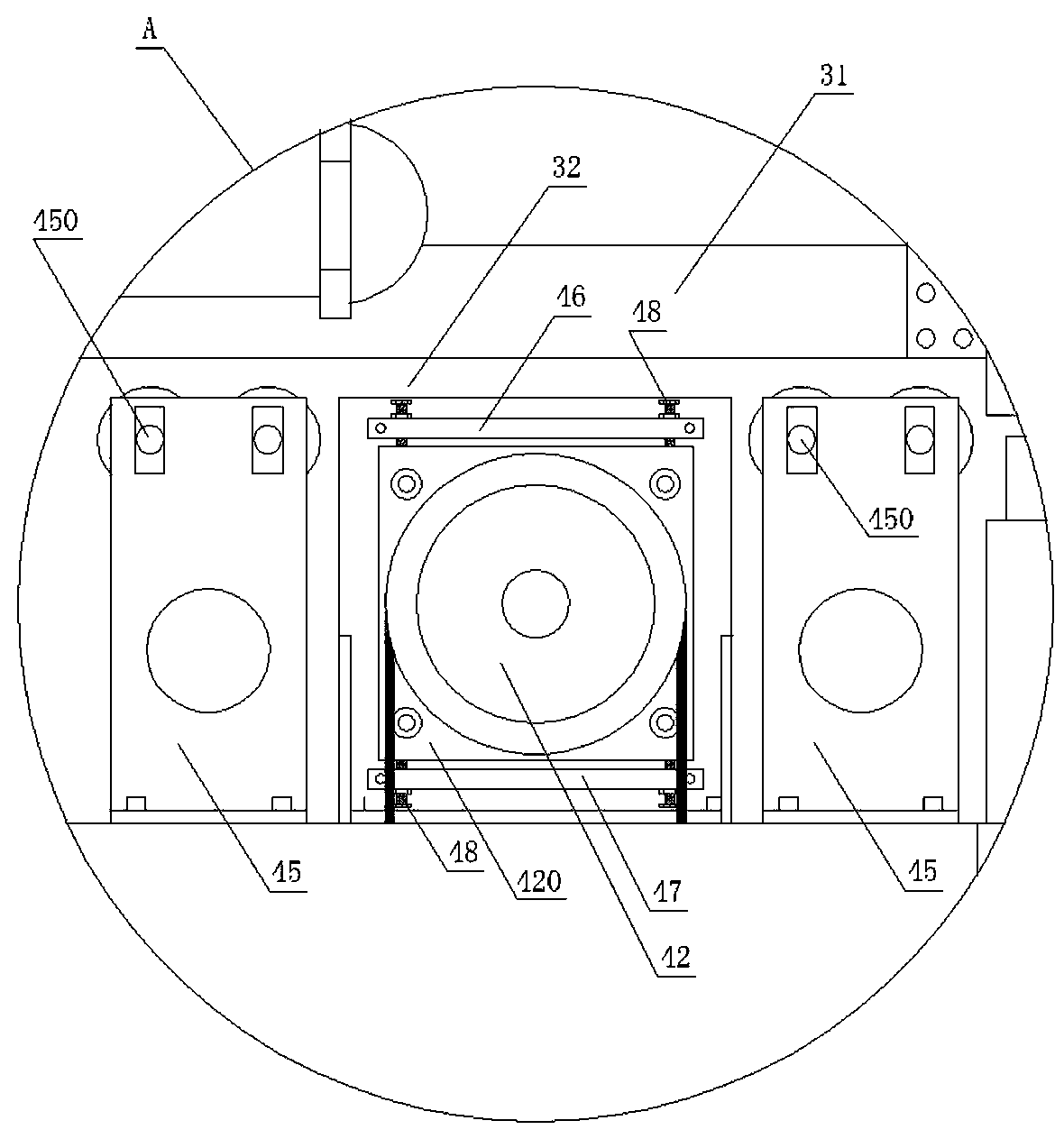

[0027] 3) The blank with the first coating is subjected to the first asynchronous automatic sanding treatment, first sanding the back of the blank, and then sanding the front of the blank.

[0028] 4) Mix calcium powder and coating glue to make a second c...

Embodiment 2

[0036] The implementation of this embodiment and embodiment one is basically the same, and the difference is: the thickness of the first coating is controlled at 0.5mm; the weight ratio of the calcium powder and the water-based white latex of the first coating slurry: 3: 1. The thickness of the second coating is controlled at 0.2 mm; the weight ratio of calcium powder and water-based white latex of the second coating slurry is 2:1.

Embodiment 3

[0038] The implementation of this embodiment and embodiment one is basically the same, the difference is: the thickness of the first coating is controlled at 0.6mm; the weight ratio of calcium powder and water-based white latex of the first coating slurry: 3.2: 1.2. The thickness of the second coating is controlled at 0.3 mm; the weight ratio of calcium powder and water-based white latex of the second coating slurry is 2.2:1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com