Method for improving bonding strength of wear-resistant protective coating on surface of insulating substrate

A technology of insulating substrate and protective coating, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve problems such as damage to coating quality, micro-arc discharge, breakdown, etc., to reduce coating stress , control energy, reduce the effect of charging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] S1, substrate cleaning: place the alumina insulating substrate 1 in acetone, deionized water and ethanol in sequence for ultrasonic cleaning for 15 minutes each, and then dry it for later use.

[0040] S2, strong beam argon ion bombardment: place the aluminum oxide substrate on the substrate stage of vacuum ion plating, vacuumize, and the background vacuum reaches 5×10 -4 Pa, the substrate temperature is heated to 300°C, the argon gas is introduced at 100 sccm, the column arc shield is closed, the column arc Ti target is opened, and the auxiliary anode ion source is connected, the ion source current is 80A, the negative bias voltage amplitude of the substrate is 300V, and the argon The ion etching cleaning time is 40min.

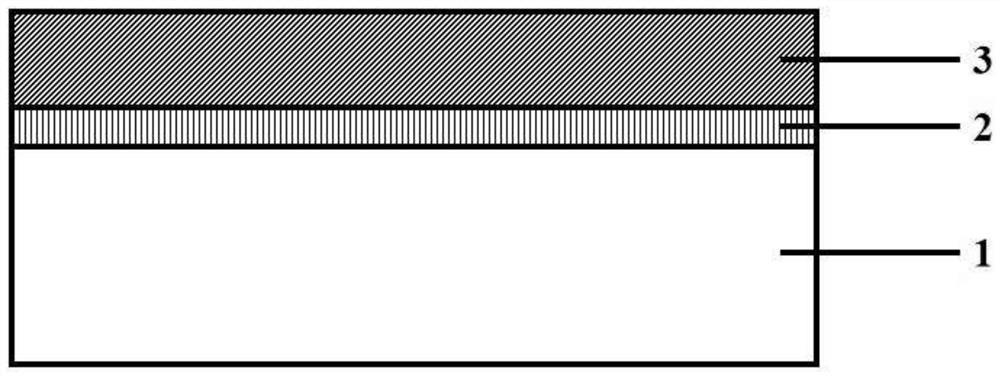

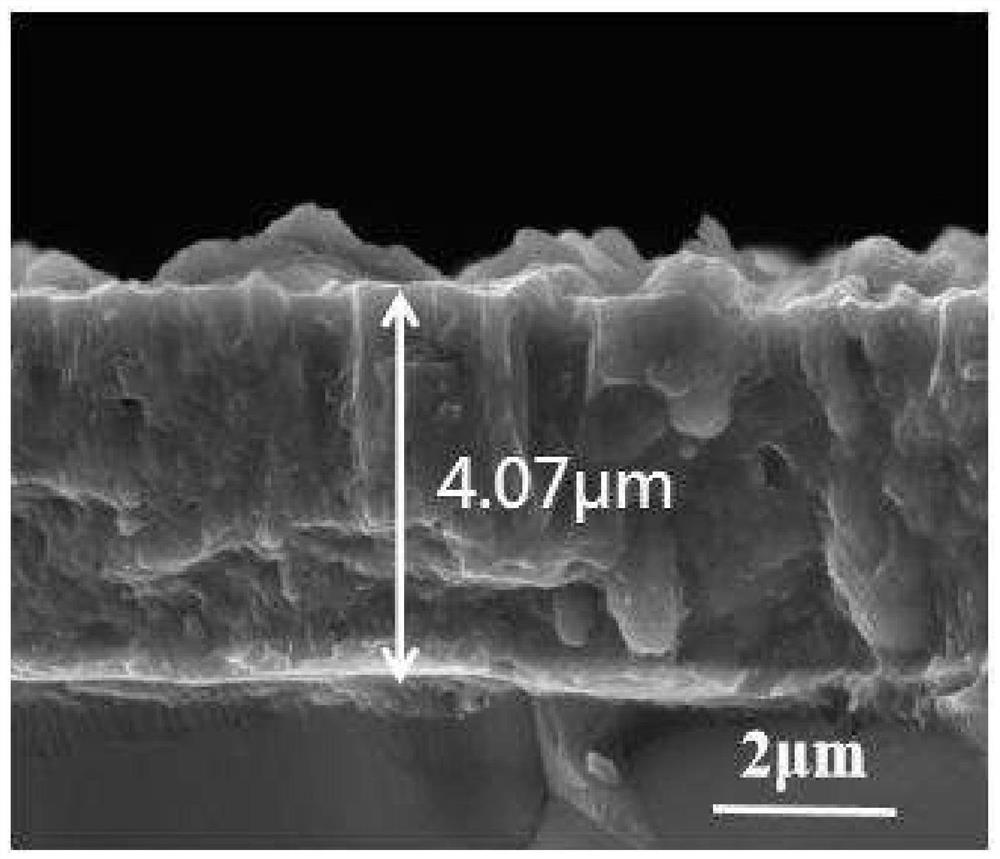

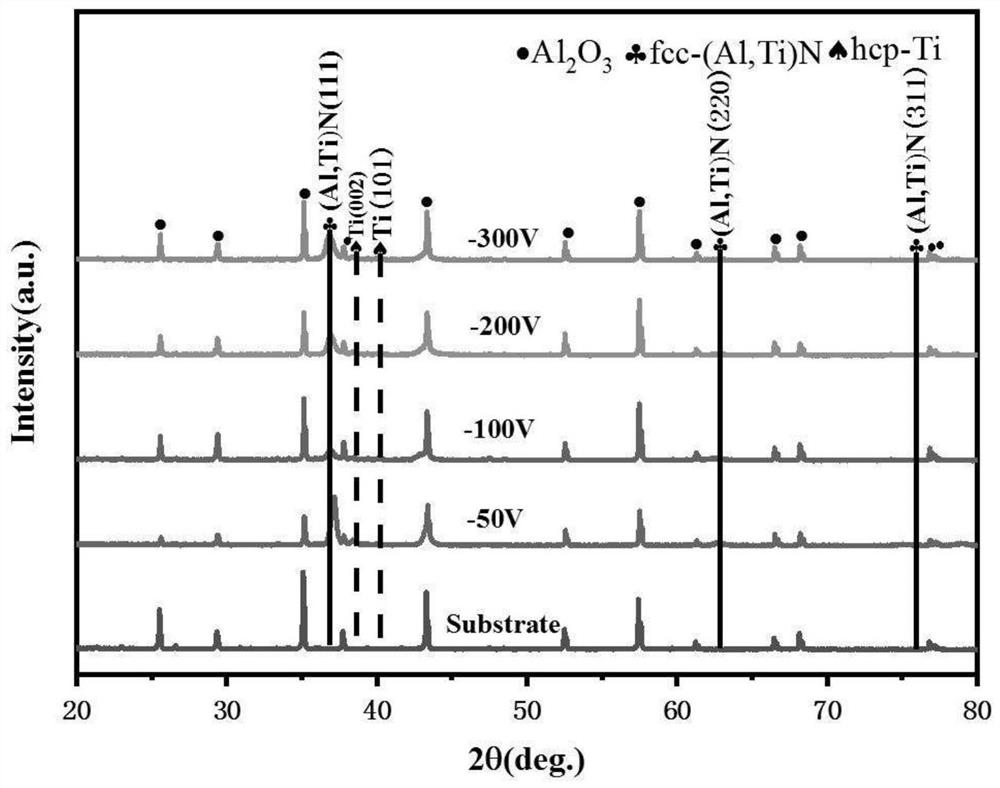

[0041] S3, preparation of pure metal Ti transition layer 2: Turn on the Ti circular arc target, set the Ti target arc current to 120A, deposition pressure to 3.5Pa, substrate negative bias voltage amplitude gradually reduced from 300V to 50V, duty cyc...

Embodiment 2

[0046] S1, substrate cleaning: place the alumina insulating substrate 1 in acetone, deionized water and ethanol in sequence for ultrasonic cleaning for 15 minutes each, and then dry it for later use.

[0047] S2, strong beam argon ion bombardment: place the aluminum oxide substrate on the substrate stage of vacuum ion plating, vacuumize, and the background vacuum reaches 5×10 -4 pa, the substrate temperature is heated to 300°C, argon gas is introduced to 100 sccm, the column arc shield is closed, the column arc Ti target is opened, and the auxiliary anode ion source is connected, the ion source current is 80-110A, and the substrate negative bias voltage amplitude is 300V , Argon ion etching cleaning time is 40min.

[0048] S3, preparation of pure metal Ti transition layer 2: Turn on the Ti circular arc target, set the Ti target arc current to 120A, deposition pressure to 3.5Pa, substrate negative bias voltage amplitude gradually reduced from 300V to 50V, duty cycle to 60%, obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com