Method for preparing three-dimensional optical waveguide and photonic device structure in transparent material

A technology of transparent materials and photonic devices, applied in the directions of optical waveguides, light guides, optical components, etc., can solve the problems of difficult to control the size of the mode field, large bending radius, limited change of the refractive index of the optical waveguide, etc. The effect of miniaturization and easy control of doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

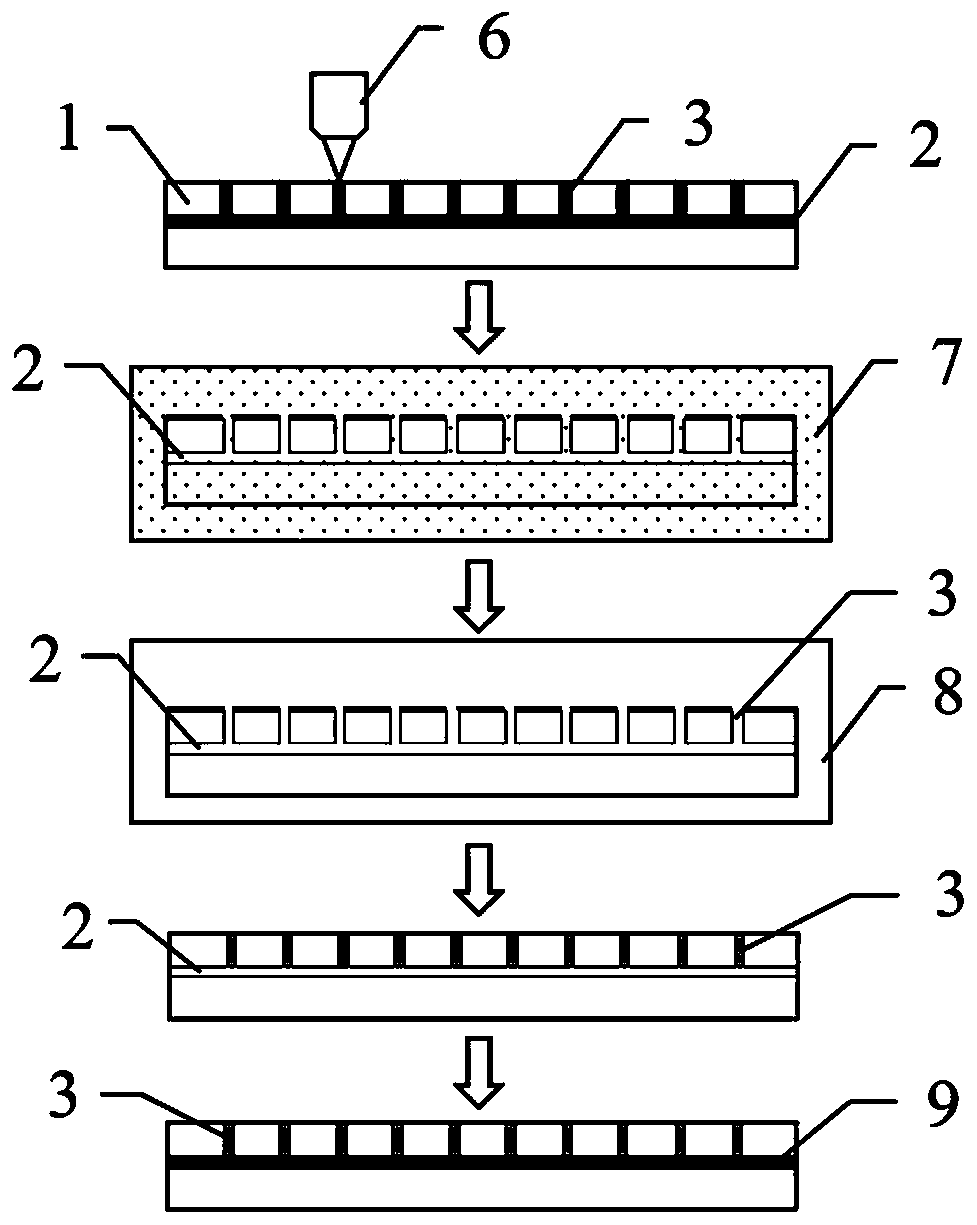

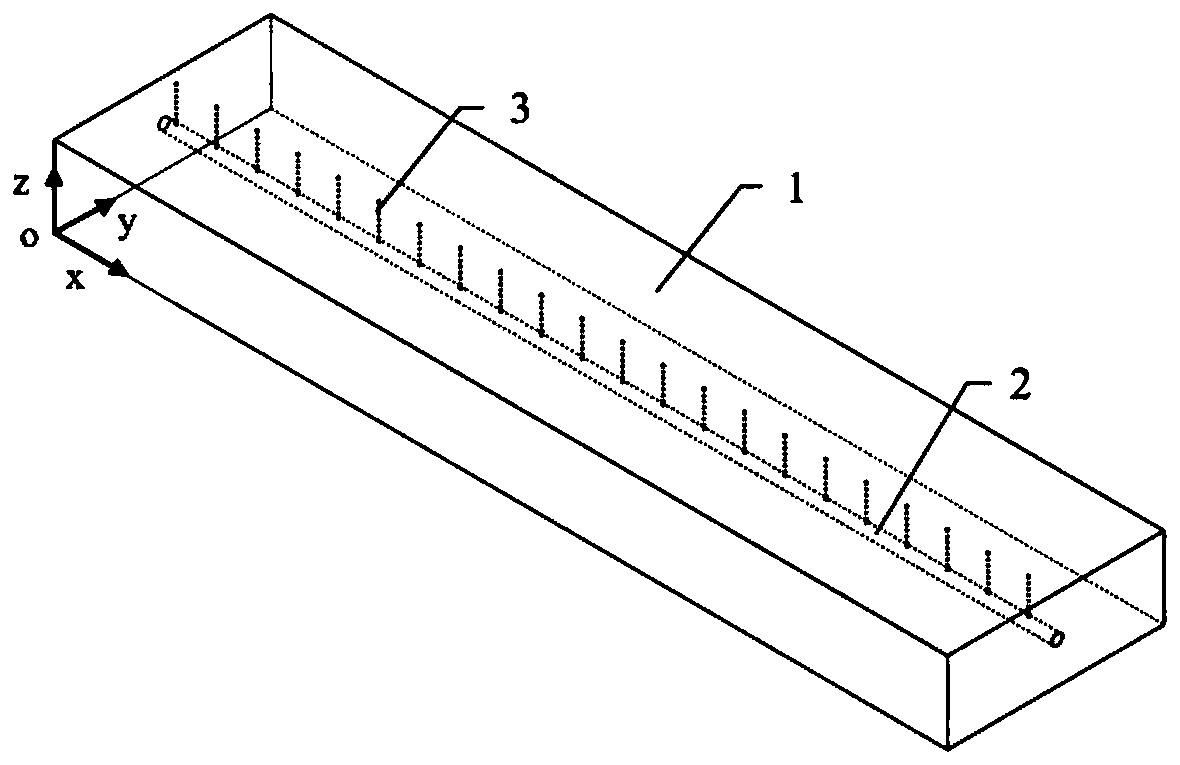

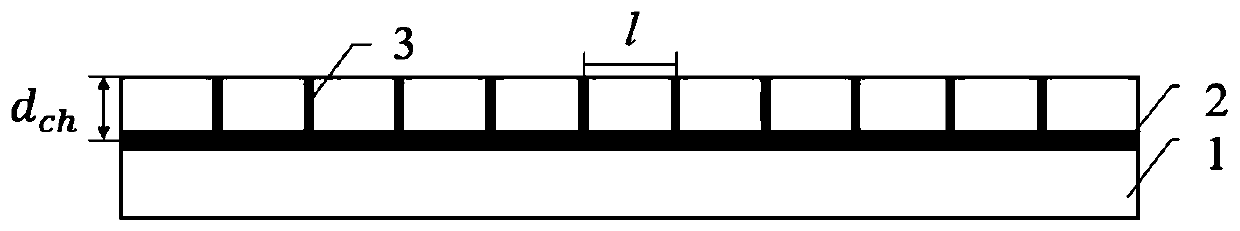

[0033] The present invention proposes a method for preparing a three-dimensional optical waveguide and a photonic device structure in a transparent material by using an ultrafast laser, which includes:

[0034] Step 1. Fix the transparent material sample on the three-dimensional movable processing platform, focus the ultrafast laser into the sample through the microscope objective lens, use the three-dimensional platform to drive the sample to move, and realize the spatial selective modification of the laser in the sample. Thus, the direct-write processing of the internal channel pattern of the sample is obtained. In order to ensure that microchannels with uniform and controllable diameters are obtained in the subsequent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com