Hydrogen storage container hydrogen storage well inner wall hydrogen blocking process

A technology for hydrogen storage container and gas storage well, which is applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of low tensile strength, limited application of underground gas storage wells, and small molecular structure, etc. The effect of preventing hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

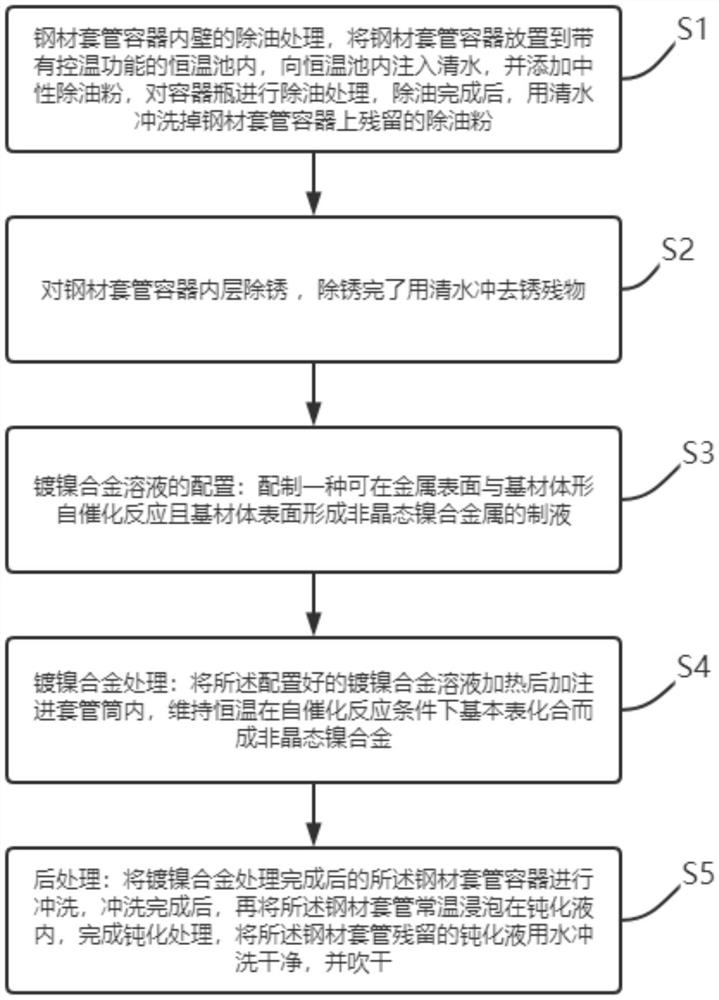

[0019] see figure 1 , the present invention provides a technical solution: a hydrogen storage container hydrogen gas storage well inner wall hydrogen resistance process, comprising the following steps:

[0020] Step 1. Degreasing treatment of hydrogen gas storage well steel cylinder and hydrogen storage container casing: place the hydrogen gas storage well steel cylinder and hydrogen storage container in a constant temperature pool with temperature control function, inject clean water into the constant temperature pool, and add degreasing Degreasing the steel cylinder of the hydrogen gas storage well and the hydrogen storage container. After the degreasing is completed, rinse off the degreasing powder remaining on the steel cylinder of the hydrogen gas storage well and the casing of the hydrogen storage container with clean water.

[0021] Step 2: Descaling and dedusting the hydrogen storage container and the surface of the hydrogen storage well facing the hydrogen.

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com