Ultrahigh pressure hydrogen storage tank

A storage tank, ultra-high pressure technology, applied in the direction of capping, closing the container tightly with a lid, application, etc., can solve the problems of tank leakage, low basic energy consumption, failure of hydrogen storage tank, etc., and achieve the reduction of temperature sensitivity, Effect of improving connection strength and improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

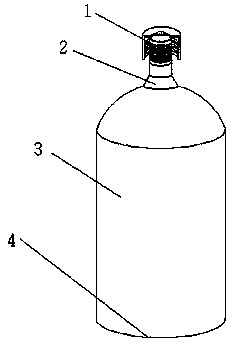

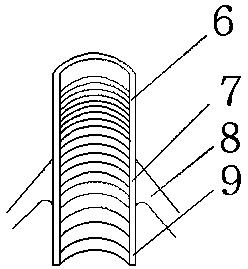

[0027] As shown in the accompanying drawings: an ultra-high pressure hydrogen storage tank, the tank body 3, the sealing cover 1 and the high-strength sealing nozzle 2, the high-strength sealing nozzle 2 is arranged on the tank body 3, and the sealing cover 1 is sealed with the high-strength sealing nozzle 2 Connection, the sealing cover 1 is provided with a gas discharge device or an inflating device, the sealing cover 1 is provided with a sealing gasket 11, and the two ends of the tank body 3 are integrally formed with a high-strength sealing nozzle 2, which avoids welding or other methods of connection. , it is convenient to improve the air tightness and service life of the tank body 3, prevent cracks and air leakage at the welding place, and facilitate the improvement of the safety of the storage tank; high-strength sealing nozzles 2 are arranged at both ends to facilitate the delivery of hydrogen to the inside and outside of the tank body 3, Gas delivery at one end and del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com