Flame-retardant silicone rubber material as well as preparation method and application thereof

A silicone rubber and rubber technology, applied in the field of materials, can solve the problems of detrimental physical and mechanical properties such as strength and rebound of silicone rubber materials, the inability of the system formulation to achieve the optimal ratio, and the unclear theoretical optimal ratio relationship. Achieve good physical and mechanical properties, good compatibility and dispersion, and solve the effect of single flame retardant element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

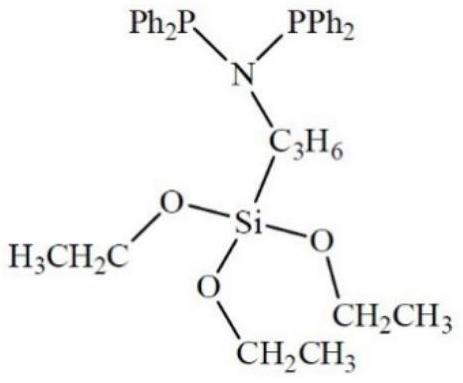

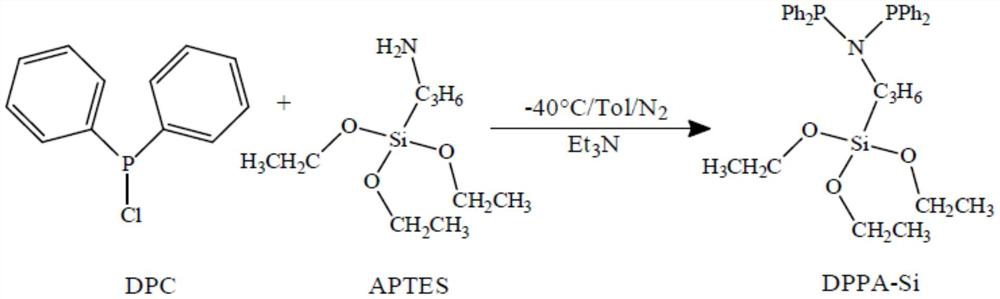

Method used

Image

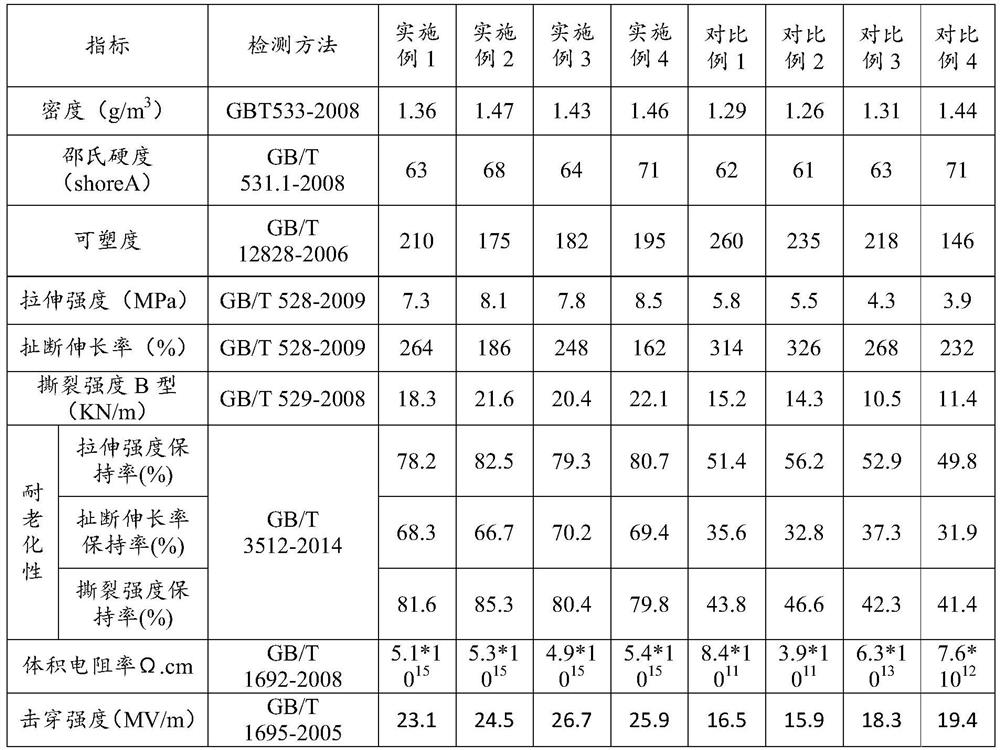

Examples

Embodiment 1

[0068] The flame retardant silicone rubber material in this example includes the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 35 parts of precipitated silica, 7 parts of dihydroxypolydimethylsiloxane, DPPA-Si3 30 parts of flame retardant, 1.0 parts of rosin, 25 parts of kaolin, and 2.0 parts of double pentasulfurizing agent. Wherein, the DPPA-Si ternary flame retardant includes the following raw materials in parts by weight: 4.0 g of γ-aminopropyltriethoxysilane, 4.2 g of triethylamine, 62.4 g of toluene, and 8.4 g of diphenylphosphine chloride.

[0069] In the formula of the flame-retardant silicone rubber material in this example, the molecular weight of methyl vinyl silicone rubber is 480,000, the mole fraction content of vinyl is 0.16%, and the volatile matter is ≤2.0%; SiO in precipitated silica 2 The mass content of ≥97%, CTAB specific surface area 170m 2 / g, DBP oil absorption value 2.6cm 3 / g, heating loss ≤ 8%; dihydroxy pol...

Embodiment 2

[0081] The flame-retardant silicone rubber material in this example includes the following raw materials by weight: 80 parts of methyl vinyl silicone rubber with a molecular weight of 500,000, 20 parts of methyl vinyl silicone rubber with a molecular weight of 650,000, and 45 parts of precipitated white carbon black , 9.0 parts of dimethyldimethoxysilane, 45 parts of DPPA-Si ternary flame retardant, 0.5 parts of solid coumarone, 1.0 parts of microcrystalline wax, 30 parts of magnesium silicate, and 5.0 parts of BIPB-40B curing agent. The DPPA-Si ternary flame retardant includes the following raw materials: 6.0g γ-aminopropyltriethoxysilane, 6.3g triethylamine, 94g toluene, and 13g diphenylphosphine chloride.

[0082] In the formula of flame retardant silicone rubber material, the vinyl mole fraction content of methyl vinyl silicone rubber with a molecular weight of 500,000 is 0.24%, and the vinyl mole fraction content of methyl vinyl silicone rubber with a molecular weight of 6...

Embodiment 3

[0092]The flame retardant silicone rubber material in this example includes the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 40 parts of fumed silica, 4.0 parts of dihydroxy polydimethylsiloxane, 4 parts of methyl phenyl 5.0 parts of diethoxysilane, 35 parts of DPPA-Si ternary flame retardant, 2.0 parts of microcrystalline wax, 25 parts of kaolin, 20 parts of calcium carbonate, 1.5 parts of bis-pentasulfurizing agent, and 3.0 parts of BIPB-40B curing agent. The DPPA-Si ternary flame retardant includes the following raw materials: 4.7g of γ-aminopropyltriethoxysilane, 5.0g of triethylamine, 73g of toluene, and 10g of diphenylphosphine chloride.

[0093] In the formula of flame retardant silicone rubber material, the molecular weight of methyl vinyl silicone rubber is 480,000, the vinyl mole fraction content is 0.16%, and the volatile matter is ≤2.0%; SiO in fumed silica 2 Mass content ≥ 97%, CTAB specific surface area 190m 2 / g, DBP oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com