Battery diaphragm, coating process and coating system thereof and battery

A battery separator and coating process technology, used in fuel cells, battery pack components, and devices for coating liquids on surfaces, etc., can solve the problems of heat resistance, moisture, porosity, adhesion and consistency. It is expected that the safety performance and electrochemical performance cannot be taken into account at the same time, and the internal resistance of the diaphragm increases, so as to achieve the effect of reducing unstable factors, improving porosity and consistency, and improving electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The polyolefin film is an ultra-high molecular weight PE base film with a molecular weight of 2 million, and the coating is a ceramic coating, and the ceramic coating is coated on one surface of the PE base film. The ceramic slurry includes water, thickener, ceramic particles, adhesive, wetting agent, and has a solid content of 32%.

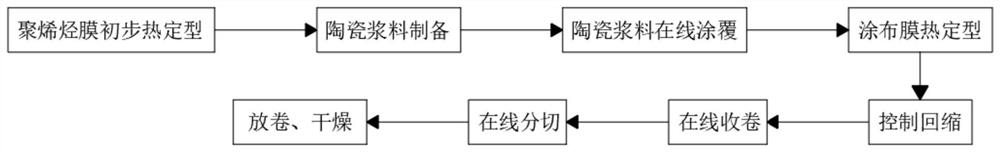

[0053] Such as figure 1 As shown, the main process flow of this embodiment is: preliminary heat setting of polyolefin film—preparation of ceramic slurry—online coating of ceramic slurry—heat setting of coating film—control shrinkage—online winding— —Online slitting—unwinding and drying.

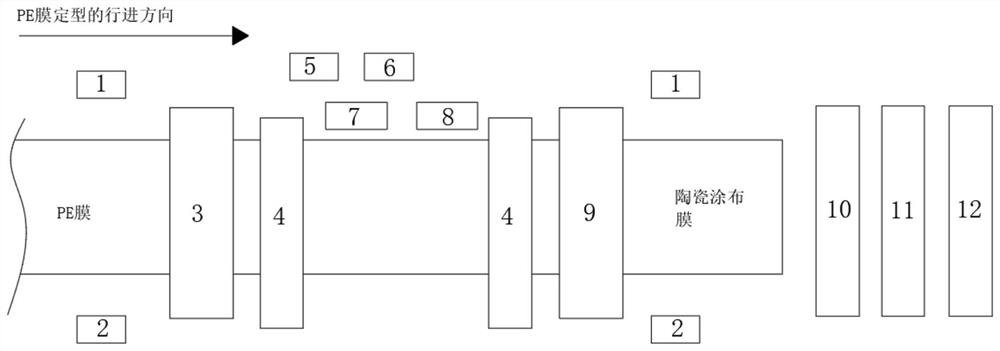

[0054] Such as figure 2 As shown, the coating device of this embodiment includes a defect meter 1, a thickness gauge 2, a preliminary heat setting oven 3, an adsorption roller 4, a filter 5, a transfer tank 6, a coating device 7, a shrinkage control device 8, a coating Heat setting oven 9, online winding device 10, online slitting device 11, unwinding...

Embodiment 2

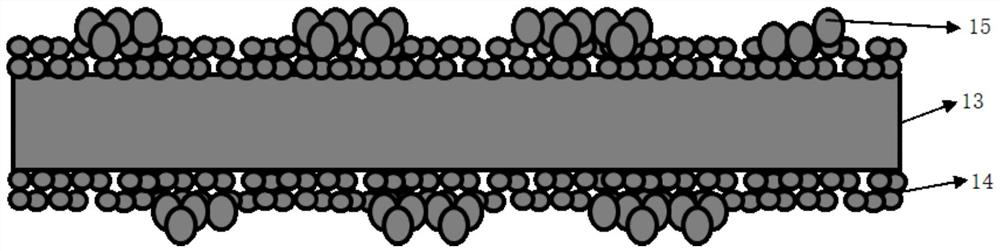

[0059] This embodiment is a composite coating battery diaphragm, such as image 3 As shown, the composite coating battery separator includes a polyolefin substrate 13, a heat-resistant coating 14 coated on both sides of the polyolefin substrate 13, and a spray coating 15 sprayed on the heat-resistant coating 14. The heat-resistant coating Layer 14 is a ceramic coating.

[0060] Such as Figure 4 As shown, the main process flow of this embodiment is: preliminary heat setting of polyolefin film—preparation of ceramic slurry—online coating of ceramic slurry—online spray coating—heat setting of coating film—controlling shrinkage - On-line winding - On-line slitting - Unwinding and drying.

[0061] When the polyolefin film is not completely heat-set, the coating of the ceramic coating is carried out, and when the ceramic coating is not completely dry, the spray coating is performed.

[0062] Among them, the ceramic coating slurry with a solid content of 38.6% is configured, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com