Manufacturing method of high-density interconnected printed circuit board

A printed circuit board, high-density interconnection technology, applied in printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of uneven heat dissipation, unsuitable power, and high cost, improve thermal conductivity, and facilitate disassembly and maintenance. , the effect of good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment prepares a thermally conductive adhesive, and the specific implementation process is as follows:

[0034] Step A1: Take 1L of di-p-toluene sulfide solution and 15g of aluminum trichloride powder, and stir in a high-speed stirrer at a stirring rate of 1500rmp to form a suspension, and then put magnetons into the suspension to set Stirring rate is 300rmp, in the state of stirring, pass through the catheter into the suspension to react with chloroform, the amount of chloromethane introduced is 0.1m 3 , the feeding time of monochloromethane is 2h, and then the reaction solution is ventilated in a fume hood and placed overnight, so that the aluminum chloride in the reaction solution is sublimated, and the intermediate reaction solution is obtained. Under the catalysis of aluminum chloride, Friedel-Crafts reaction between di-p-toluene sulfide and methylene chloride;

[0035] The di-p-toluene sulfide solution is prepared by uniformly mixing di-p-toluene sulfid...

Embodiment 2

[0041] This embodiment prepares a thermally conductive adhesive, the specific implementation process is the same as that of Example 1, only the reaction process parameters are adjusted, as follows:

[0042] In step A2, the reaction temperature of the intermediate reaction liquid and potassium permanganate is raised to 75°C;

[0043] In step A3, the reaction time of p-phenylenediamine, EDA and the target reaction solution is 30 hours, and then the temperature is raised to 35°C;

[0044] In step A5, the dosage ratio of the modified nano-alumina and the adhesive is 6.5g:500mL.

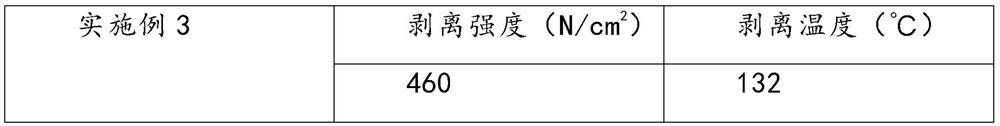

Embodiment 3

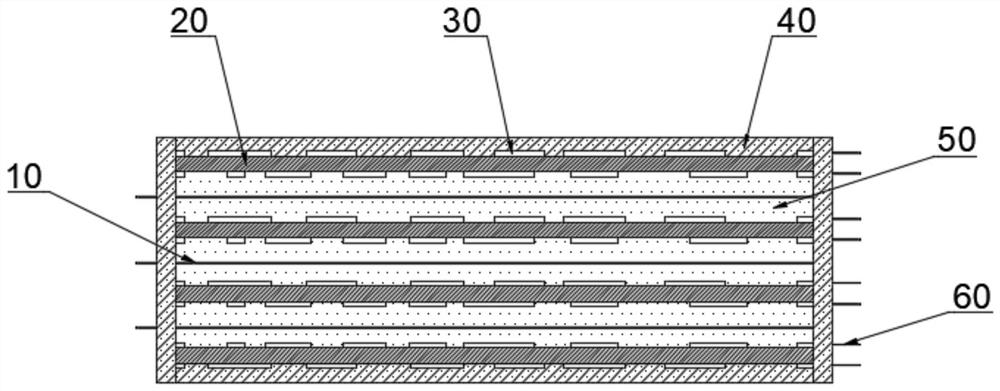

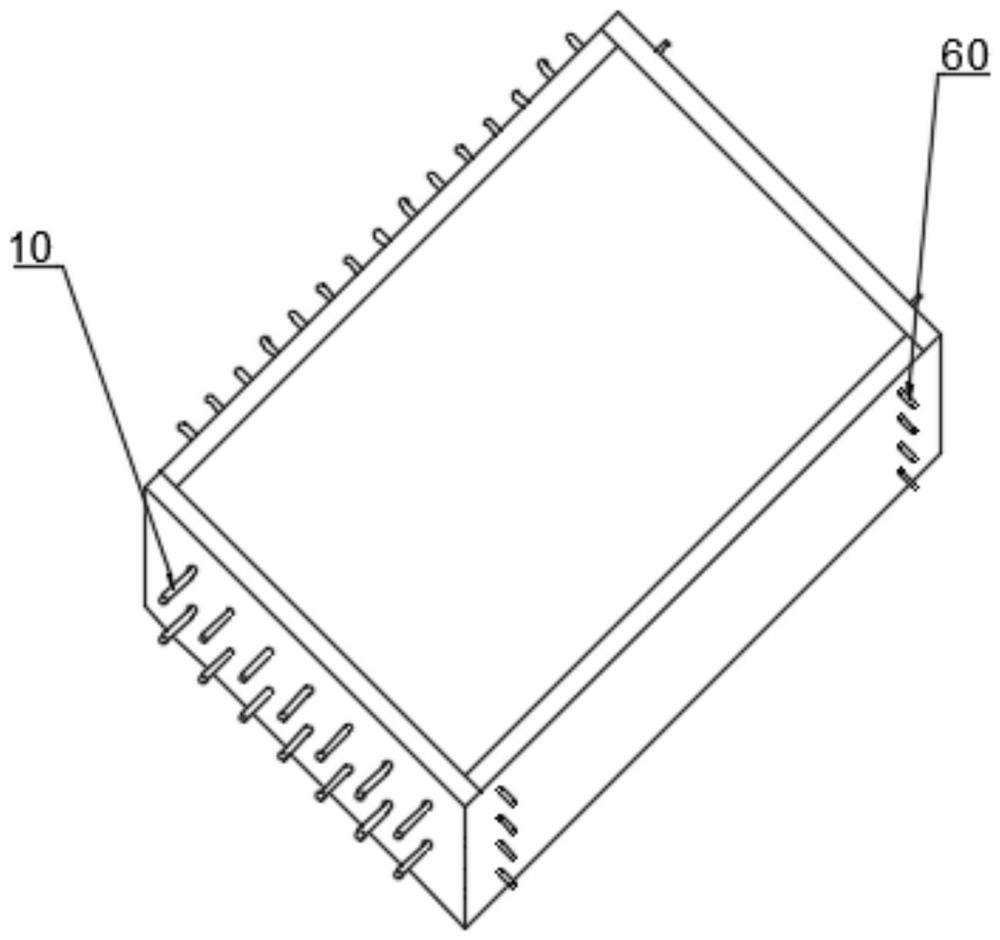

[0046] This embodiment makes a high-density interconnection printed circuit board, please refer to Figure 1-2 As shown, the specific production method is as follows:

[0047] Step S1: Take the circuit substrate 20, which is a common phenolic resin-based thermosetting circuit substrate 20 in the market, clean both sides of the circuit substrate 20, apply adhesive glue on both sides of the circuit substrate 20, and apply adhesive on both sides of the circuit substrate 20. Glue the copper sheet 30, the copper sheet 30 is a commercially available circuit copper sheet 30, and the thickness is selected according to the actual application. In this embodiment, an electrical copper foil with a thickness of 0.5 mm is used to degrease, etch, level and clean the copper sheet 30 , to get the composite veneer;

[0048] Step S2: Coating a layer of heat-conducting adhesive on both sides of the composite veneer, trimming and leveling the applied heat-conducting adhesive to form a heat-conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com