High-power power transformer

A high-power power supply and transformer technology, applied in transformer/inductor cooling, transformer/reactor installation/support/suspension, transformer/inductor coil/winding/connection, etc., can solve the problem of no auxiliary stability and damping, utilization Low, slow heat dissipation and other issues, to achieve stable and long-term operation, increase the contact surface area, and ensure the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

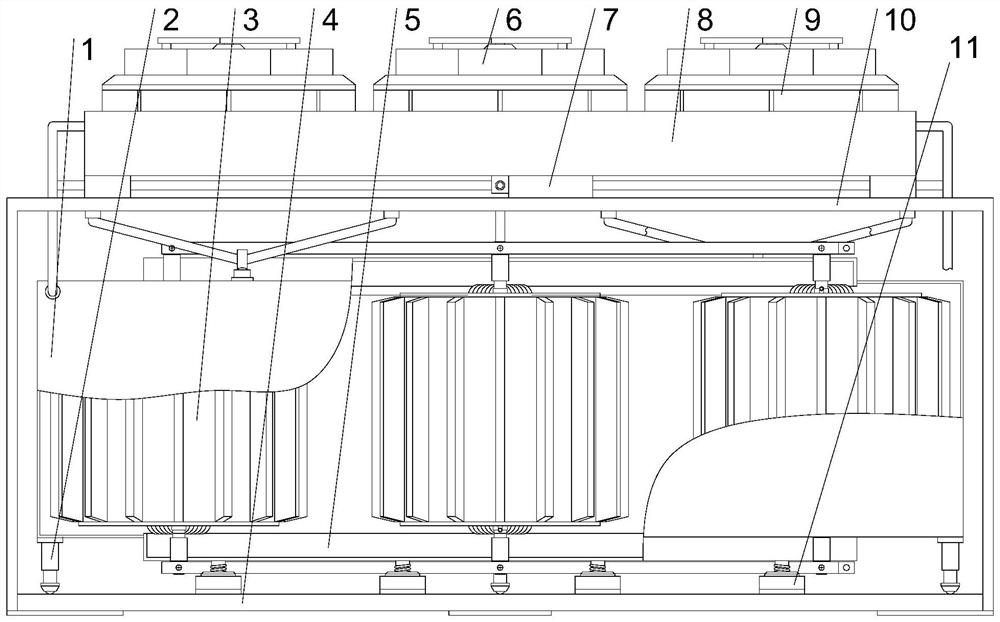

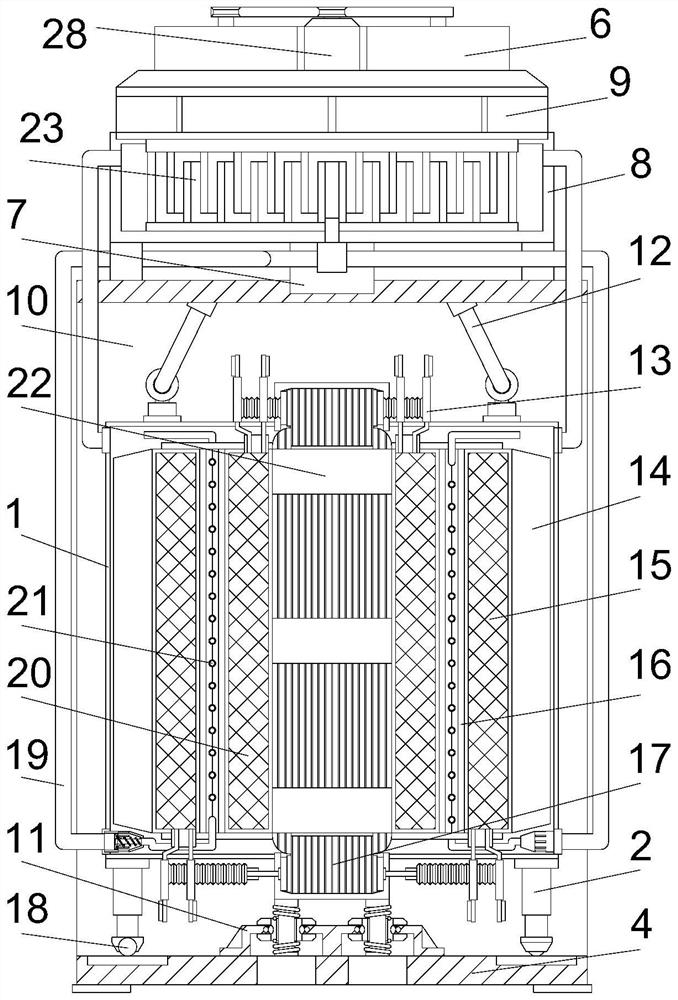

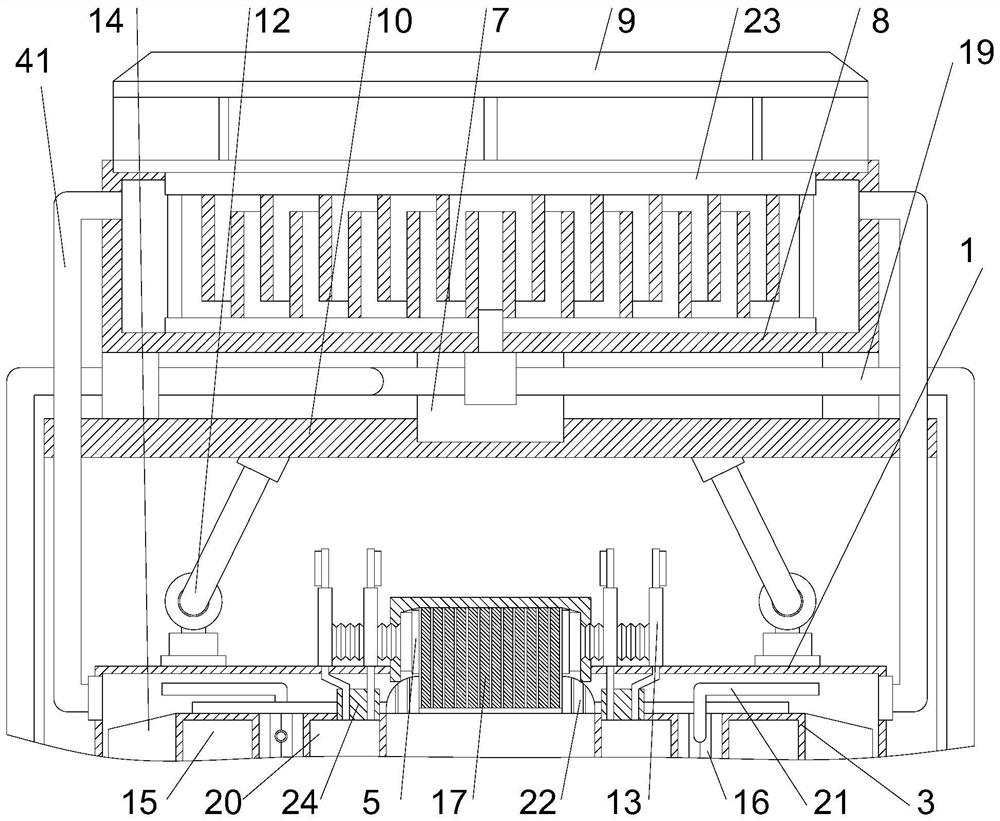

[0027] Such as Figure 1-Figure 8 As shown, a high-power power transformer according to the present invention includes a casing 1, a gantry 10, an air-cooled module, a water tank 8, a shock absorbing mechanism, a water distributor and a winding structure, and the bottom of the gantry 10 is fixedly installed There is a bottom plate 4, a steel cable 12 is fixedly installed on the inner wall of the top of the bottom plate 4, a ring frame is installed on the outer middle part of the steel cable 12, a shell 1 is fixedly installed on the bottom end of the ring frame, a water tank 8 is fixedly installed on the top of the gantry frame 10, and the water tank 8. A heat exchange frame 23 is fixedly installed in the middle part of the inner side. An air-coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com