Positive electrode material of lithium-sulfur battery composite electrode and preparation method and application of positive electrode material

A technology of positive electrode material and composite electrode, which is applied in the field of composite electrode positive electrode material and its preparation, can solve the problems of increasing battery impedance, process difficulties, etc., and achieves the improvement of wettability, strong chemical adsorption capacity, good cycle performance and rate performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

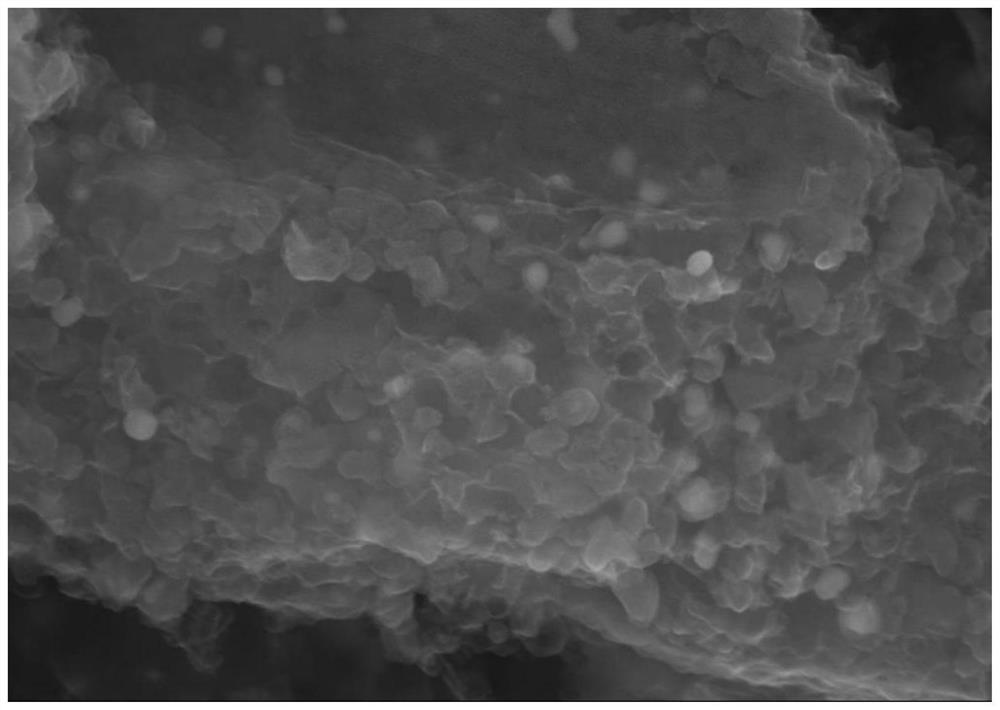

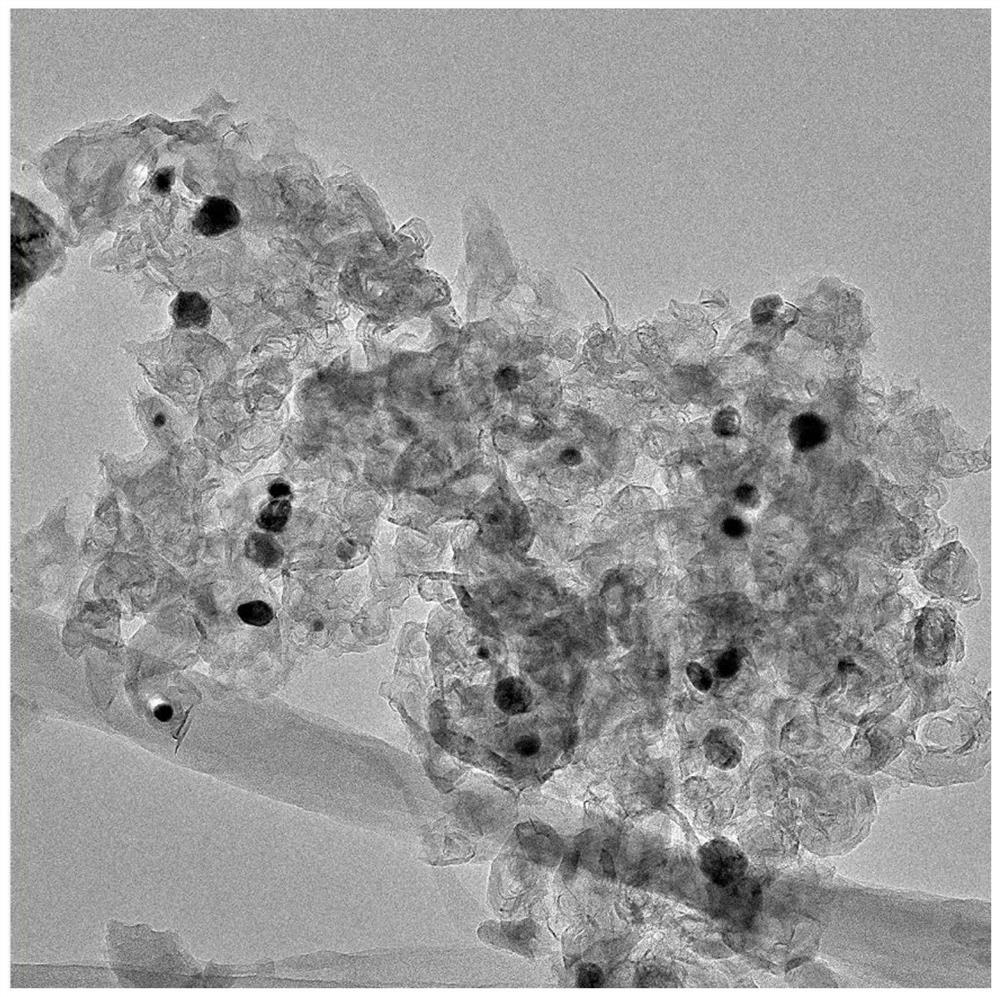

[0065] This embodiment provides a method for preparing a positive electrode material. The preparation method specifically includes the following steps:

[0066] (1) Prepare a mixed metal salt solution of 20 mmol / L, dissolve 0.1428 g of cobalt chloride hexahydrate and 0.162 g of ferric chloride hexahydrate in 30 mL of deionized water, stir at room temperature until the solution is clear, and obtain an orange-yellow solution;

[0067] (2) Cut the transfer filter paper with a thickness of 1cm into a size of 16×16cm, and soak it in the above-mentioned mixed solution for 2 hours;

[0068] (3) Place the transfer filter paper soaked in the metal salt solution obtained in step (2) in a blast drying oven at 60°C for 12 hours;

[0069] (4) High-temperature calcination, in an atmosphere with a volume ratio of argon and hydrogen of 9:1, first raise the temperature from 25°C to 300°C at a heating rate of 2°C / min, and keep it at 300°C for 1 hour; then heat it at 1°C The temperature was rai...

Embodiment 2

[0071] This embodiment provides a method for preparing a positive electrode material. The preparation method specifically includes the following steps:

[0072] (1) Prepare a mixed metal salt solution of 20 mmol / L, dissolve 0.1428 g of cobalt chloride hexahydrate and 0.162 g of ferric chloride hexahydrate in 30 mL of deionized water, stir at room temperature until the solution is clear, and obtain an orange-yellow solution;

[0073] (2) Cut the transfer filter paper with a thickness of 1cm into a size of 16×16cm, and soak it in the above-mentioned mixed solution for 2 hours;

[0074] (3) Place the transfer filter paper soaked in the metal salt solution obtained in step (2) in a blast drying oven at 55°C for 12 hours;

[0075] (4) High-temperature calcination, in an atmosphere with a volume ratio of argon and hydrogen of 9:1, the temperature is first raised from 30°C to 250°C at a heating rate of 1°C / min, and kept at 250°C for 1.5h; The temperature was raised from 250 °C to 75...

Embodiment 3

[0077] This embodiment provides a method for preparing a positive electrode material. The preparation method specifically includes the following steps:

[0078] (1) Prepare a mixed metal salt solution of 20 mmol / L, dissolve 0.1428 g of cobalt chloride hexahydrate and 0.162 g of ferric chloride hexahydrate in 30 mL of deionized water, stir at room temperature until the solution is clear, and obtain an orange-yellow solution;

[0079] (2) Cut the transfer filter paper with a thickness of 1cm into a size of 16×16cm, and soak it in the above-mentioned mixed solution for 2 hours;

[0080] (3) Place the transfer filter paper soaked in the metal salt solution obtained in step (2) in a blast drying oven at 62°C for 12 hours;

[0081] (4) High-temperature calcination, in an atmosphere with a volume ratio of argon to hydrogen of 8:1, first raise the temperature from 35°C to 350°C at a heating rate of 2°C / min, and keep it at 300°C for 2 hours; then heat it at 1.5°C The temperature was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com