Zinc oxide piezoresistor preparation method based on chemical deposition method

A varistor and zinc oxide technology, applied in varistors, varistor cores, resistance manufacturing, etc., can solve the problems of low electrical performance of ZnO varistors and inability to apply UHV arresters, etc., and achieve easy Effects of low cost control, reduction of impurity ions, and improvement of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

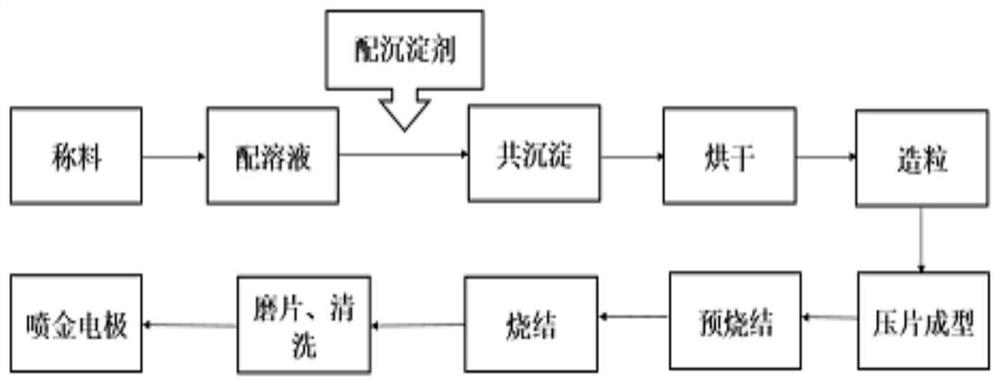

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a zinc oxide varistor based on a chemical precipitation method, comprising the following steps:

[0034] (1) Weighing raw materials: use an electronic balance with an accuracy of 0.001g to weigh the various components of the raw materials, specifically: 86.36g ZnO, 11.42g Bi(NO 3 ) 3 ·5H 2 O, 0.6g Co(NO 3 ) 2 ·6H 2 O, 0.02g Cr(NO 3 ) 3 9H 2O, 0.49gMn((NO 3 )·4H 2 O, 0.36g Ni((NO 3 ) 2 ·6H 2 O and 0.75 g SbCl 3 ;

[0035] (2) chemical precipitation mixing: keep the total volume of the reaction solution at 800ml constant, dissolve the raw materials weighed in the step (1) with 533.3ml ethylene glycol, form a mixed solution, stir continuously with a magnetic stirrer, and heat simultaneously to 90°C; then dissolve 5g NaOH with 266.6ml of deionized water, and drop the NaOH solution into the mixed solution at a certain rate until the pH in the mixed solution is maintained at 10, react for 2 hours and carry out precipitation filtration, and...

Embodiment 2

[0043] A method for preparing a zinc oxide varistor based on a chemical precipitation method, comprising the following steps:

[0044] (1) Weighing raw materials: use an electronic balance with an accuracy of 0.001g to weigh the various components of the raw materials, specifically: 86.36g ZnO, 11.42g Bi(NO 3 ) 3 5H2O, 0.6g Co(NO 3 ) 2 ·6H 2 O, 0.02g Cr(NO 3 ) 3 9H 2 O, 0.49gMn((NO 3 )·4H 2 O, 0.36g Ni((NO 3 ) 2 ·6H 2 O and 0.75 g SbCl 3 ;

[0045] (2) chemical precipitation mixing: keep the total volume of the reaction solution at 800ml constant, dissolve the raw materials weighed in the step (1) with 524.1ml ethylene glycol, form a mixed solution, stir continuously with a magnetic stirrer, and heat simultaneously to 80°C; then dissolve 5g NaOH with 275.9ml of deionized water, and drop the NaOH solution into the mixed solution at a certain rate until the pH in the mixed solution is maintained at 9, react for 2 hours and carry out precipitation filtration, and the...

Embodiment 3

[0053] (1) Weighing raw materials: use an electronic balance with an accuracy of 0.001g to weigh the various components of the raw materials, specifically: 86.36g ZnO, 11.42g Bi(NO 3 ) 3 5H2O, 0.6g Co(NO 3 ) 2 ·6H 2 O, 0.02g Cr(NO 3 ) 3 9H 2 O, 0.49gMn((NO 3 )·4H 2 O, 0.36g Ni((NO 3 ) 2 ·6H 2 O and 0.75 g SbCl 3 ;

[0054] (2) chemical precipitation mixing: keep the total volume of the reaction solution at 800ml constant, dissolve the raw materials weighed in the step (1) with 541.9ml ethylene glycol, form a mixed solution, stir continuously with a magnetic stirrer, and heat simultaneously to 85°C; then dissolve 5g NaOH with 258.1ml deionized water, and drop the NaOH solution into the mixed solution at a certain rate until the pH in the mixed solution is maintained at 9.5, and carry out precipitation filtration after 2 hours of reaction, and then Wash the sediment several times with deionized water to obtain a mixed slurry for later use;

[0055] (3) Drying and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com