Curved surface conformal 4D printing method of thin-wall heterostructure and heterostructure

A technology of heterogeneous structure and curved surface, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., can solve the problems of inability to realize surface conformal electromagnetic, electronic device manufacturing, limited forming area, and difficult processing, etc. The effect of difficulty, low cost and high relative forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

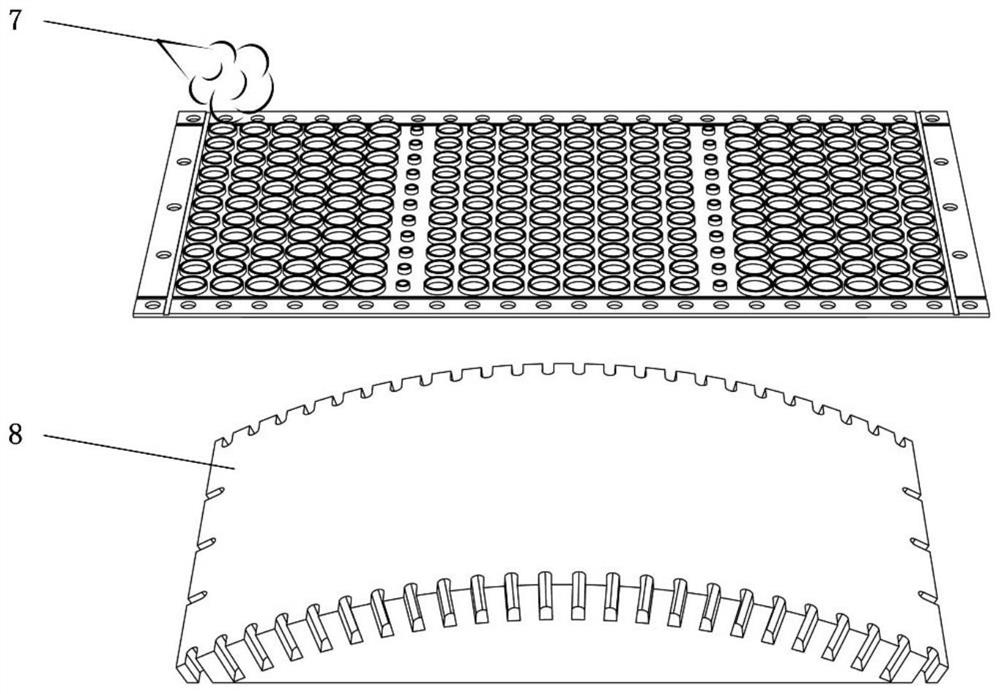

[0038] In embodiment 1 will figure 1 The arcuate surface heterogeneous functional structure shown is unfolded into a rectangular temporary planar structure, and a positioning auxiliary edge 9 structure is added.

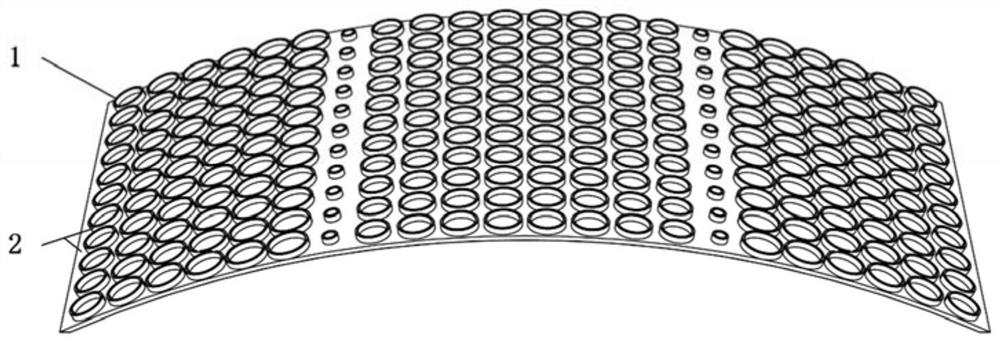

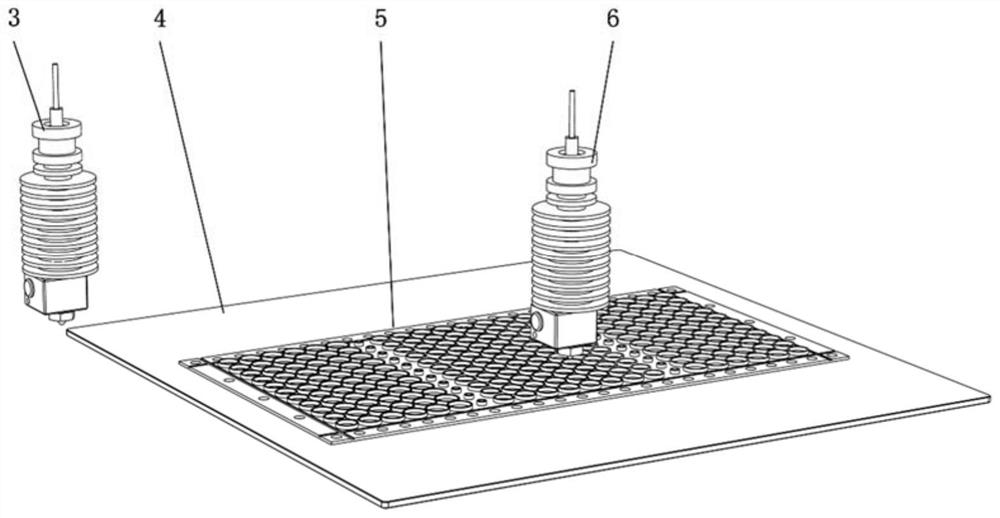

[0039] Such as figure 1 As shown, the heterogeneous functional structure in Example 1 is composed of several conductive resonant rings 1 and a dielectric substrate 2, and its curved surface is very difficult to manufacture. In order to reduce the difficulty of direct forming the heterogeneous functional structure of the target surface, the computer-aided design will figure 1 The 3D model of the heterogeneous functional structure of the surface shown is divided and unfolded as figure 2 In the three-dimensional model of the temporary planar structure 5 shown, the positioning auxiliary edge 9 is added, and then planar manufacturing and curved surface conformality can be performed, which can avoid the problem of curved surface manufacturing of heterogeneous structures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com