Nitrogen-doped porous carbon granular material for adsorbing CO2 and preparation method of nitrogen-doped porous carbon granular material

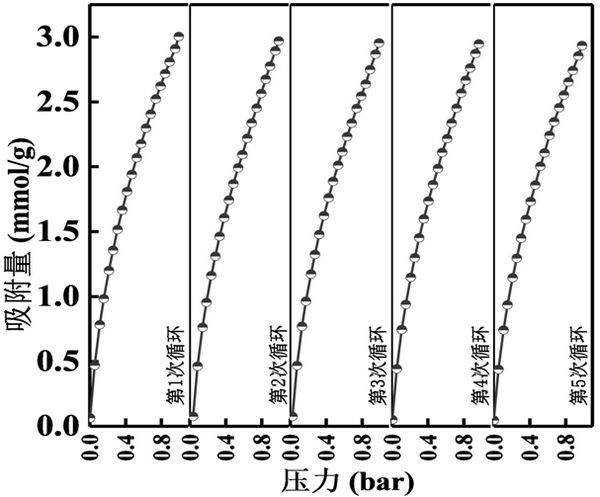

A granular material and porous carbon technology, which is applied in the field of nitrogen-doped porous carbon granular materials and its preparation, can solve problems affecting the application of porous carbon, achieve ideal CO2 adsorption stability, good CO2 adsorption capacity, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

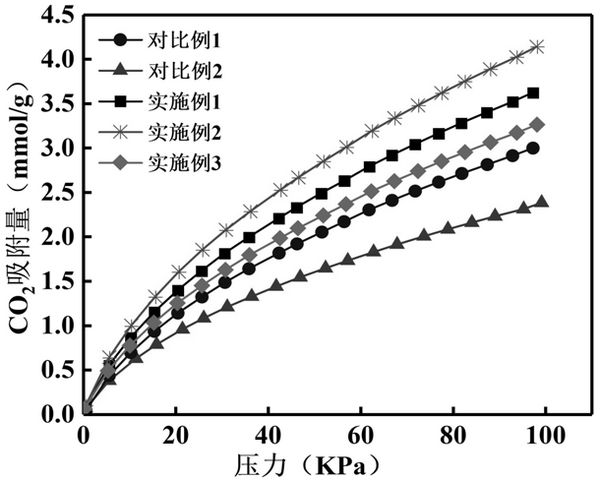

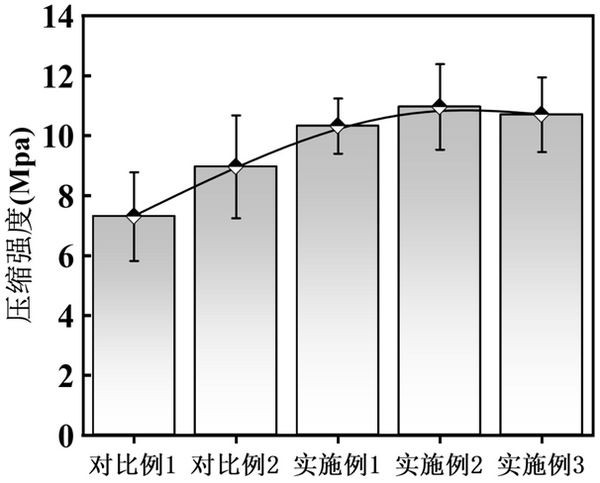

[0030] Preparation of nitrogen-doped porous carbon materials doped with 25% microalgae

[0031] Preparation of nitrogen-doped porous carbon materials based on poplar wood chips based on in situ synthesis, specifically:

[0032] Step 1: Pretreat poplar wood chips and microalgae, wash poplar wood chips repeatedly with water, and dry in a blast drying oven at 105°C for 24 hours, crush the dried poplar wood chips, and sieve to The size of 300-500μm is ready for use; the microalgae are dried in a blast drying oven at 45°C for 24h;

[0033] Step 2, take pretreated 10g poplar sawdust and 2.5g microalgae, soak in 50mL deionized water, stir magnetically at a speed of 200rpm for 24h, then place them in an oven for drying, and place the dried mixture in a tube In a type furnace, under a nitrogen atmosphere, the heating rate is 10°C / min, the temperature is raised to 600°C, and the temperature is kept at a constant temperature for 1 hour for pyrolysis and carbonization; after cooling to 2...

Embodiment 2

[0037] Preparation of nitrogen-doped porous carbon materials doped with 50% microalgae

[0038] Preparation of nitrogen-doped porous carbon materials based on poplar wood chips based on in situ synthesis, specifically:

[0039] Step 1, with embodiment 1;

[0040]Step 2, take spare 10g of poplar wood chips and 5g of microalgae, soak them in 50mL of deionized water, stir magnetically at a speed of 200rpm for 24h, then place them in an oven for drying, and place the dried mixture in a tube furnace , under a nitrogen atmosphere at a heating rate of 10°C / min, the temperature was raised to 600°C, and kept at a constant temperature for 1 hour for pyrolysis and carbonization; after cooling to 20-25°C, the product was repeatedly washed with deionized water and dried at 110°C , to obtain carbonized products;

[0041] Step 3, weigh the carbonized product and KOH at a mass ratio of 1:2, soak in 100mL deionized water, stir magnetically at a speed of 200rpm for 24h, and then place it in a...

Embodiment 3

[0044] Preparation of nitrogen-doped porous carbon materials doped with 200% microalgae

[0045] Preparation of nitrogen-doped porous carbon materials based on poplar wood chips based on in situ synthesis, specifically:

[0046] Step 1, with embodiment 1;

[0047] Step 2, take spare 10g of poplar wood chips and 20g of microalgae, soak them in 50mL of deionized water, stir magnetically at a speed of 200rpm for 24h, then place them in an oven for drying, and place the dried mixture in a tube furnace , under a nitrogen atmosphere at a heating rate of 10°C / min, the temperature was raised to 600°C, and kept at a constant temperature for 1 hour for pyrolysis and carbonization; after cooling to 20-25°C, the product was repeatedly washed with deionized water and dried at 110°C , to obtain carbonized products;

[0048] Step 3, weigh the carbonized product and KOH at a mass ratio of 1:2, soak in 100mL deionized water, stir magnetically at a speed of 200rpm for 24h, and then place it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com