Pre-oxidized ternary precursor for positive electrode material and preparation method of pre-oxidized ternary precursor

A technology for pre-oxidizing ternary and cathode materials, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve problems such as low metal content, and achieve the effect of increasing total metal content, improving cycle performance, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

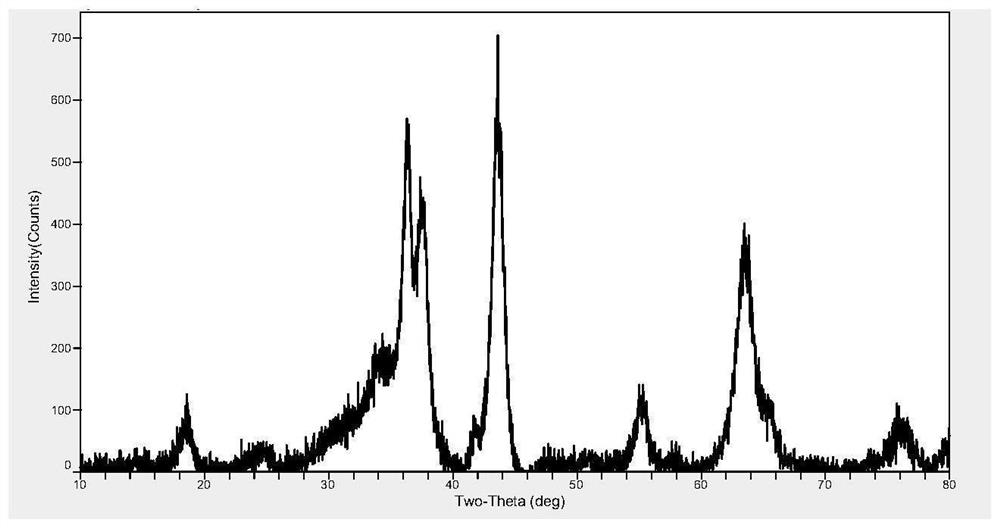

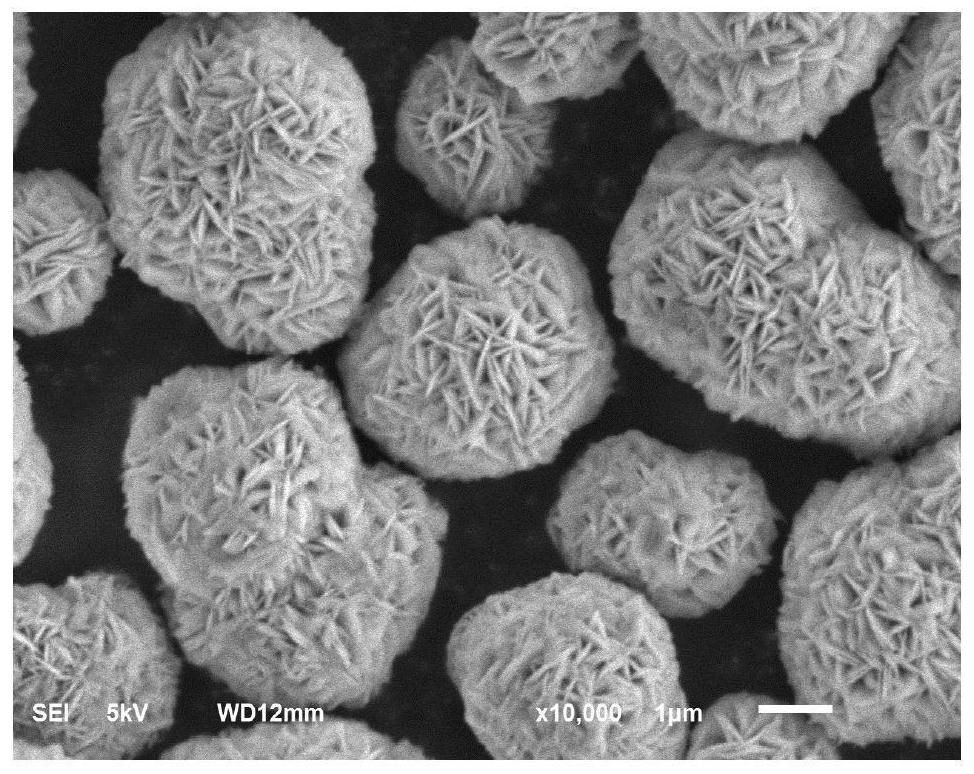

[0034] Example 1: A pre-oxidized ternary precursor for positive electrode materials and its preparation method

[0035] (1) Add 2 mol / L nickel-cobalt-manganese mixed sulfate solution and 2 mol / L ammonia solution in parallel flow at a constant speed. The ammonia solution contains tetraethylammonium hydroxide with a mass fraction of 1%, and at the same time Supply 8 mol / L sodium hydroxide solution to control the pH value of the process to be 11.5-12.0; nitrogen protection during the reaction, stirring speed at 500 rpm and reaction device temperature at about 50°C, control the reaction time to obtain D 50 Ni with 6.2µm and SPAN of 0.7 2+ 0.65 co 2+ 0.1 mn 2+ 0.25 (OH) 2 ;

[0036] (2) Aging the product obtained in step (1) for 2 hours, centrifuging and washing with water 2-3 times;

[0037] (3) Put the product of step (2) into a hot air circulation drying oven, and calcine at a low temperature of 95°C for 2 hours to obtain a low-temperature calcined product;

[0038] (4)...

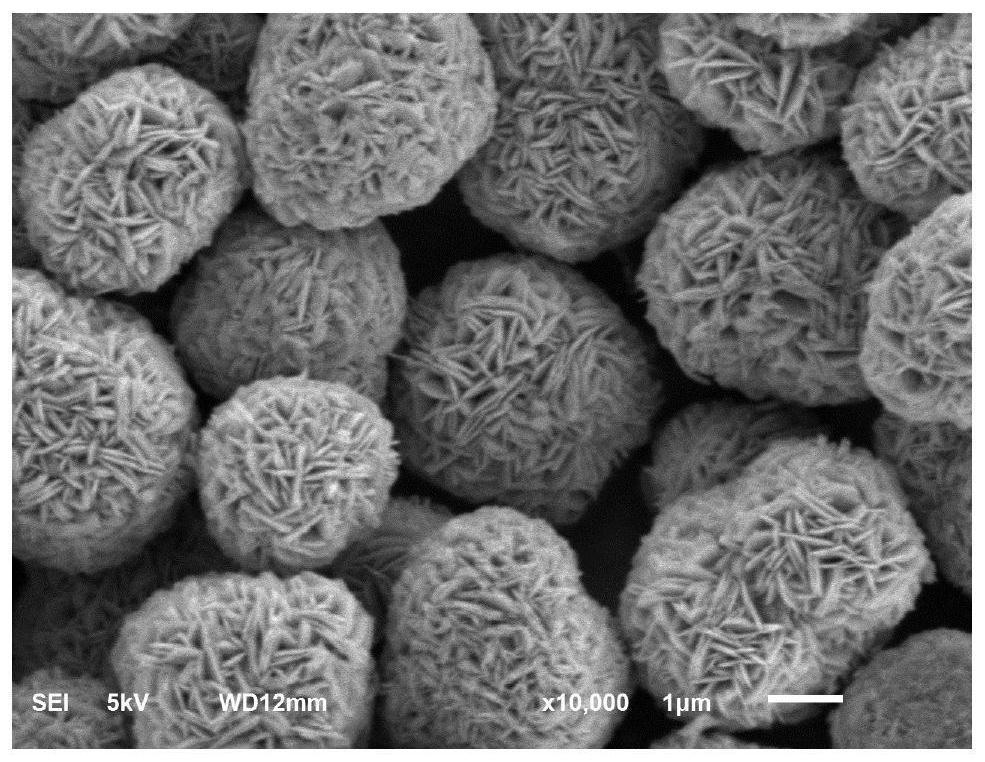

Embodiment 2

[0046] (1) Add a 2 mol / L nickel-cobalt-manganese mixed sulfate solution and a 2 mol / L ammonia solution in parallel flow at a uniform speed. The ammonia solution contains 0.5% tetraethylammonium hydroxide, and at the same time Supply 8 mol / L sodium hydroxide solution to control the pH value of the process to be 11.5-12.0; nitrogen protection during the reaction, stirring speed at 500 rpm and reaction device temperature at about 50°C, control the reaction time to obtain D 50 6.7 µm Ni with a SPAN of 0.81 2+ 0.65 co 2+ 0.1 mn 2+ 0.25 (OH) 2 ;

[0047] (2) Aging the product obtained in step (1) for 2 hours, centrifuging and washing with water 2-3 times;

[0048] (3) Put the product of step (2) into a hot air circulation drying oven, and calcine at a low temperature of 100°C for 2 hours to obtain a low-temperature calcined product;

[0049] (4) transferring the low-temperature calcined product obtained in step (3) to a calciner, and calcining at 500° C. for 5 hours to obtai...

Embodiment 3

[0055] (1) Add 2 mol / L nickel-cobalt-manganese mixed sulfate solution and 2 mol / L ammonia solution in parallel flow at a constant speed. The ammonia solution contains tetraethylammonium hydroxide with a mass fraction of 1%, and at the same time Supply 8 mol / L sodium hydroxide solution to control the pH value of the process to be 11.5-12.0; nitrogen protection during the reaction, stirring speed at 500 rpm and reaction device temperature at about 50°C, control the reaction time to obtain D 50 6.3µm Ni with a SPAN of 1.0 2+ 0.33 co 2+ 0.33 mn 2+ 0.33 (OH) 2 ;

[0056] (2) Aging the product obtained in step (1) for 2 hours, centrifuging and washing with water 2-3 times;

[0057] (3) Put the product of step (2) into a hot air circulation drying oven, and calcine at a low temperature of 105°C for 2 hours to obtain a low-temperature calcined product;

[0058] (4) transferring the low-temperature calcined product obtained in step (3) to a calciner, and calcining at 534° C. fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com