Application of mixed crystalline semiconductor nanoparticles as substrate of surface enhanced laser Raman spectroscopy

A technology of laser Raman spectroscopy and nano-particles, which is applied in the field of nano-materials, can solve the problems of weak enhancement factors and obstacles to wide application, and achieve high Raman sensitivity, improve detection sensitivity, and highly selective surface-enhanced Raman scattering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0150] (1) Preparation of spherical black titanium dioxide with surface-enhanced Raman scattering (SERS) function

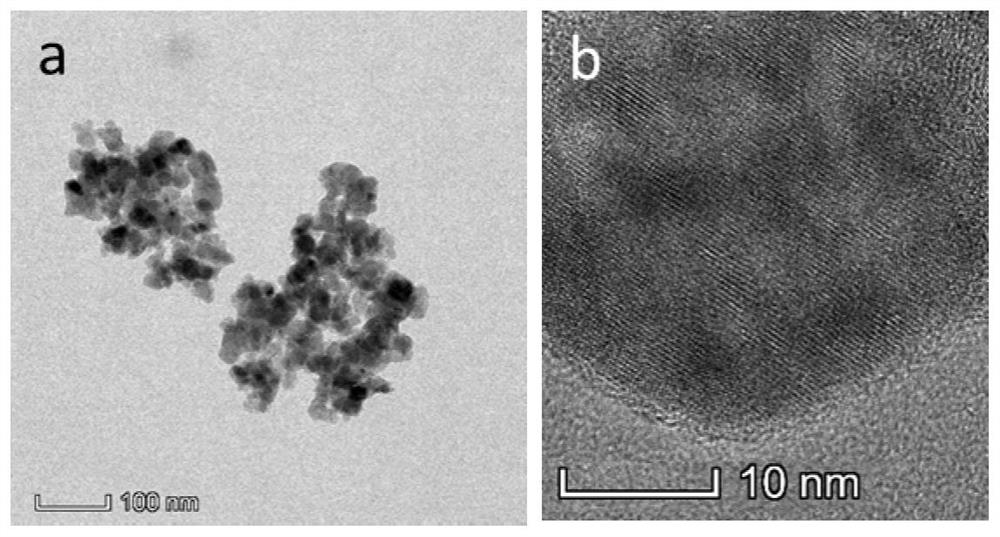

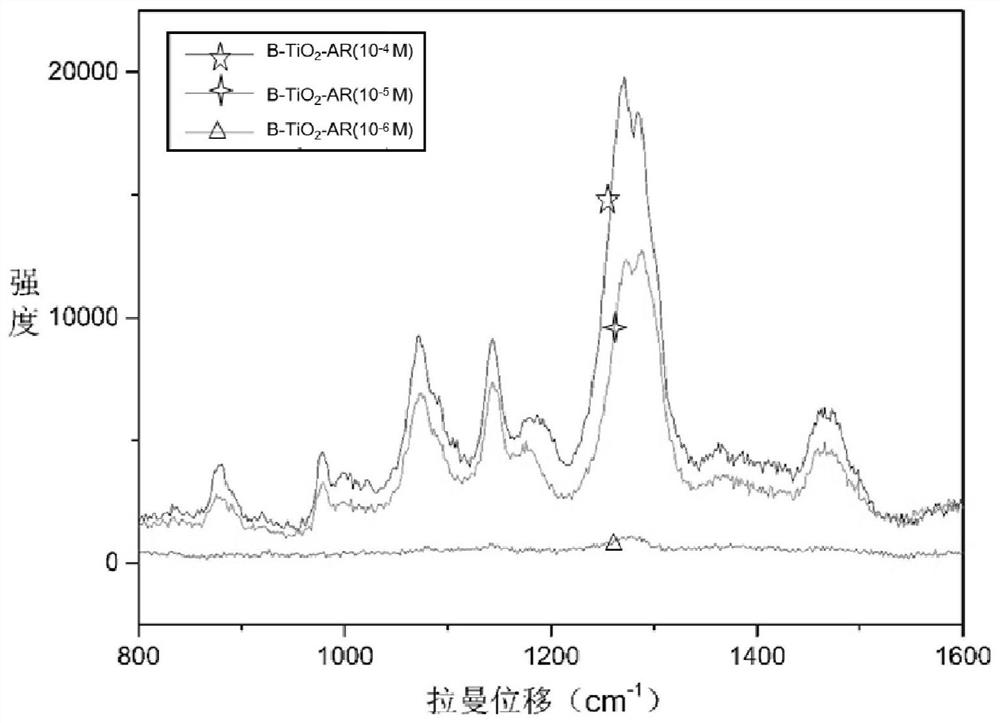

[0151] At room temperature, 4.0 g TiO 2 Nanoparticle powder (P25, anatase, rutile) with 1.5 g NaBH 4 Mix and grind the mixture thoroughly for 30 minutes. The mixture was then transferred to a porcelain boat, placed in a tube furnace, heated from room temperature to 350 °C at a rate of 10 °C / min under an Ar atmosphere, and then kept for 60 min. After natural cooling to room temperature, simply wash several times with deionized water and ethanol to remove unreacted NaBH 4 , and dried at 70 °C to obtain black titanium dioxide. The particle diameter of described black titanium dioxide is 25nm, and the TEM figure of the black titanium dioxide that prepares is as follows figure 2 As shown, it can be seen that black titanium dioxide has a crystal core amorphous shell structure, and the core shell ratio parameter is 25.

[0152] (2) Black titanium dioxide (B-TiO2) ...

Embodiment 2

[0161] (1) Preparation of black ZnO nanosheets with SERS function

[0162] At room temperature, mix 4.0g of ZnO crystal particle powder with 1.5g of NaBH 4 Mix and grind the mixture thoroughly for 30 minutes. The mixture was then transferred to a porcelain boat, placed in a tube furnace, heated from room temperature to 350 °C at a rate of 10 °C / min under an Ar atmosphere, and then kept for 60 min. After natural cooling to room temperature, simply wash several times with deionized water and ethanol to remove unreacted NaBH 4 , and dried at 70°C to obtain black zinc oxide. The particle size of the black zinc oxide is 25nm. It can be seen that the black zinc oxide has a crystal core amorphous shell structure, and the core-shell ratio parameter is 25.

[0163] Other preparation processes of the mixed crystalline ZnO-AR-rBSA-FA composite nanomaterial in Example 2 are the same as in Example 1.

Embodiment 3

[0165] (1) Preparation of black spherical ferric oxide with SERS function

[0166] At room temperature, mix 4.0g ferric oxide crystalline powder with 1.5g NaBH 4 Mix and grind the mixture thoroughly for 30 minutes. The mixture was then transferred to a porcelain boat, placed in a tube furnace, heated from room temperature to 350 °C at a rate of 10 °C / min under an Ar atmosphere, and then kept for 60 min. After natural cooling to room temperature, simply wash several times with deionized water and ethanol to remove unreacted NaBH 4 , and dried at 70°C to obtain black ferric oxide. The particle size of the black ferroferric oxide is 25nm. It can be seen that the black ferric ferric oxide has a crystal core amorphous shell structure, and the core-shell ratio parameter is 25.

[0167] Mixed crystalline Fe in embodiment 3 3 o 4 -Other preparation processes of the AR-rBSA-FA composite nanomaterial are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com