Biochemical composite material as well as preparation method and application thereof

A composite material and biochemical technology, applied in the cross field of microbiology and environmental engineering technology, can solve expensive problems, achieve low cost, promote calcium deposition, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

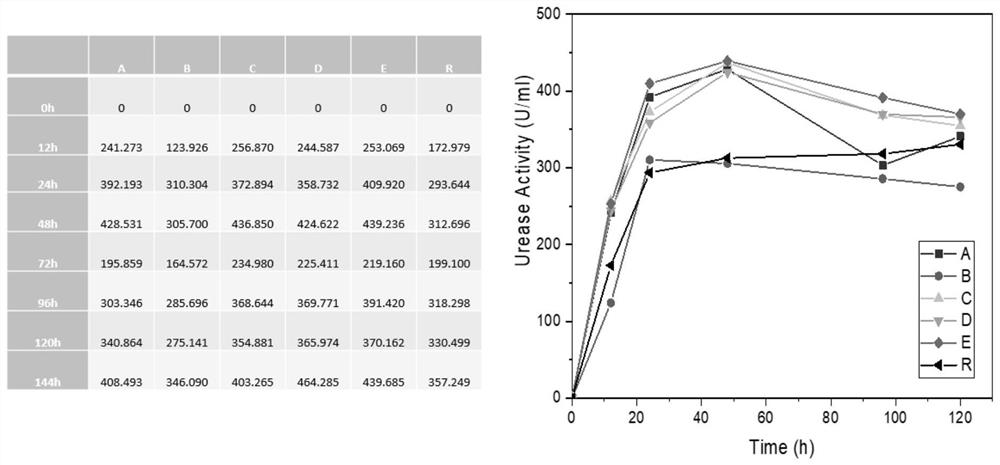

[0050] Example 1, enrichment, purification and urease activity analysis of urease-producing strains

[0051] 1. Enrichment of urease-producing strains

[0052] 1.1 The urease-producing strain of the present invention is isolated from soil collected from an electronic waste site in Guiyu Town, Guangdong Province, and cultured under static culture conditions of 25°C to 35°C for 24 hours. After removing large particles of impurities through a 2mm aperture sieve, take 5 grams of each portion and place them in a clean 50mL conical flask, add 25mL, 85% sodium chloride (NaCl) solution, and prepare 50mg / L of chlorine for the solution Cadmium (CdCl 2 ) and 4% urea;

[0053] 1.2 Put the solution prepared in step 1.1 into a constant temperature shaking incubator. The set temperature of the constant temperature shaking incubator is 37° C., the set speed is 120 rpm, and the incubation time is 7 days.

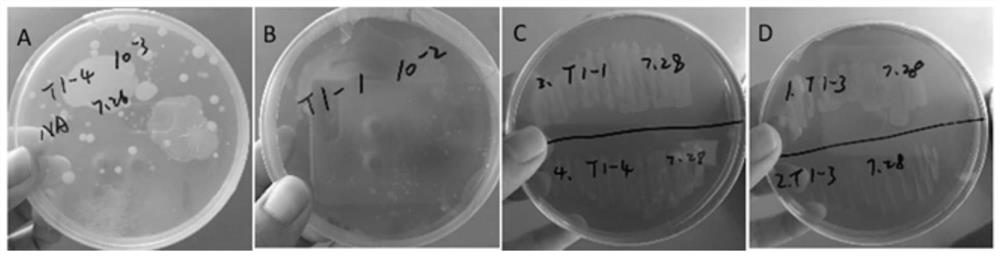

[0054] 2. Purification of urease-producing strains

[0055] 2.1 Take the solution tr...

Embodiment 2

[0090] Embodiment 2, a kind of biochemical composite material and preparation method thereof

[0091] 1) According to the urease activity and bacterial optical density data obtained in step 3.8, reasonably select Bacillus sp.WA with high urease activity and high optical density as one of the raw materials for biochemical composite materials, and inoculate them into a petri dish based on nutrient agar , stored in a refrigerator at 4°C;

[0092] 2) Prepare urea nutrient solution (NBU) as the formation medium of biochemical composite materials, the specific method is:

[0093] Weigh 2.6 grams of nutrient broth powder and dissolve it in 170 mL of deionized water;

[0094] Continuing from the previous step, add 20 mL of 250 mM pinhole sterilized calcium chloride (CaCl 2 ) solution;

[0095] Continuing from the previous step, add 10mL of 40% pinhole sterilized urea solution;

[0096] Continuing from the previous step, add 60 μL of pinhole sterilized sodium hydroxide (NaOH) solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com