Low-carbon environment-friendly unfired ceramsite filter material as well as preparation method and application thereof

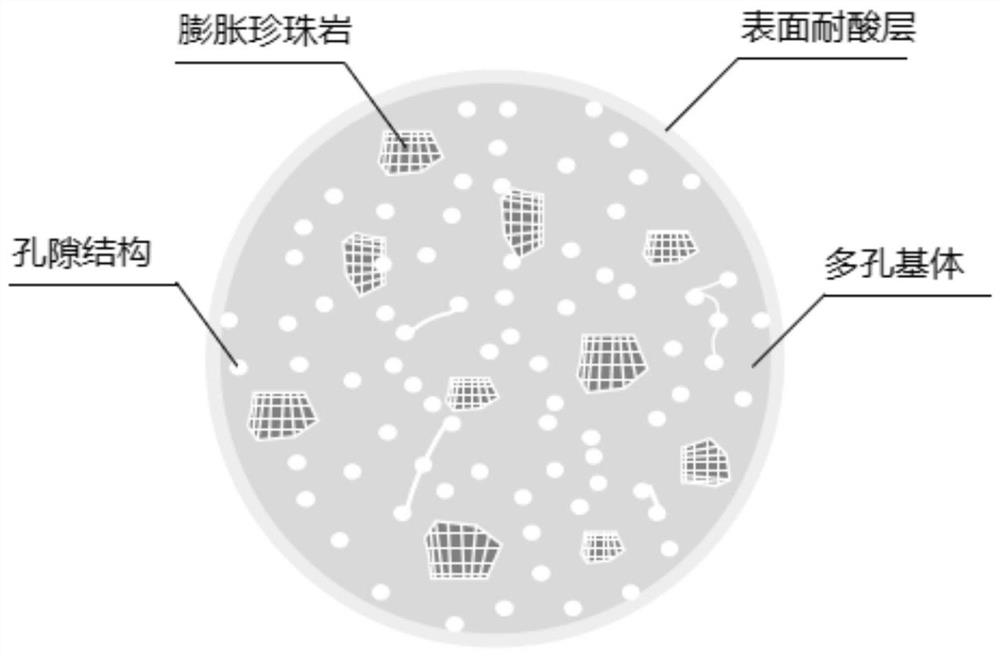

A ceramsite filter material, low-carbon and environmentally friendly technology, applied in the field of water treatment, can solve the problems of large plant construction investment, large water flow resistance, complex process technology, etc., achieve excellent comprehensive performance, avoid filter layer mud accumulation, accumulation of porosity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

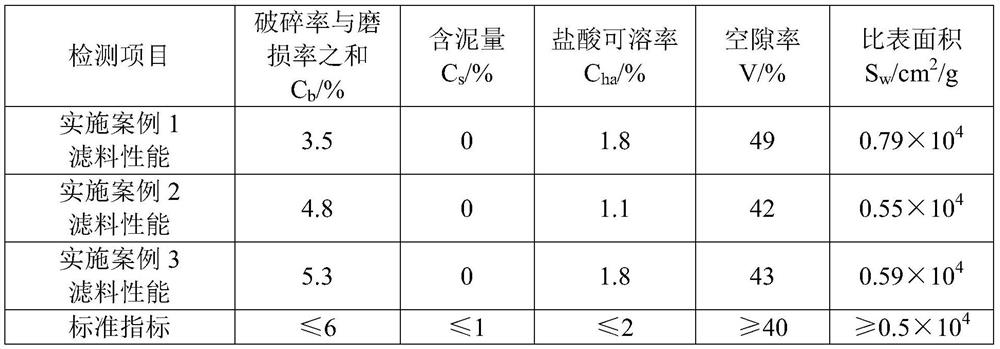

[0043] Take by weighing 6% concentrated sulfuric acid of cement mass, add water to dilute according to 1:5 (wt%), mix and stir with cement to form acid excitation material; acid excitation material, quartz powder and expanded perlite are according to the mass ratio of 20:70:10 Mix and stir, then add water with 35% of the total mass of the matrix and stir into a slurry; add aluminum paste powder with a cement mass of 0.8% and stir evenly, then pour the slurry into a pellet machine and extrude and granulate into balls (particle diameter 8mm left and right); After molding, the particles are left standing at room temperature for 5-6 hours → 90°C atmospheric pressure steam curing (heating 2h, constant temperature 4h, cooling 1h) → 1MPa / 180°C high-pressure steam curing (heating 2.5h, constant temperature 3h, cooling 1h )→dry at 100°C and cool to room temperature. Detect the bulk density of the granules after cooling and place them in the disc granulator, and weigh 15kg / m based on th...

Embodiment 2

[0046]Weigh 8% of the total mass of mineral powder and metakaolin (aluminosilicate material) concentrated hydrochloric acid, dilute with water according to 2:5.5 (wt%), mix and stir with mineral powder and metakaolin (mass ratio 7:3) to form acid Exciting material; mixing acid stimulating material: finely ground sand: expanded perlite according to the mass ratio of 30:60:10, then adding water with 25% of the total mass of the matrix and stirring to form a slurry; mixing biological protein foaming agent with water Mix at a ratio of 1:20, add an appropriate amount of foam stabilizer, prepare foam with a physical foaming machine, then add 5% foam to the slurry and stir evenly, pour it into a pellet machine, extrude and granulate into balls (with a particle size of about 8mm) ); After forming, the particles are left to stand at room temperature for 5-6h→90°C atmospheric pressure steam curing (heating 2h, constant temperature 4h, cooling 1h)→1MPa / 180°C high-pressure steam curing (he...

Embodiment 3

[0049] Weigh the concentrated nitric acid of 6% of the total mass of cement, fly ash and zeolite powder, dilute with water according to 1:6 (wt%), mix and stir with cement, fly ash and zeolite powder (mass ratio 5:3:2) to form Acid excitation material; mix and stir acid excitation material: finely ground sand: expanded perlite according to the mass ratio of 30:50:20, then add 40% water of the total mass of the matrix and stir to form a slurry; add 1% bicarbonate of cement mass Sodium and stir evenly, then pour the slurry into the pellet machine and extrude into pellets (about 8mm in diameter); after forming, the pellets should be kept at room temperature for 5 to 6 hours→90°C for normal pressure steam curing (heating for 2 hours) , constant temperature for 4 hours, cooling for 1 hour) → 1MPa / 180°C high-pressure steam curing (heating for 2.5 hours, constant temperature for 3 hours, cooling for 1 hour) → drying at 100°C and cooling to room temperature. Detect the bulk density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com