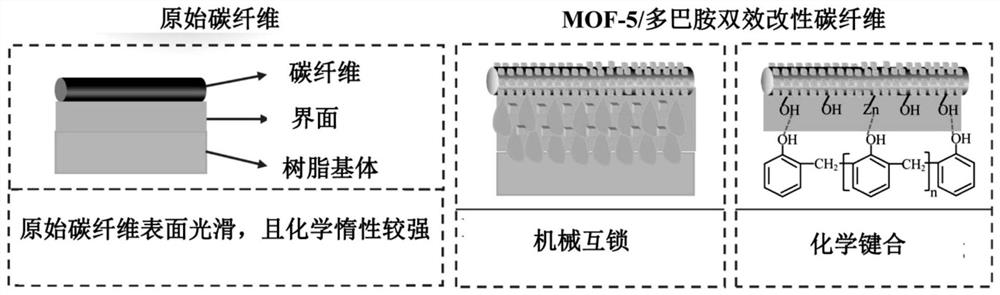

MOF-5/dopamine double-effect enhanced paper-based friction material and preparation method thereof

A paper-based friction material, MOF-5 technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, special paper, natural cellulose pulp/paper, etc., can solve the problems of no related research and achieve improved friction Effects of wear performance, increase in effective contact area, and promotion of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] see figure 1 , a MOF-5 / dopamine dual-effect reinforced paper-based friction material and a preparation method thereof, comprising the following steps:

[0056] Step 1: Take 15g of carbon fiber and soak it in acetone for 12-48 hours to remove the sizing agent and other impurities on the surface of the fiber. After completion, rinse it with deionized water for 3-5 times and dry it in an oven at a temperature of 80-150°C for 12-24 hours. , drying to obtain carbon fiber I with a clean surface;

[0057] Step 2: Dissolve 1.0 to 2.0 g of tris (Tris buffer) in 0.97 to 1.45 L of deionized water at room temperature and stir magnetically to obtain solution A, then dissolve 1.8 to 2.2 g of dopamine in 0.03 ~0.05L deionized water, conduct ultrasonic dispersion to obtain solution B;

[0058] Step 3: Use hydrochloric acid to adjust the pH of solution A to 8-9. During the continuous magnetic stirring process, the magnetic stirring rotation speed is 1000-1500r, pour solution B into so...

Embodiment 1

[0066] Example 1 Blank example and blank paper-based friction material without carbon fiber modification in the prior art

[0067] Step 1: Decompose carbon fiber, aramid fiber and pulp fiber to form a fiber mixture. The mass ratio of carbon fiber, aramid fiber, pulp fiber and filler is 1.2:1.0:1.3:3.0. Add fillers including barium sulfate, graphite, Al2O3 and talcum powder were used to prepare wet samples through the principle of vacuum filtration and pulping and papermaking, and dried in an oven at a temperature of 75°C for 4 hours to obtain dry samples for later use;

[0068]Step 2: Impregnate the dry sample obtained in Step 1 in the modified phenolic resin with an impregnation concentration of 20%. After completion, it is dried at room temperature and cured by hot pressing at a temperature of 150°C, a curing time of 5 minutes, and a pressure of 15 Pa. Thus a blank paper-based friction material was obtained.

Embodiment 2

[0071] Step 1: Take 15g of carbon fiber and soak it in acetone for 24 hours to remove the sizing agent and other impurities on the surface of the fiber. After completion, rinse it with deionized water for 3 times and dry it in an oven at 80°C for 12 hours. Dry to obtain carbon fiber with a clean surface I;

[0072] Step 2: Dissolve 1.0 g of tris (Tris buffer) in 0.97 L of deionized water at room temperature, and perform magnetic stirring to obtain solution A, then dissolve 1.8 g of dopamine in 0.03 L of deionized water, and carry out Ultrasonic dispersion to obtain solution B;

[0073] Step 3: Use hydrochloric acid to adjust the pH of solution A to 8. During the continuous magnetic stirring process, the magnetic stirring rotation speed is 1000r, pour solution B into solution A, and make it fully mixed. Put the carbon fiber I obtained in step 1 into the above mixed solution, stir at room temperature, and dry in an oven after the reaction is completed at a temperature of 80°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com