Steel austenite grain size etchant and preparation method and application thereof

A technology of austenite grain and steel austenite, applied in the field of etchant application, can solve the problems of high level requirements of inspectors, toxicity, difficult to grasp, etc., to solve the problem of polluting the environment, affecting public safety, and saving time and cost, the effect of simple and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A steel austenite grain size etchant comprises carboxyl compound, surfactant and diluent. Wherein, the carboxyl compound is oxalic acid, the surfactant is sodium dodecylbenzenesulfonate, and the diluent is water and ethanol. On a mass basis, the component ratio of oxalic acid and sodium dodecylbenzenesulfonate is 1:0.2, and the ratio of the mass sum of oxalic acid and sodium dodecylbenzenesulfonate to the mass of diluent is 5.5: 100; in the diluent, the mass ratio of water and ethanol is 8:1. The steel austenite grain size etchant in this embodiment is obtained by uniformly mixing the above raw materials.

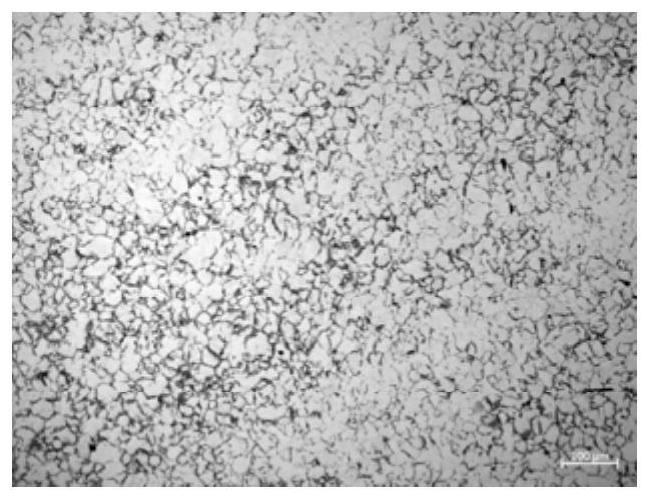

[0031] The etchant of this embodiment is used to etch the train wheel steel (ER8). Before the etching, the steel is heat-treated according to the direct hardening method in GB / T6394 "Metal Average Grain Size Measurement Method", and observed with a metallographic microscope. , the obtained austenite grain size result is 8.0 grade as figure 1 shown. Depend on fig...

Embodiment 2

[0033] A steel austenite grain size etchant comprises carboxyl compound, surfactant and diluent. Wherein, the carboxyl compound is oxalic acid, the surfactant is sodium dodecylbenzenesulfonate, and the diluent is water and ethanol. In terms of mass, the component ratio of oxalic acid and sodium dodecylbenzenesulfonate is 1:0.25, and the mass ratio of the mass sum of oxalic acid and sodium dodecylbenzenesulfonate to the diluent is 6:100 ; The mass ratio of water and ethanol is 6.5:1. The steel austenite grain size etchant in this embodiment is obtained by uniformly mixing the above raw materials.

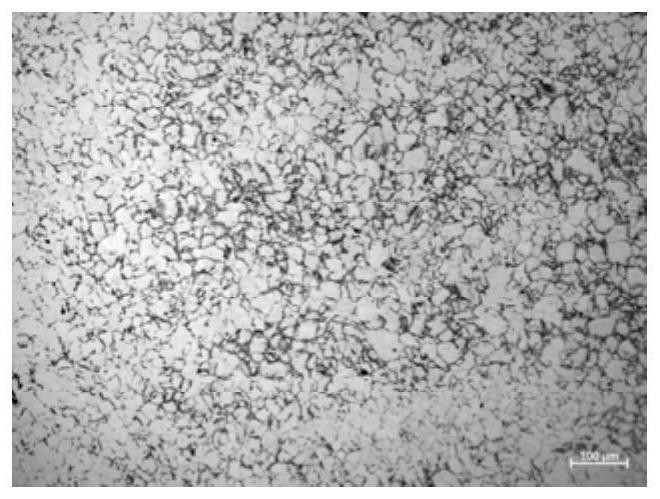

[0034] Adopt the etching agent of present embodiment to etch train wheel steel (ER9), and observe with metallographic microscope, the austenite grain size result that obtains is 8.0 grades such as figure 2 shown. Depend on figure 2 It can be seen that the etching effect of this embodiment is good, the grain boundaries (black thin lines) of the train wheel steel (ER9) are clear,...

Embodiment 3

[0036] A steel austenite grain size etchant comprises carboxyl compound, surfactant and diluent. Wherein, the carboxyl compound is oxalic acid, the surfactant is sodium lauryl sulfate, and the diluent is water and ethanol. In terms of mass, the mass ratio of oxalic acid and sodium lauryl sulfate is 1:0.1, the ratio of the mass sum of oxalic acid and sodium lauryl sulfate to the mass of diluent is 7:100, water and ethanol The mass ratio is 6.5:1. The steel austenite grain size etchant in this embodiment is obtained by uniformly mixing the above raw materials.

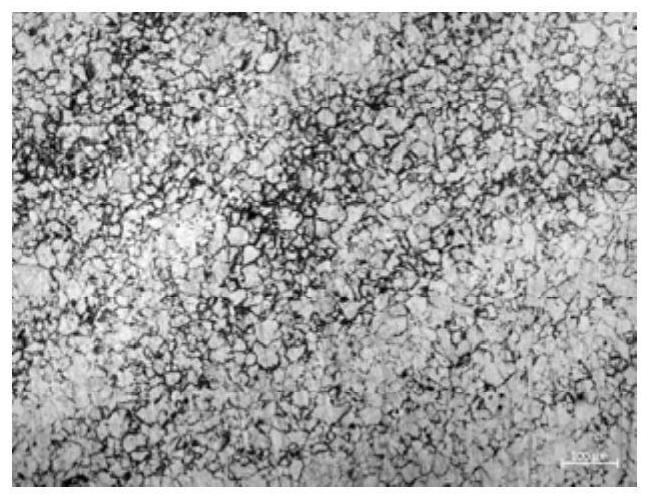

[0037] Adopt the etchant of present embodiment to etch train wheel steel (CL60), and observe with metallographic microscope, the austenite grain size result that obtains is 8.0 grades such as image 3 shown. Depend on image 3 It can be seen that the etching effect of this embodiment is good, the grain boundaries (black thin lines) of the train wheel steel (CL60) are clear, and the grains are completely displayed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com