Thermal insulation ceramic tile with near-infrared light reflection function as well as preparation method and application of thermal insulation ceramic tile

A near-infrared light and ceramic tile technology is applied in the field of thermal insulation ceramic tiles, which can solve the problems of poor compatibility between infrared reflective materials and ceramic materials, restricting the application of thermal insulation ceramics on building exterior walls, and reducing the absorption of sunlight on building exterior walls. Overcome poor bonding, enhance overall strength, and block the effect of outdoor high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

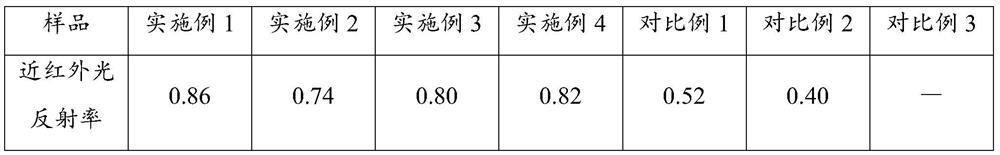

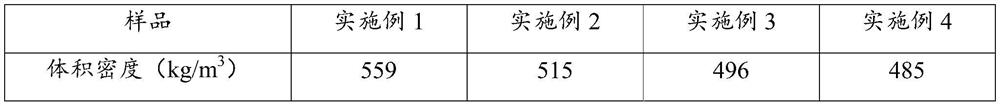

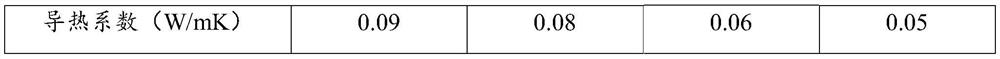

Embodiment 1

[0040] A heat-preserving ceramic tile comprises a foamed ceramic layer and a dense layer from bottom to top, wherein: the thickness of the dense layer is 3mm, and the thickness of the foamed ceramic layer is 20mm.

[0041] The raw materials for preparing the dense layer include by weight: 95 parts of the base material, and 5 parts of the near-infrared reflective material rutile titanium dioxide; the chemical composition of the base material includes by weight percentage: 60% of SiO 2 , 12% Al 2 o 3 , 10% CaO, 8% MgO, 3% K 2 O, 4% Na 2 O, 0.3% Fe 2 o 3 and a loss on ignition of 2.6%, the melting onset temperature of the base material is 856°C.

[0042] The raw materials for preparing the foamed ceramic layer include by weight: 25 parts of porcelain ceramic tile waste, 30 parts of feldspar, 25 parts of black mud, 5 parts of ball soil, 10 parts of quartz sand, 5 parts of bauxite, silicon carbide 0.5 parts; the particle size of silicon carbide is 1000 mesh; the plasticity in...

Embodiment 2

[0048] A heat-preserving ceramic brick, comprising a foamed ceramic layer and a dense layer from bottom to top, wherein: the thickness of the dense layer is 5mm, and the thickness of the foamed ceramic layer is 30mm.

[0049] The raw materials for preparing the dense layer include by weight: 96 parts of base material, and 4 parts of bismuth vanadate as a near-infrared light reflection material; the chemical composition of the base material includes by weight percentage: 62% of SiO 2 , 13% Al 2 o 3 , 8% CaO, 8% MgO, 2% K 2 O, 3% Na 2 O, 0.2% Fe 2 o 3 and a loss on ignition of 3.8%, the melting onset temperature of the base material is 863°C.

[0050] The raw materials for preparing the foamed ceramic layer include by weight: 35 parts of porcelain ceramic tile waste, 25 parts of feldspar, 25 parts of black mud, 5 parts of ball soil, 10 parts of quartz sand, 5 parts of bauxite, silicon carbide 0.75 parts; the particle size of silicon carbide is 800 mesh; the plasticity inde...

Embodiment 3

[0056] A heat-preserving ceramic brick, comprising a foamed ceramic layer and a dense layer from bottom to top, wherein: the thickness of the dense layer is 5mm, and the thickness of the foamed ceramic layer is 40mm.

[0057] The raw materials for preparing the dense layer include by weight: 97 parts of base material, 3 parts of near-infrared light reflective material titanium-doped chromium oxide; the chemical composition of the base material includes by weight percentage: 63% of SiO 2 , 13% Al 2 o 3 , 8% CaO, 6% MgO, 3% K 2 O, 3% Na 2 O, 0.5% Fe 2 o 3 and a loss on ignition of 3.5%, the melting onset temperature of the base material is 882°C.

[0058] The raw materials for preparing the foamed ceramic layer include by weight: 25 parts of porcelain ceramic tile waste, 30 parts of feldspar, 20 parts of black mud, 5 parts of ball soil, 10 parts of quartz sand, 10 parts of bauxite, silicon carbide 0.5 parts; the particle size of silicon carbide is 1200 mesh; the plasticity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com