Concentrated leachate treatment system and method

A treatment system and treatment method technology, applied in the field of landfill leachate treatment, can solve the problems of reducing heat exchange efficiency and evaporation energy efficiency ratio, reducing operation stability, and secondary pollution of groundwater, so as to avoid scaling of heat exchange surface and apply Strong resistance, not easy to scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

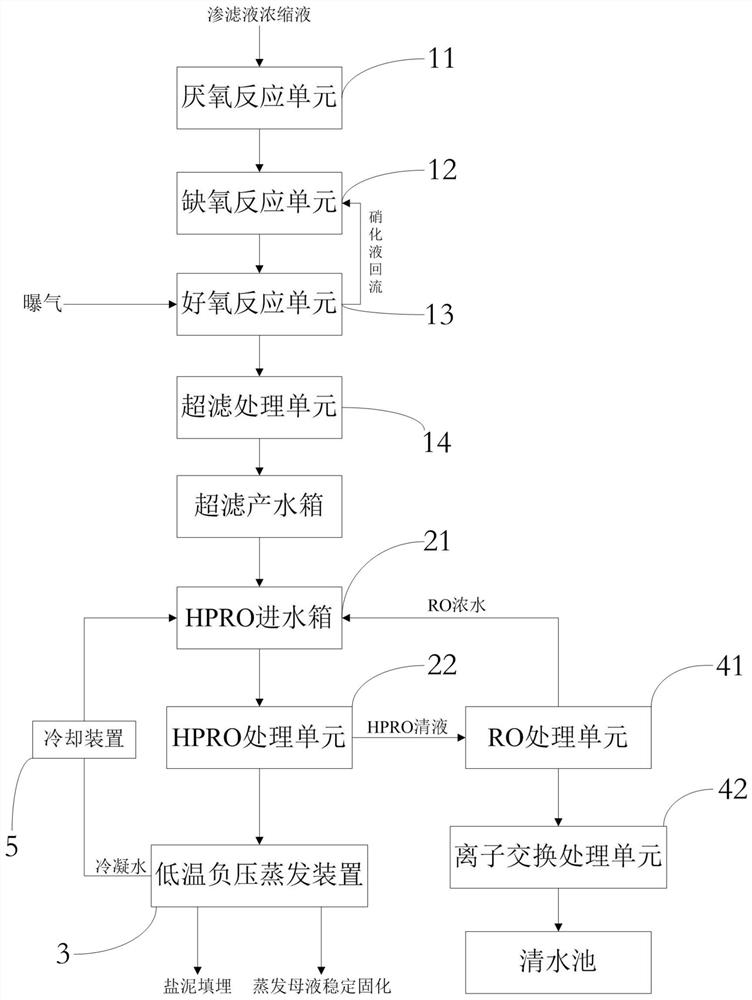

[0027] like figure 1 , an embodiment of the present invention provides a leachate concentrate treatment system, including a membrane bioreactor, an HPRO treatment unit 22 and a low-temperature negative pressure evaporation device 3, wherein the water production pipeline of the membrane bioreactor and the HPRO treatment The water inlet of the unit 22 is connected, the concentrated liquid outlet pipe of the HPRO processing unit 22 is connected to the low-temperature negative pressure evaporation device 3, and the clear liquid outlet pipe of the HPRO processing unit 22 is connected to a clear liquid processing mechanism.

[0028] The above-mentioned membrane bioreaction mechanism can adopt conventional MBR processing equipment. In one of the examples, as figure 1 , the membrane bioreaction mechanism includes anaerobic reaction unit 11, anoxic reaction unit 12, aerobic reaction unit 13 and ultrafiltration treatment unit 14 connected in sequence, and the water production pipeline ...

Embodiment 2

[0046] An embodiment of the present invention provides a leachate concentrate treatment method, comprising:

[0047] The leachate concentrate is introduced into a membrane bioreactor for treatment;

[0048] The water produced by the membrane bioreactor is introduced into the HPRO treatment unit 22 for treatment, the obtained HPRO clear liquid is treated and then discharged up to the standard, and the obtained HPRO concentrated liquid is subjected to low-temperature negative pressure evaporation treatment, wherein the salt sludge produced by low-temperature negative pressure evaporation and the evaporated mother liquor are respectively harmlessly disposed of.

[0049] Further, the leachate concentrate treatment method also includes:

[0050] The condensed water produced by low-temperature negative-pressure evaporation is introduced into the HPRO treatment unit 22 for circulation treatment.

[0051] Further, the condensed water is cooled to a set temperature and then mixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com