Novel slewing bearing for tooth surface self-lubrication and preparation method of novel slewing bearing

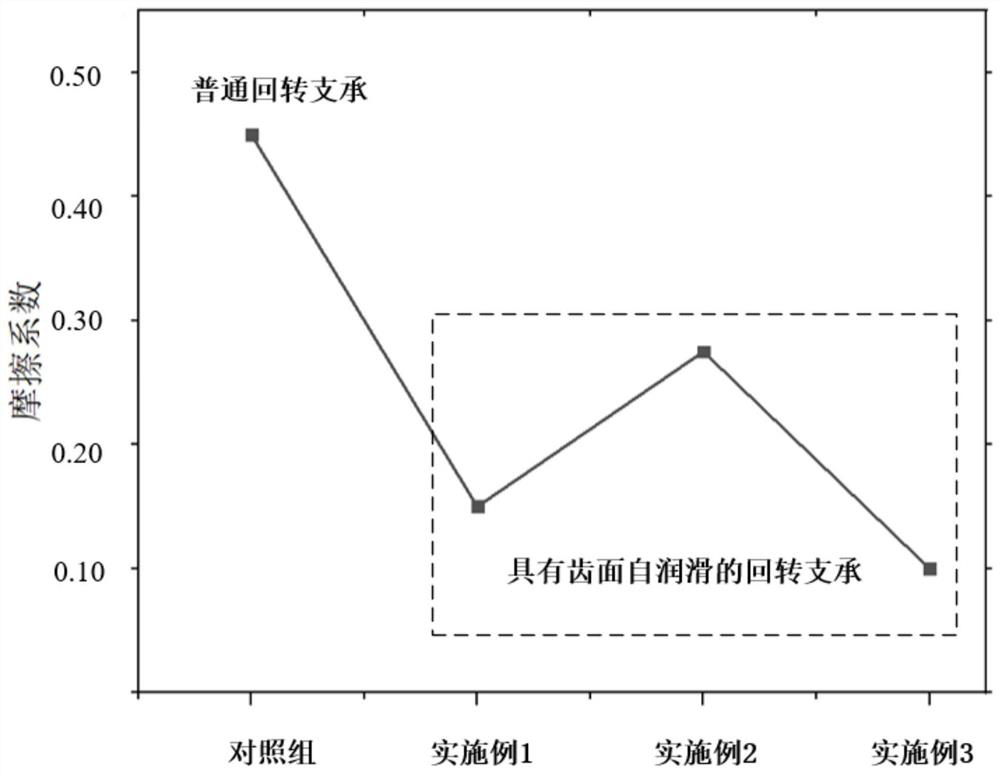

A slewing bearing and self-lubricating technology, which is applied in metal processing equipment, metal material coating technology, transportation and packaging, etc., can solve problems such as ineffective lubrication and protection, failure to meet work requirements, and grease film damage. Achieve excellent tribological properties, improve stability and service life, and reduce the effect of material wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

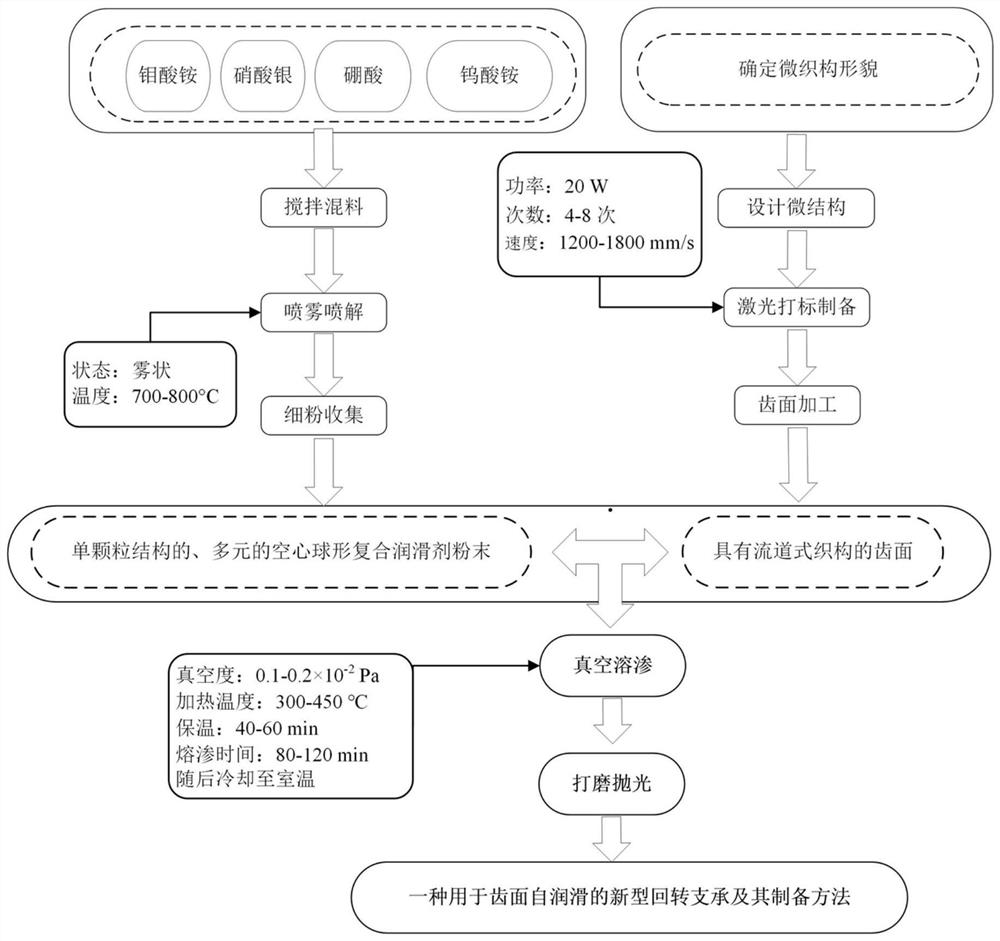

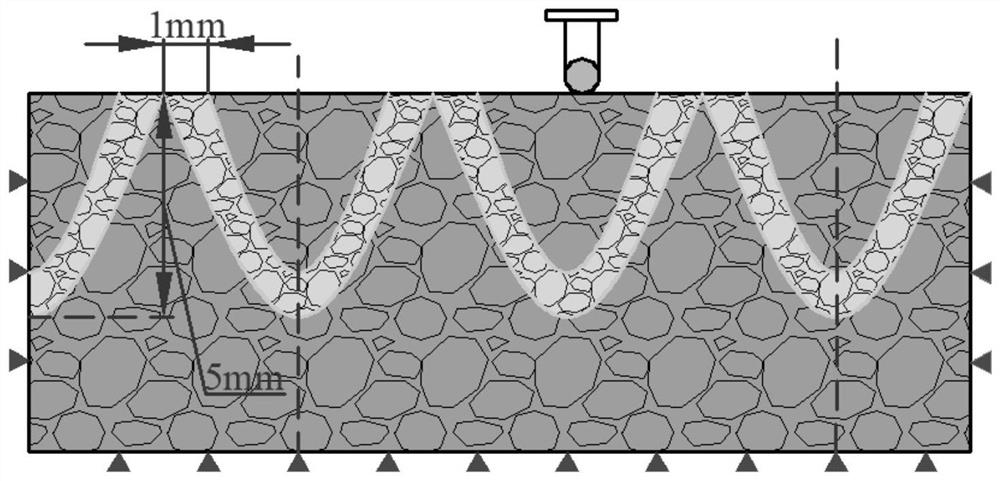

[0043] A new type of slewing bearing for tooth surface self-lubrication and its preparation method, characterized in that the tooth surface of the slewing bearing is processed with laser marking technology to process the micro-texture of the flow channel, and the composite spherical powder is used as the solid lubricating phase to fill the micro-texture In the structure, a self-lubricating composite material with a lubricating phase on the tooth surface is obtained.

[0044] In this embodiment, the geometric parameters of the micro-texture of the tooth surface flow channel of the slewing bearing are: the aperture is 600 μm; the aperture spacing: 300 μm; the flow channel depth: 300 μm;

[0045] The raw materials in the composite spherical powder include by mass percentage: 10wt.% of ammonium molybdate solution, 60wt.% of silver nitrate solution, 3wt.% of boric acid solution and 6wt.% of ammonium tungstate solution;

[0046] According to the above scheme, the particle size range...

Embodiment 2

[0063] A new type of slewing bearing for tooth surface self-lubrication and its preparation method, characterized in that the tooth surface of the slewing bearing is processed with laser marking technology to process the micro-texture of the flow channel, and the composite spherical powder is used as the solid lubricating phase to fill the micro-texture In the structure, a self-lubricating composite material with a lubricating phase on the tooth surface is obtained.

[0064] In this embodiment, the geometric parameters of the micro-texture of the tooth surface flow channel of the slewing bearing are: the aperture is 700 μm; the aperture spacing: 400 μm; the flow channel depth: 500 μm;

[0065] The raw materials in the composite spherical powder include by mass percentage: 15wt.% of ammonium molybdate solution, 65wt.% of silver nitrate solution, 4wt.% of boric acid solution and 10wt.% of ammonium tungstate solution;

[0066] According to the above scheme, the particle size rang...

Embodiment 3

[0083] A new type of slewing bearing for tooth surface self-lubrication and its preparation method, characterized in that the tooth surface of the slewing bearing is processed with laser marking technology to process the micro-texture of the flow channel, and the composite spherical powder is used as the solid lubricating phase to fill the micro-texture In the structure, a self-lubricating composite material with a lubricating phase on the tooth surface is obtained.

[0084] In this embodiment, the geometric parameters of the micro-texture of the tooth surface flow channel of the slewing bearing are: the aperture is 800 μm; the spacing between the apertures: 500 μm; the depth of the flow channel: 500 μm;

[0085] The raw materials in the composite spherical powder include by mass percentage: 20wt.% of ammonium molybdate solution, 70wt.% of silver nitrate solution, 5wt.% of boric acid solution and 12wt.% of ammonium tungstate solution;

[0086] According to the above scheme, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com