Compound of metal organic framework material and two-dimensional material as well as preparation and application of compound

A technology of metal-organic frameworks and two-dimensional materials, applied in organic compound/hydride/coordination complex catalysts, special compound water treatment, water pollutants, etc., can solve the problem of low utilization of active sites and easy agglomeration , high surface energy and other issues, to achieve the effect of avoiding agglomeration, good stability and chemical stability, and improving degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

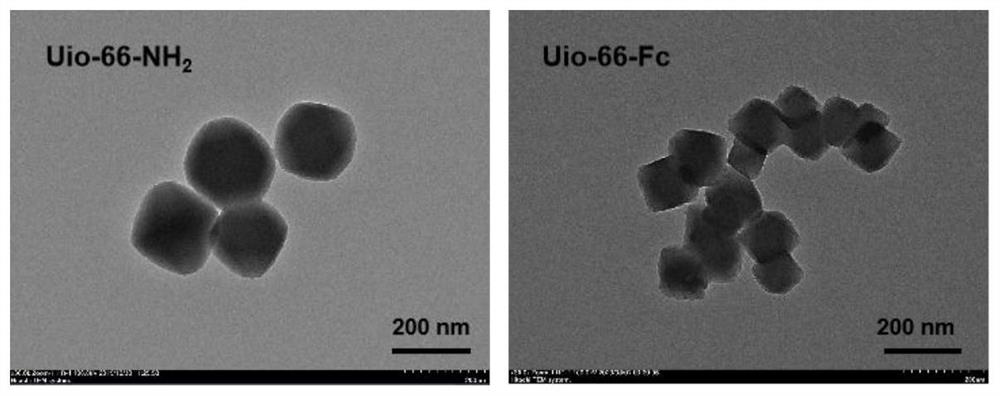

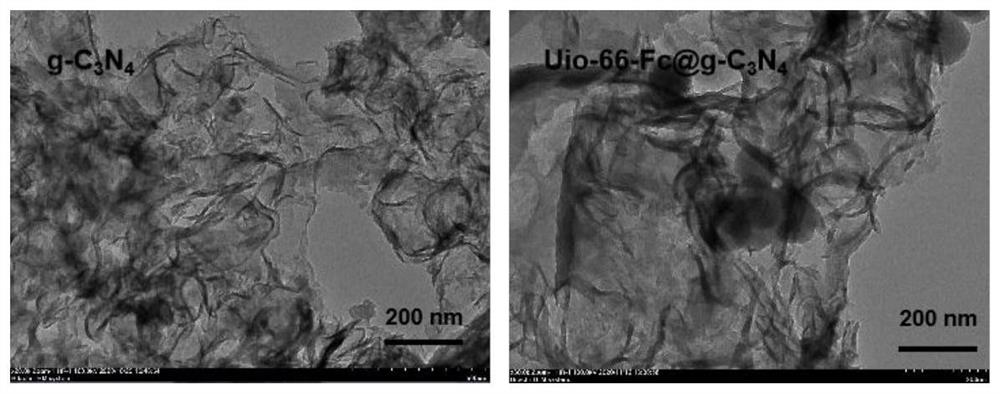

[0084] Weigh 582.5mg of zirconium chloride and 416.0mg of 2-aminoterephthalic acid into the lining of a polytetrafluoroethylene reactor, add 75mL of N,N'-dimethylformamide and 7.15mL of acetic acid solution, and sonicate for 30min A uniform dispersion was obtained, sealed and placed in an electric blast drying oven, and reacted at 120° C. for 12 hours. After naturally cooling to room temperature, the obtained dispersion was centrifuged at 3000rpm / min for 30min, and the brown precipitate was collected, washed three times with N,N'-dimethylformamide and absolute ethanol solution, and dried in vacuum at 40°C for 24h , get Uio-66-NH 2 dry powder.

[0085] Weigh 200mg Uio-66-NH respectively 2 and 400 mg of ferrocene formaldehyde powder were ultrasonically dispersed in 40 mL of absolute ethanol, and heated to 100 ° C for 24 h. After the reaction, the precipitate was collected by centrifugation, washed with absolute ethanol, and dried to obtain ferrocene-modified Uio-66-NH 2 -0.5...

Embodiment 2

[0088] Weigh 20g of urea into a covered quartz boat, heat it in the air at a rate of 2.5°C / min from room temperature to 550°C after sealing, hold for 4 hours and then cool with the furnace. The cooled powder was collected, and light yellow CN powder was obtained after grinding.

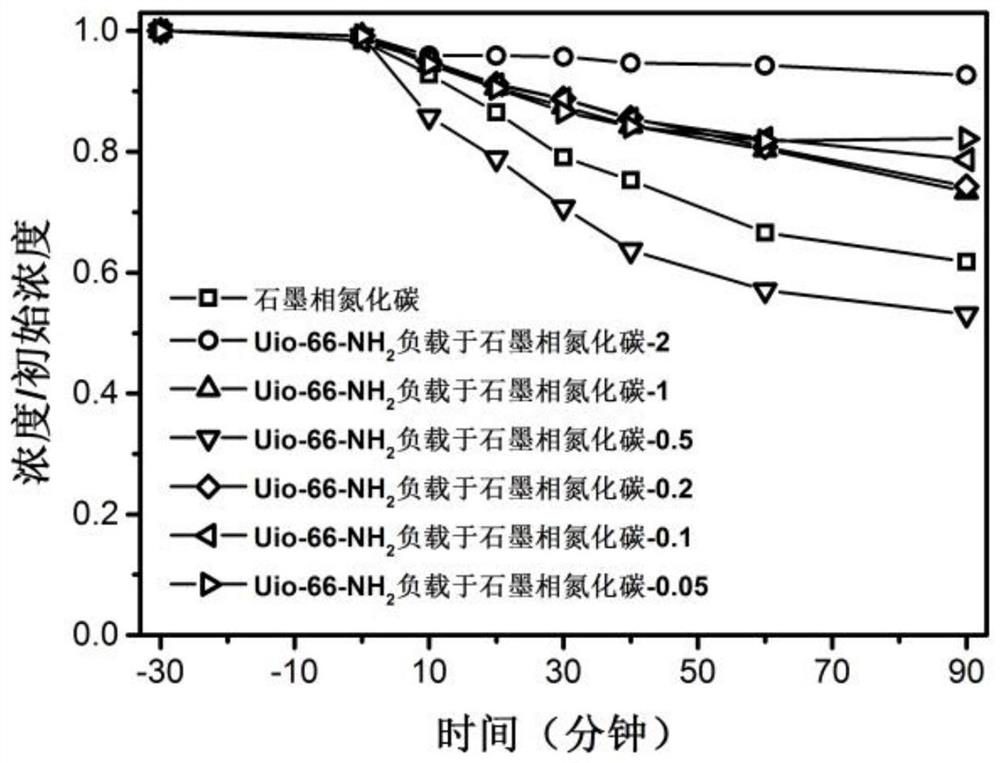

[0089] Weigh 50mg Uio-66-NH 2 and 100 mg of graphitic carbon nitride powder were ultrasonically dispersed in 25 mL of deionized water to obtain dispersions A and B. Subsequently, 1 mL of 5% polyethylene glycol solution was added to B to obtain dispersion C. A and C were mixed and stirred for 30 minutes to obtain a uniform dispersion. Then the obtained dispersion liquid was placed in a reaction kettle, sealed, and reacted at 100° C. for 8 hours. The precipitate was collected by centrifugation, washed three times with absolute ethanol, and dried in vacuum to obtain Uio-66-NH 2 Loaded on graphite phase carbon nitride-0.5 powder. Uio-66-NH 2 The load capacity can be passed through Uio-66-NH 2 The f...

Embodiment 3

[0091] Weigh 50 mg of ferrocene-modified Uio-66-NH 2 -0.5 and 125 mg of graphitic carbon nitride powder were ultrasonically dispersed in 25 mL of deionized water to obtain dispersions A and B, respectively. Subsequently, 1 mL of 5% polyethylene glycol solution was added to B to obtain dispersion C. A and C were mixed and stirred for 30 minutes to obtain a uniform dispersion. Then the obtained dispersion liquid was placed in a reaction kettle, sealed, and reacted at 100° C. for 8 hours. The precipitate was collected by centrifugation, washed three times with absolute ethanol, and dried in vacuum to obtain ferrocene-modified Uio-66-NH 2 -0.5 loaded on graphitic carbon nitride -0.4 powder. Ferrocene-modified Uio-66-NH 2 -X loading can be achieved by ferrocene-modified Uio-66-NH 2 The feeding ratio between -X and graphite phase carbon nitride can be precisely adjusted, and the feeding ratio range can be selected between 1:0.01-1:100.

[0092] attached by figure 2 It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com