Low-temperature stretchable flexible stress sensor based on 3D printing and preparation method

A stress sensor and 3D printing technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of instability and failure of flexible sensor devices, achieve high sensitivity, good stretchability, and broaden the research field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

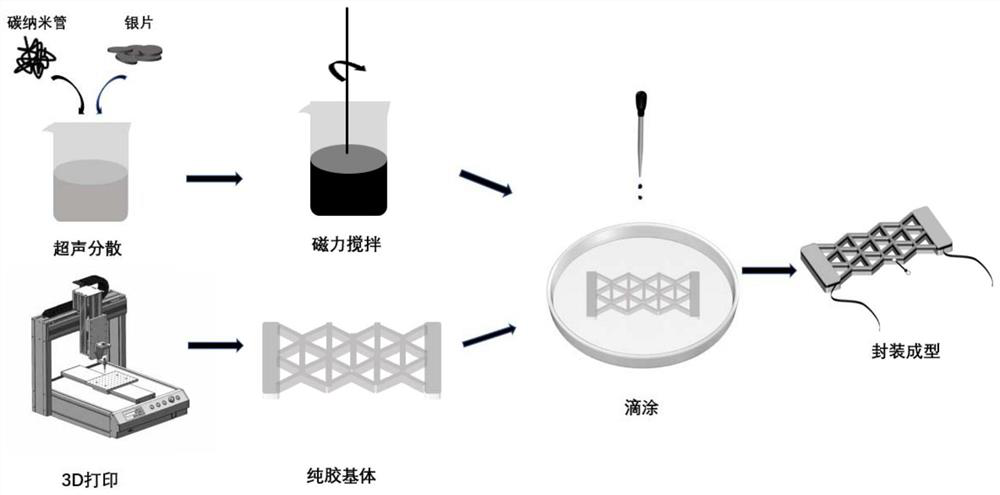

[0038] like figure 1 As shown, a low-temperature stretchable flexible stress sensor based on 3D printing disclosed by the present invention and its preparation method include the following steps:

[0039] Step 1, mixing CNTs and Ag powder to obtain a composite conductive material with zero temperature coefficient;

[0040] Step 2, preparing a flexible substrate by means of 3D printing;

[0041] Step 3, apply the composite conductive substance obtained in step 1 on the flexible substrate prepared in step 2, and lead out electrodes to obtain a semi-finished flexible stress sensor;

[0042] In step 4, the semi-finished flexible stress sensor obtained in step 3 is packaged with PDMS solution to obtain a low-temperature stretchable flexible stress sensor based on 3D printing.

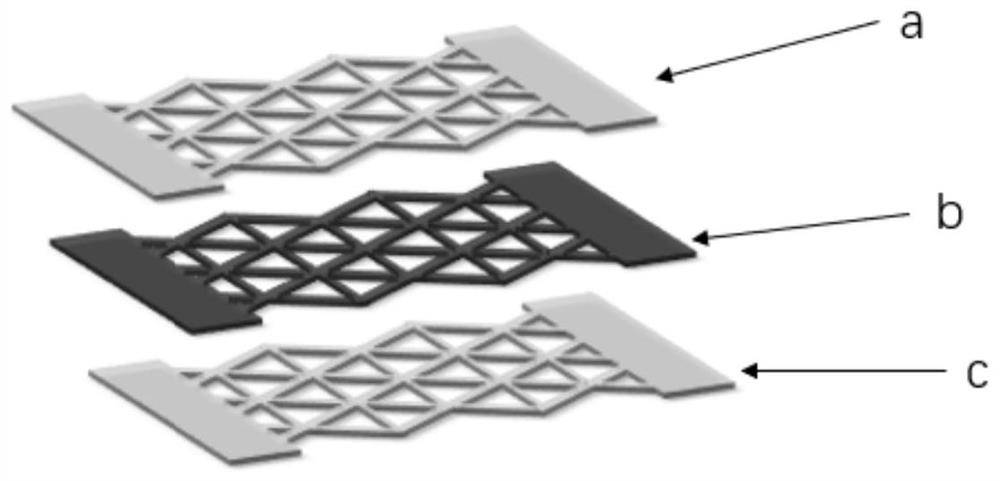

[0043] like figure 2 As shown, the low temperature stretchable flexible sensor provided by the present invention is composed of three layers, which are the base layer c obtained by 3D printing, the condu...

Embodiment 1

[0045] Step 1: Put 50mg of CNTs (carbon nanotubes) and 70mg of nanoscale Ag powder into a grinding bowl for thorough grinding. Then the ground powder is transferred to a beaker filled with 20ml ethanol solution, and the solution is sealed and preserved to prevent ethanol from volatilizing. Put it in an ultrasonic machine for ultrasonication for 1 hour, then place the mixed solution on a magnetic stirrer and stir for more than 10 hours until the mixture is evenly stirred and the mixed solution becomes viscous, and the composite conductive substance of the sensor is obtained.

[0046] Step 2: Weigh 2g Dragon Skin 10Cure Part A and 2g Dragon Skin 10Cure Part B and mix them in a 10ml beaker. This kind of silicone has good tensile properties and a wide temperature range, and can still be used normally in sub-zero low temperature environments. Then add 0.5ml of curing agent and 0.5ml of curing retarder to it, and keep stirring to make it fully mixed. The curing agent can make the m...

Embodiment 2

[0050] Step 1: Put 50mg of CNTs and 67.5mg of nanoscale Ag powder into a grinding bowl for thorough grinding. Then transfer the ground powder to a beaker containing 20ml of ethanol solution. Put it in an ultrasonic machine for ultrasonication for 1 hour, then place the mixed solution on a magnetic stirrer and stir for more than 10 hours until the mixture is evenly stirred and the mixed solution becomes viscous, and the composite conductive substance of the sensor is obtained.

[0051] Step 2: Weigh 2g Dragon Skin 10Cure Part A and 2g Dragon Skin 10Cure Part B and mix them in a 10ml beaker, then add 0.5ml curing agent and 0.5ml curing retarder to it, and keep stirring to make it fully mixed. Transfer the stirred colloid to the needle tube of the three-axis linkage dispensing machine, and fix it on the track movement end of the dispensing machine, add a pressure of 35PSI, and use the pre-designed dispensing machine program to print the mixed colloid on the The stencil is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com