3D printed solid-state battery and preparation method and application thereof

A 3D printing, solid-state battery technology, used in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of material rupture, electrical performance, battery diving, recession, etc., to improve lithium ion transmission, reduce raw material waste, and prepare simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

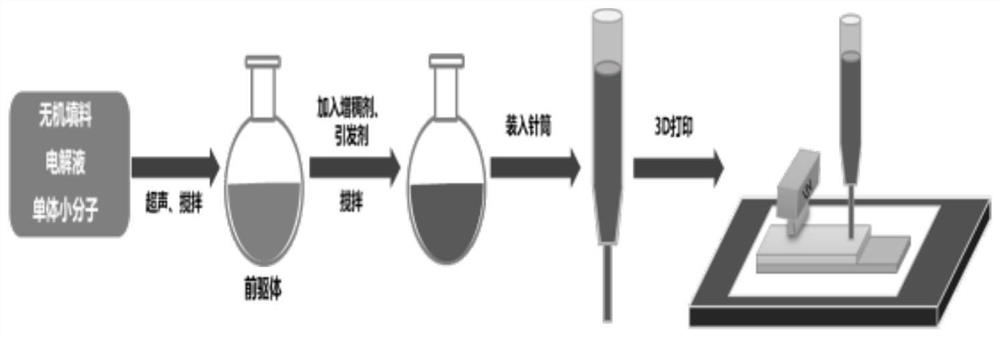

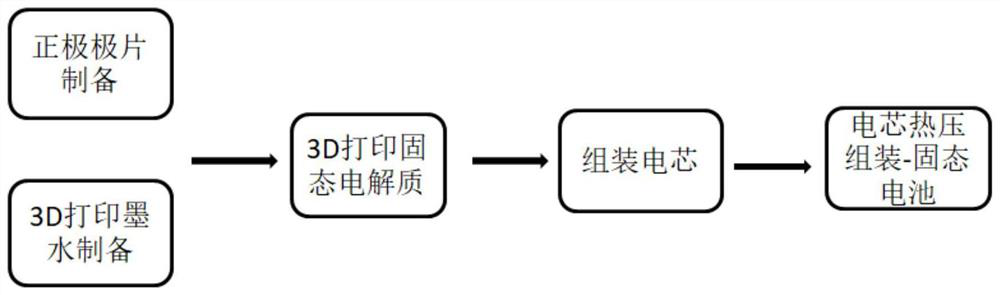

Method used

Image

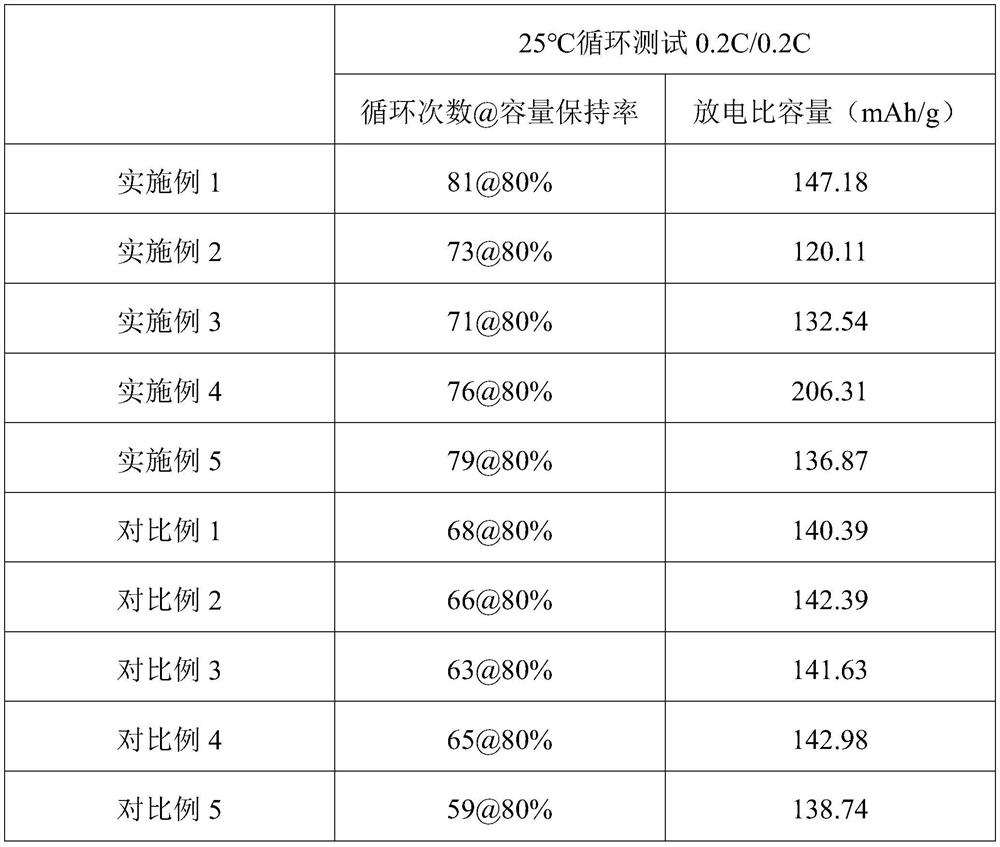

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing a 3D printed solid-state battery:

[0049] (1) Preparation of the positive pole piece: 3.5wt% of the binder polyvinylidene fluoride, 5% of polyethylene oxide and the positive solvent N-methylpyrrolidone were evenly mixed to prepare a glue solution, the rotation speed was 1000rpm, and the mixture was stirred for 7.5min. Positive electrode active material lithium iron phosphate 75wt%, electronic conductive agent conductive carbon black 7.5wt%, ion conductive agent succinonitrile 6%, lithium salt LiTFSI 3%, mix and stir with the above glue and positive electrode solvent evenly, rotate at 1000rpm, stir for 7.5min , the positive electrode slurry with a solid content of 35% can be obtained. Then, the positive electrode slurry was evenly coated on both sides of the aluminum foil of the positive electrode current collector, with a thickness of 150 μm, and the required positive electrode sheet was obtained through steps such as dry...

Embodiment 2

[0055] This embodiment provides a method for preparing a 3D printed solid-state battery:

[0056] (1) Preparation of the positive pole piece: 2 wt% of the binder polyvinylidene fluoride, 4% of polyethylene oxide and the positive solvent N-methylpyrrolidone were evenly mixed to prepare a glue solution, the rotation speed was 800 rpm, and the mixture was stirred for 10 min. Mix 70wt% of lithium manganate as the positive active material, 10wt% of conductive graphite as an electronic conductive agent, 10% of succinonitrile as an ion conductive agent, and 4% of lithium salt LiTFSI with the above glue and positive electrode solvent, mix and stir evenly at 800rpm, and stir for 10min. A positive electrode slurry with a solid content of 20% was obtained. Then, the positive electrode slurry was evenly coated on both sides of the aluminum foil of the positive electrode current collector, with a thickness of 100 μm, and the required positive electrode sheet was obtained through steps such...

Embodiment 3

[0062] This embodiment provides a method for preparing a 3D printed solid-state battery:

[0063] (1) Preparation of the positive pole piece: 5 wt% of the binder polyvinylidene fluoride, 6% of polyethylene oxide and the positive solvent N-methylpyrrolidone were evenly mixed to prepare a glue solution, the rotation speed was 1200 rpm, and the mixture was stirred for 5 min. The positive electrode active material lithium cobaltate 73wt%, the electronic conductive agent carbon fiber 10wt%, the ion conductive agent succinonitrile 2%, the lithium salt LiTFSI 4%, mix and stir with the above-mentioned glue and positive electrode solvent evenly, the rotation speed is 1200rpm, stir for 5min, you can get A positive electrode slurry with a solid content of 50%. Then, the slurry was evenly coated on both sides of the positive electrode current collector aluminum foil, with a thickness of 200 μm, and the required positive electrode sheet was obtained through steps such as drying, rolling, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com