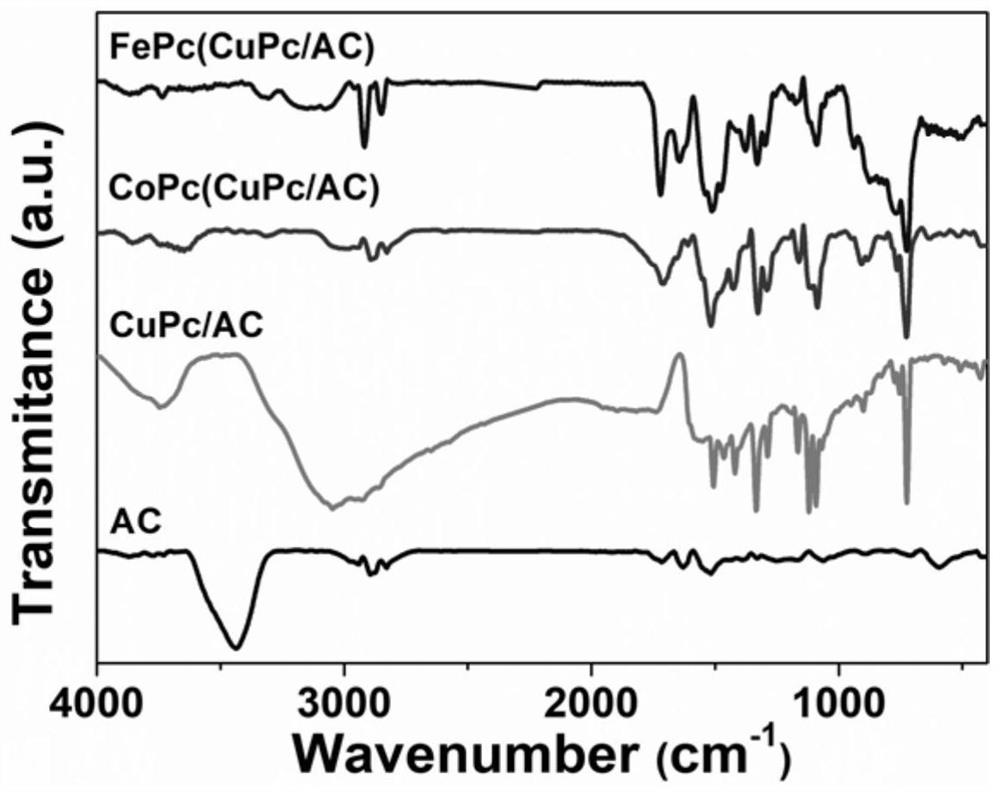

Transition metal phthalocyanine coated phthalocyanine blue/pitch coke activated carbon composite material lithium-thionyl chloride battery positive electrode catalyst and preparation method thereof

A technology for coating phthalocyanine blue and thionyl chloride batteries with phthalocyanine, which can be applied to battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

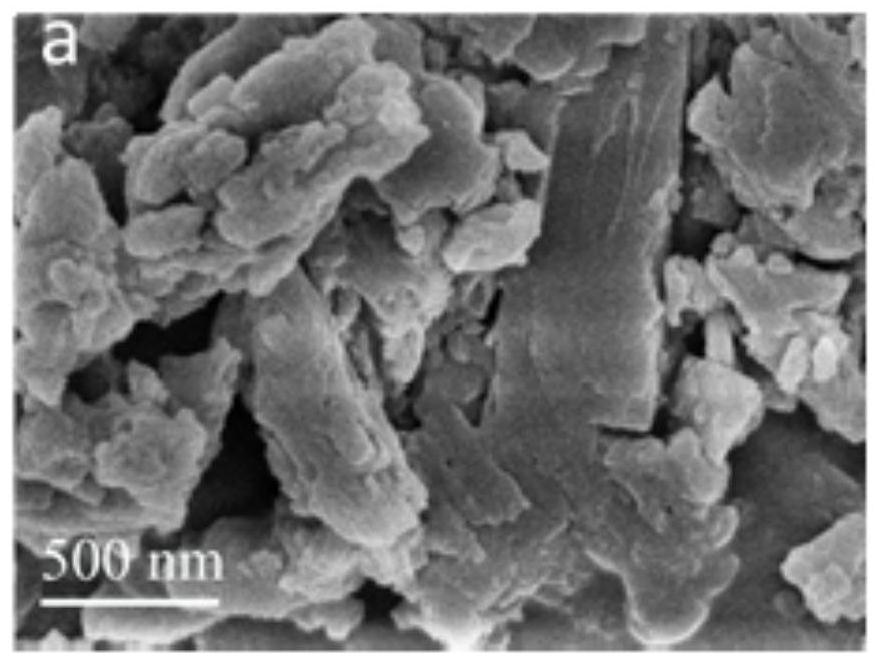

[0033] Taking the synthesis of CoPc (CuPc / AC) as an example, the following steps are included:

[0034] Step 1: Take 0.41g of phthalic anhydride and 0.05g of specific surface area of 1400m 2 g -1 The pitch coke activated carbon is ground evenly in an agate mortar;

[0035] Step 2: Take 0.60g of urea, 0.06g of ammonium molybdate, and 0.25g of copper chloride dihydrate, add them to the agate mortar in step 1, grind them evenly, and transfer them to the corundum porcelain boat;

[0036] Step 3: Transfer the corundum porcelain boat from step 2 into the muffle furnace, -1 The heating rate is increased from room temperature to 140°C and kept for 1.0h; then at 10°C·min -1 The heating rate was increased to 270°C, kept for 2 hours, and then naturally cooled to room temperature to obtain the initial product;

[0037] Step 4: Rinse the initial product of step 3 with deionized water for 10 hours, pour off the impurities in the upper layer, repeat 5 times, and then filter with ethano...

Embodiment 2

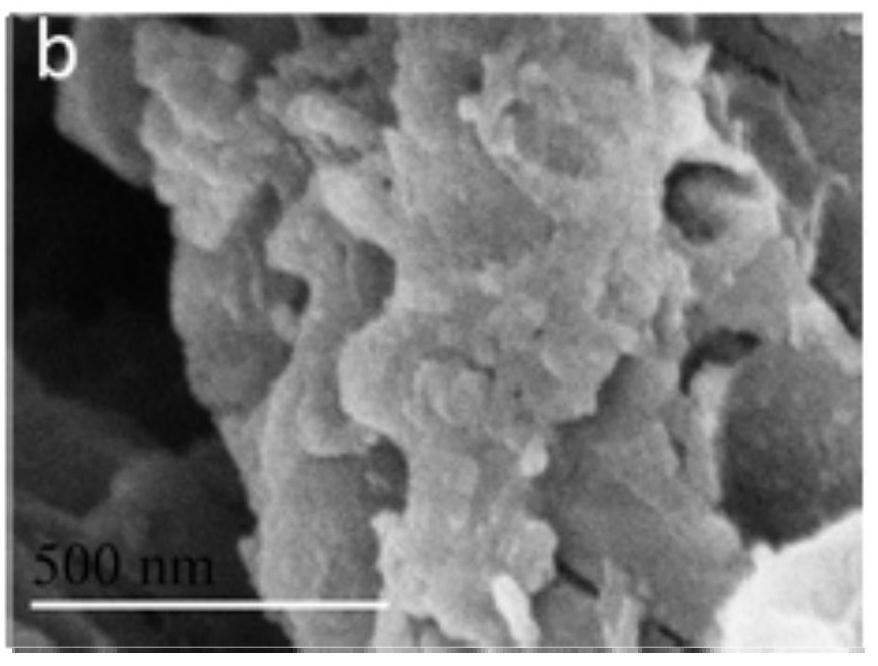

[0042] Taking the synthesis of CoPc (CuPc / AC) as an example, the following steps are included:

[0043] Step 1: Take 1.60g of phthalic anhydride and 0.20g of specific surface area of 2400m 2 g -1 The pitch coke activated carbon is ground evenly in an agate mortar;

[0044] Step 2: Take 2.20g of urea, 0.05g of ammonium molybdate, and 1.00g of copper chloride dihydrate, add them to the agate mortar in step 1, grind them evenly, and transfer them to the corundum porcelain boat;

[0045] Step 3: Transfer the corundum porcelain boat from step 2 into the muffle furnace, -1 The heating rate is increased from room temperature to 130°C and kept for 1.5h; then at 10°C·min -1 The heating rate was increased to 250°C, kept for 2 hours, and then naturally cooled to room temperature to obtain the initial product;

[0046] Step 4: Rinse the initial product of step 3 with deionized water for 24 hours, pour off the impurities in the upper layer, repeat 3 times, and then filter with ethano...

Embodiment 3

[0051] Taking the synthesis of CoPc (CuPc / AC) as an example, the following steps are included:

[0052] Step 1: Take 0.82g of phthalic anhydride and 0.10g of specific surface area of 2000m 2 g -1 The pitch coke activated carbon is ground evenly in an agate mortar;

[0053] Step 2: Take 1.20g of urea, 0.24g of ammonium molybdate, and 0.42g of copper chloride dihydrate, add them to the agate mortar in step 1, grind them evenly, and transfer them to the corundum porcelain boat;

[0054] Step 3: Transfer the corundum porcelain boat from step 2 into the muffle furnace, -1 The heating rate is increased from room temperature to 100°C and kept for 1.0h; then at 8°C·min -1 The heating rate was raised to 200°C, kept for 1.5h, and then naturally cooled to room temperature to obtain the initial product;

[0055] Step 4: Rinse the initial product of step 3 with deionized water for 10 hours, pour off the impurities in the upper layer, repeat 5 times, and then filter with ethanol 3 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com