Heat-sealable antistatic polyamide co-extruded composite film as well as preparation method and application thereof

A co-extrusion composite and polyamide technology, which is applied in the field of heat-sealable antistatic polyamide co-extrusion composite film and its preparation, can solve the problems of uneven flow of the heat-sealing layer, easy generation of static slippery agent, and impact on performance. Achieve the effects of reducing heat shrinkage, excellent antistatic performance, and enhancing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

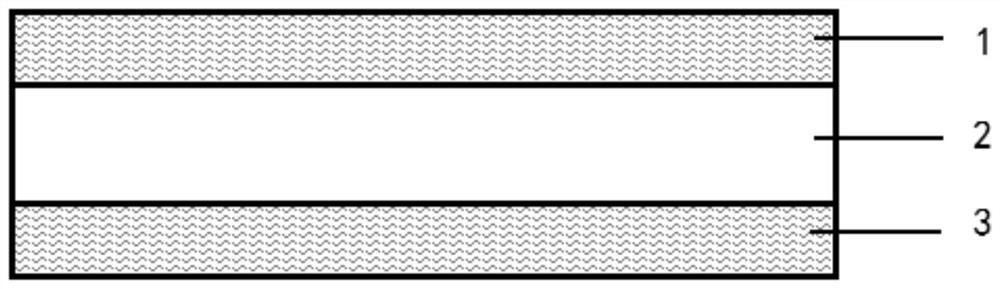

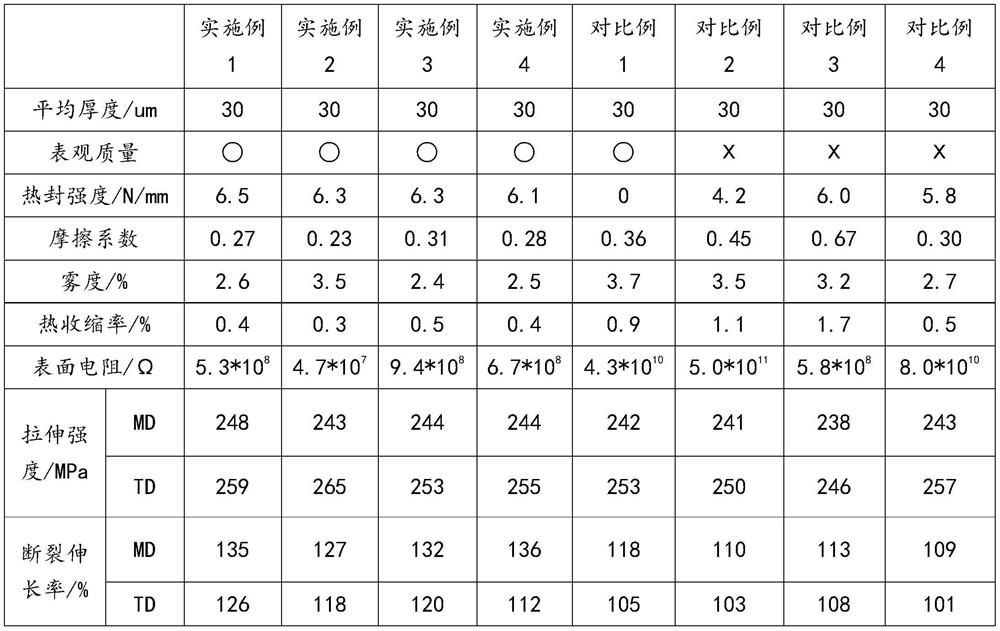

[0042] The heat-sealable polyamide co-extrusion film has a three-layer structure, and the structure of the film is a heat-sealable polyamide surface layer, a polyamide core layer, and a polyamide functional surface layer from the outside to the inside;

[0043] The mass percent of each component of the heat-sealable polyamide surface layer is: 99.6% of nylon 6 / 66 / 1010 copolymer, 0.1% of polytetrafluoroethylene (PTFE) micropowder, and 0.3% of organosilicon crosslinking microspheres.

[0044] The mass percent of each component of the polyamide core layer is: 82% of nylon 6, 15% of PA6-b-PEG, and 3% of active nano magnesium oxide.

[0045] The mass percent of each component of the polyamide functional surface layer is: 84.7% of nylon 6, 15% of PA6-b-PEG, and 0.3% of organic silicon cross-linked microspheres.

[0046] Its preparation method:

[0047] B1. Mix the components in the heat-sealable polyamide surface layer, polyamide core layer and polyamide functional surface layer in t...

Embodiment 2

[0052] The heat-sealable polyamide co-extrusion film has a three-layer structure, and the structure of the film is a heat-sealable polyamide surface layer, a polyamide core layer, and a polyamide functional surface layer from the outside to the inside;

[0053] The mass percent of each component of the heat-sealable polyamide surface layer is: 98.5% of nylon 6 / 66 / 1010 copolymer, 0.5% of polytetrafluoroethylene (PTFE) micropowder, and 1% of organosilicon crosslinking microspheres.

[0054] The mass percent of each component of the polyamide core layer is: 75% of nylon 6, 20% of PA6-b-PEG, and 5% of active nano magnesium oxide.

[0055] The mass percent of each component of the polyamide functional surface layer is: 79% of nylon 6, 20% of PA6-b-PEG, and 1% of organic silicon cross-linked microspheres.

[0056] Its preparation method is identical with embodiment 1.

Embodiment 3

[0058] The heat-sealable polyamide co-extrusion film has a three-layer structure, and the structure of the film is a heat-sealable polyamide surface layer, a polyamide core layer, and a polyamide functional surface layer from the outside to the inside;

[0059] The mass percent of each component of the heat-sealable polyamide surface layer is: 99.85% of nylon 6 / 66 / 1010 copolymer, 0.05% of polytetrafluoroethylene (PTFE) micropowder, and 0.1% of organosilicon crosslinking microspheres.

[0060] The mass percent of each component of the polyamide core layer is: 89% of nylon 6, 10% of PA6-b-PEG, and 1% of active nano magnesium oxide.

[0061] The mass percent of each component of the polyamide functional surface layer is: 89.9% of nylon 6, 10% of PA6-b-PEG, and 0.1% of organic silicon cross-linked microspheres.

[0062] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com