Hydrogen storage cylinder for explosion-proof hydrogen fuel cell automobile and manufacturing method thereof

A technology of a fuel cell and a manufacturing method, which is applied in the field of high-pressure gaseous hydrogen storage, can solve the problems of hydrogen embrittlement safety hazards and cracking of aluminum inner liner, and achieve the effects of avoiding safety hazards and increasing interlayer shear force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

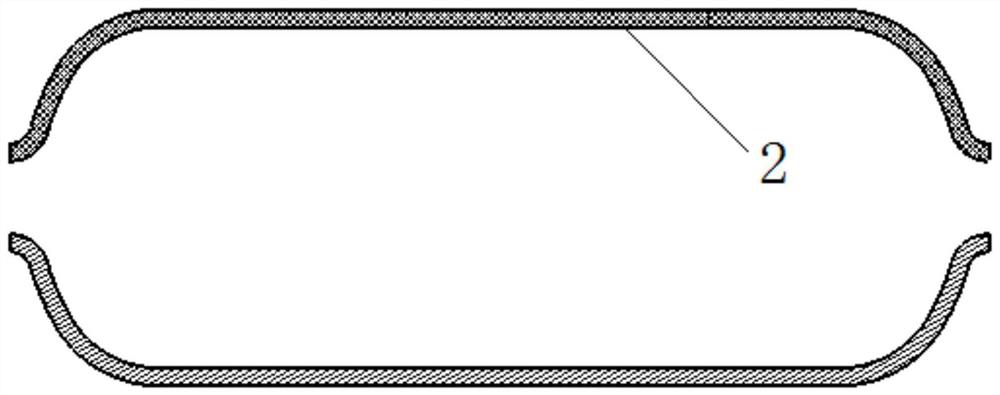

Image

Examples

Embodiment 1

[0055] A method for manufacturing a hydrogen storage cylinder for an explosion-proof hydrogen fuel cell vehicle of the present invention comprises the following steps,

[0056] Step 1, the preparation of surfactant coupling agent;

[0057] Mix the silane coupling agent and epoxy resin high-performance toughening modifier RF-400 at room temperature according to the mass ratio of 2:2.5, stir evenly and place it for 10 minutes;

[0058] The silane coupling agent is vinyltriethoxysilane.

[0059] Step 2, preparation of low temperature curing epoxy resin;

[0060] Mix epoxy resin and E300 curing agent at room temperature according to the mass ratio of 9:2.5, stir evenly and place for 5 minutes;

[0061] Step 3, preparation of medium temperature curing epoxy resin;

[0062] Epoxy resin and dipropylene glycol methyl ether (DPM) as curing agent are mixed at room temperature according to the ratio of 9:2.5 in mass ratio, stirred evenly and placed for 5 minutes;

[0063] Step 4, the...

Embodiment 2

[0076] A method for manufacturing a hydrogen storage cylinder for an explosion-proof hydrogen fuel cell vehicle of the present invention comprises the following steps,

[0077] Step 1, the preparation of surfactant coupling agent;

[0078] Mix the silane coupling agent and epoxy resin high-performance toughening modifier RF-400 at room temperature according to the mass ratio of 4:5, stir well and let stand for 11 minutes;

[0079] The silane coupling agent is vinyltrimethoxysilane.

[0080] Step 2, preparation of low temperature curing epoxy resin;

[0081] Mix epoxy resin and E300 curing agent at room temperature according to the mass ratio of 9.5:2.7, stir evenly and let stand for 7 minutes;

[0082] Step 3, preparation of medium temperature curing epoxy resin;

[0083] Epoxy resin and dipropylene glycol methyl ether (DPM) as curing agent are mixed at room temperature according to the ratio of 9.5:2.7 in mass ratio, and placed for 7 minutes after stirring;

[0084] Step ...

Embodiment 3

[0097] A method for manufacturing a hydrogen storage cylinder for an explosion-proof hydrogen fuel cell vehicle of the present invention comprises the following steps,

[0098] Step 1, the preparation of surfactant coupling agent;

[0099] Mix the silane coupling agent and epoxy resin high-performance toughening modifier RF-400 at room temperature according to the mass ratio of 5:7, stir well and let stand for 12 minutes;

[0100] The silane coupling agent is vinyltris(β-methoxyethoxy)silane.

[0101] Step 2, preparation of low temperature curing epoxy resin;

[0102] Mix epoxy resin and E300 curing agent at room temperature according to the mass ratio of 10:3, stir evenly and let stand for 8 minutes;

[0103] Step 3, preparation of medium temperature curing epoxy resin;

[0104] Epoxy resin and dipropylene glycol methyl ether (DPM) as a curing agent are mixed at room temperature according to a mass ratio of 10:3, stirred evenly and placed for 8 minutes;

[0105] Step 4, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com