Hydrogel capable of being used for marine antifouling and preparation method thereof

A marine antifouling and hydrogel technology, applied in gel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of poor mechanical properties of hydrogels, achieve excellent anti-swelling properties, improve mechanical properties, and enhance Effect of anti-swelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

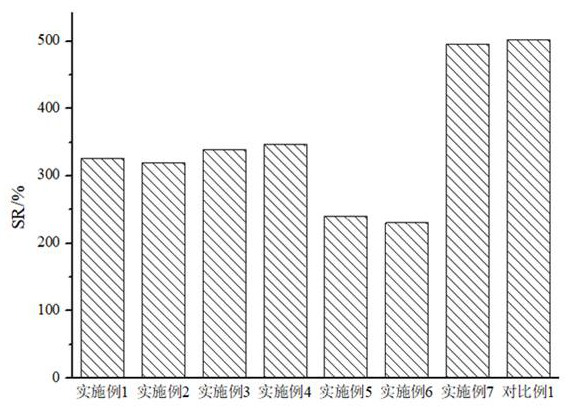

Image

Examples

Embodiment 1

[0026] A method for preparing marine anti-pollution gel, comprising the following steps: first, polyvinyl alcohol is added to deionized water, heated at 90°C to a colorless and transparent solution; after cooling to room temperature, acrylamide is added, and water is added to stir until completely dissolved; add picoxystrobin and Tween 80, and continue to stir for 12 minutes; transfer to an ultrasonic pulverizer and ultrasonically emulsify for 30 minutes under the condition of 250w, until the solution becomes a homogeneous emulsion, add N,N'-methylenebispropylene Amide, initiator ammonium persulfate; finally, pour the solution into a flake glass mold and react at a constant temperature of 65°C for 7 hours until gelling.

[0027] In the above steps, the mass volume ratio of polyvinyl alcohol to deionized water is 1g:10mL; the mass ratio of acrylamide to polyvinyl alcohol is 3:1; the mass ratio of picoxystrobin to polyvinyl alcohol is 0.5:1; The mass ratio of N,N'-methylenebisac...

Embodiment 2

[0029] A kind of hydrogel preparation method that can be used for marine antifouling differs from Example 1:

[0030] During the hydrogel preparation process: the mass ratio of acrylamide to polyvinyl alcohol is 3.2:1; the mass ratio of picoxystrobin to polyvinyl alcohol is 0.55:1; The mass ratio of ammonium sulfate to polyvinyl alcohol is 0.38:6:100; the mass ratio of Tween 80 to polyvinyl alcohol is 0.0055:1.

Embodiment 3

[0032] A kind of hydrogel preparation method that can be used for marine antifouling differs from Example 1:

[0033] During the hydrogel preparation process: the mass ratio of acrylamide to polyvinyl alcohol was 3.5:1; the mass ratio of picoxystrobin to polyvinyl alcohol was 0.6:1; The mass ratio of ammonium sulfate to polyvinyl alcohol is 0.4:7:100; the mass ratio of Tween 80 to polyvinyl alcohol is 0.006:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com