Pre-paved macromolecular waterproof roll main body material as well as preparation method and application thereof

A technology of polymer waterproofing and main material, which is applied in building thermal insulation materials, chemical instruments and methods, layered products, etc. Improve heat resistance and environmental stress crack resistance, and ensure the effect of lap quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

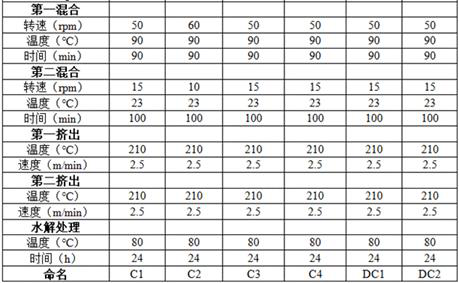

[0063] This example is used to illustrate that the main material of the pre-laid polymer waterproof membrane according to the present invention adopts the formula in Table 1, and the main material of the pre-laid polymer waterproof membrane is prepared according to the following method.

[0064] The preparation method of the pre-laid polymer waterproof membrane main body material comprises the following steps:

[0065] (1) Mix the components in component A for the first time to obtain mixture I; the component A contains HDPE resin, LLDPE resin, POE resin II and color masterbatch;

[0066] The first mixing condition is: stirring at a speed of 50 rpm for 90 minutes at 90°C;

[0067] The components in the component B are mixed for the second time to obtain a mixture II; the component B contains a vinylsilane crosslinking agent, an organotin catalyst, and an initiator;

[0068] The second mixing condition is: stirring at 15 rpm for 100 min at 23°C;

[0069] (2) Extruding the mix...

Embodiment 2

[0074] This embodiment adopts the same flow process as embodiment 1 to carry out, and the difference is that in this embodiment:

[0075] The formulations and process parameters of the main materials of the pre-laid polymer waterproof membrane are different, see Table 1 for details.

[0076] The main material C2 of the pre-laid polymer waterproof membrane was prepared.

Embodiment 3

[0078] This example adopts the formula and method similar to Example 1 to prepare the main material of the pre-laid polymer waterproof membrane, the difference is: the weight of the crosslinking agent I is replaced by the crosslinking agent III, and the rest are the same as in Example 1. The main material C3 of the pre-laid polymer waterproof membrane was prepared, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com