Production method of high-quality AlV55 alloy

A production method and high-quality technology, applied in the field of metallurgy, can solve the problems of high oxide film fine powder, low impurity content and high yield of AlV55 alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

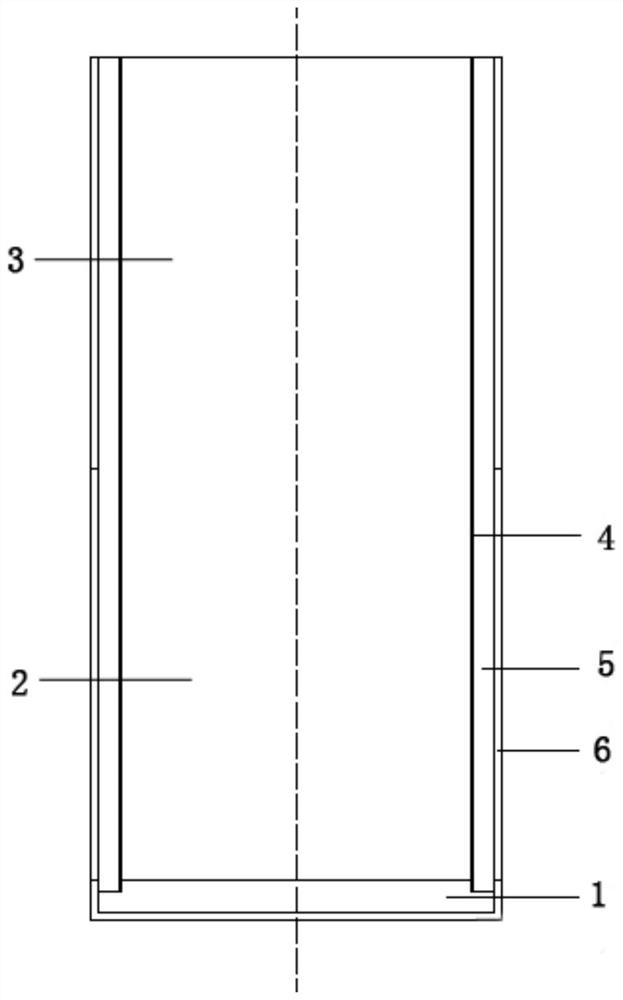

Image

Examples

Embodiment 1

[0058] High purity V 2 o 5 (purity 99.5%, wherein Fe is 0.007%, Si is 0.008%, C is 0.008%, particle size 1 ~ 2mm) 100kg, high-purity metal Al (purity 99.7%, wherein Fe is 0.004%, Si is 0.005%, C is 0.005%, particle size 1~2mm) 90kg and high-purity CaO (purity 98.6%, wherein Fe is 0.18%, Si is 0.15%, C is 0.25%, particle size 120~160 orders) 12kg is mixed in the feeding tank of packing. Load the uniformly mixed materials into the reaction furnace three times, and compress and exhaust each time after loading the materials. A 4:1 mixture of barium peroxide and aluminum powder was used as the igniter to initiate the thermite reaction. After the reaction is stable, push the furnace body into the vacuum chamber, vacuumize to 15Pa, fill with argon to 93kPa, cool for 36 hours, dismantle the furnace to obtain Fe content of 0.16%, Si content of 0.17%, C content of 0.012%, O content of 0.05%, N The high-quality AlV55 alloy with a content of 0.014% has an alloy yield of 81.8%.

Embodiment 2

[0060] High purity V 2 o 5 (purity 99.6%, wherein Fe is 0.006%, Si is 0.007%, C is 0.006%, particle size<1mm) 120kg, high-purity metal Al (purity 99.8%, wherein Fe is 0.003%, Si is 0.004%, C is 0.004 %, particle size 0.5~1mm) 106.8kg and high-purity CaO (purity 98.5%, wherein Fe is 0.19%, Si is 0.17%, C is 0.27%, particle size 160~200 orders) 18kg is mixed in the feeding tank of packing. The uniformly mixed materials are loaded into the reaction furnace in 4 times, and each time the materials are loaded, they are compressed and exhausted. A 4:1 mixture of barium peroxide and aluminum powder was used as the igniter to initiate the thermite reaction. After the reaction is stable, push the furnace body into the vacuum chamber, vacuumize to 30Pa, fill with argon to 94kPa, cool for 38 hours and dismantle the furnace to obtain Fe content of 0.17%, Si content of 0.15%, C content of 0.013%, O content of 0.055%, N The high-quality AlV55 alloy with a content of 0.013% has an alloy yi...

Embodiment 3

[0062] High purity V 2 o 5 (purity 99.7%, wherein Fe is 0.005%, Si is 0.006%, C is 0.007%, particle size 2 ~ 3mm) 150kg, high-purity metal Al (purity 99.7%, wherein Fe is 0.004%, Si is 0.005%, C is 0.004%, particle size 2~3mm) 132kg and high-purity CaO (purity 98.5%, wherein Fe is 0.019%, Si is 0.016%, C is 0.28%, particle size 120~160 orders) 24kg is mixed in the charging tank of packing. Load the uniformly mixed materials into the reaction furnace five times, and compress and exhaust each time after loading the materials. After the reaction is stable, push the furnace body into the vacuum chamber, vacuumize to 35Pa, fill with argon to 96kPa, cool for 40 hours and dismantle the furnace to obtain Fe content of 0.16%, Si content of 0.15%, C content of 0.014%, O content of 0.052%, N The high-quality AlV55 alloy with a content of 0.012% has an alloy yield of 82.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com