High-strength waterproof anti-cracking putty powder and preparation method thereof

An anti-cracking putty, high-strength technology, applied in the direction of filling slurry, etc., can solve the problems of non-waterproof, poor film quality, low strength, etc., to achieve good water resistance, dense film layer, and prevent the penetration of water molecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

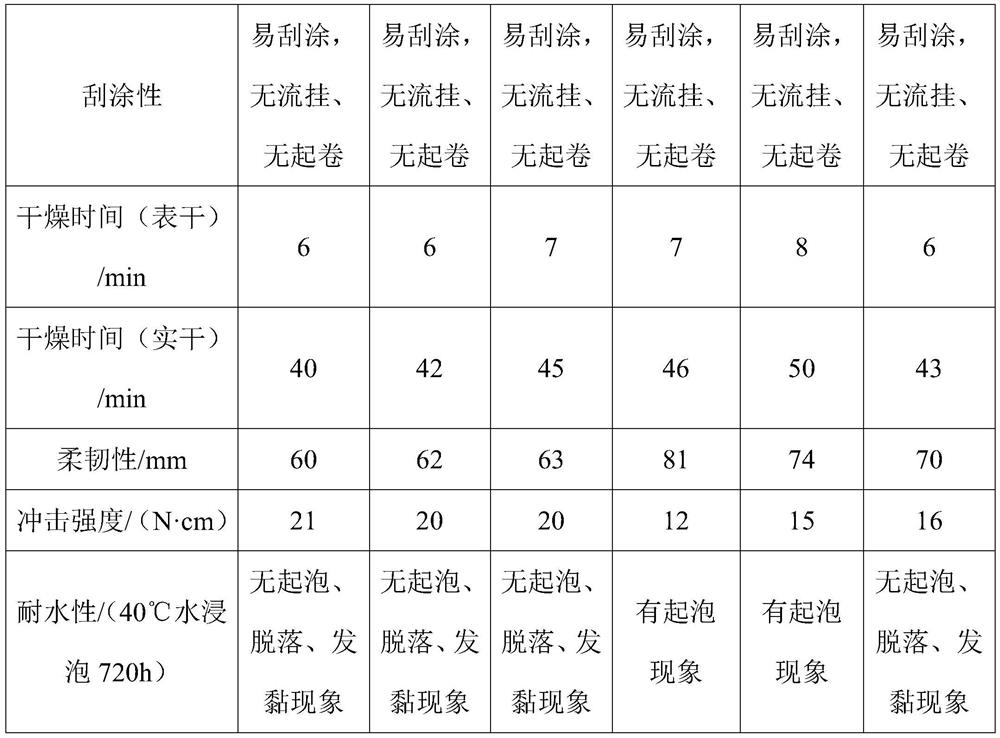

Examples

Embodiment 1

[0027] A high-strength water-resistant and crack-resistant putty powder, including the first component, the second component, and the third component with a mass ratio of 50:1:5;

[0028] The first component includes the following components:

[0029] 45 parts of unsaturated polyester resin, 3 parts of cobalt naphthenate, 5 parts of hydroxylated multi-walled carbon nanotubes, 1 part of hydroxypropyl methylcellulose ether, 40 parts of filler, 0.5 parts of thixotropic lubricant RMA-1;

[0030] The second component is cyclohexanone peroxide curing agent, and the third component is butyl formate diluent.

[0031] The preparation method of unsaturated polyester resin is as follows:

[0032] Mix maleic anhydride, phthalic anhydride, fumapimaric acid and 1,2-propylene glycol with a mass ratio of 35:55:15:75, heat up to melting under the protection of an inert gas, start stirring, and heat up to React at 165°C for 30 minutes, add stannous octoate and continue to heat up to reflux, r...

Embodiment 2

[0037] A high-strength water-resistant and crack-resistant putty powder, including the first component, the second component, and the third component with a mass ratio of 50:1:3;

[0038] The first component includes the following components:

[0039] 50 parts of unsaturated polyester resin, 5 parts of cobalt naphthenate, 6 parts of hydroxylated multi-walled carbon nanotubes, 1 part of hydroxypropyl methylcellulose ether, 50 parts of filler, 1 part of thixotropic lubricant RMA-1;

[0040] The second component is cyclohexanone peroxide curing agent, and the third component is butyl formate diluent.

[0041] The preparation method of unsaturated polyester resin is as follows:

[0042] Mix maleic anhydride, phthalic anhydride, fumapimaric acid and 1,2-propylene glycol with a mass ratio of 35:55:15:75, heat up to melting under the protection of an inert gas, start stirring, and heat up to React at 170°C for 50 minutes, add stannous octoate and continue to heat up to reflux, remo...

Embodiment 3

[0047] A high-strength water-resistant and crack-resistant putty powder, including the first component, the second component, and the third component with a mass ratio of 40:1:3;

[0048] The first component includes the following components:

[0049] 40 parts of unsaturated polyester resin, 3 parts of cobalt naphthenate, 4 parts of hydroxylated multi-walled carbon nanotubes, 0.5 part of hydroxypropyl methylcellulose ether, 40 parts of filler, 0.5 part of thixotropic lubricant RMA-1;

[0050] The second component is cyclohexanone peroxide curing agent, and the third component is butyl formate diluent.

[0051] The preparation method of unsaturated polyester resin is as follows:

[0052]Mix maleic anhydride, phthalic anhydride, fumapimaric acid and 1,2-propanediol with a mass ratio of 30:50:10:70, heat up to melting under the protection of an inert gas, start stirring, and heat up to React at 160°C for 30 minutes, add stannous octoate and continue to heat up to reflux, distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com