Manufacturing method of injection-molded high-frequency copper clad laminate

A manufacturing method and technology for copper clad laminates, which are used in household components, applications, household appliances, etc., can solve the problems of insufficient dielectric loss, uneven material mixing, easy falling off, etc., so as to reduce dielectric loss, improve bonding effect, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

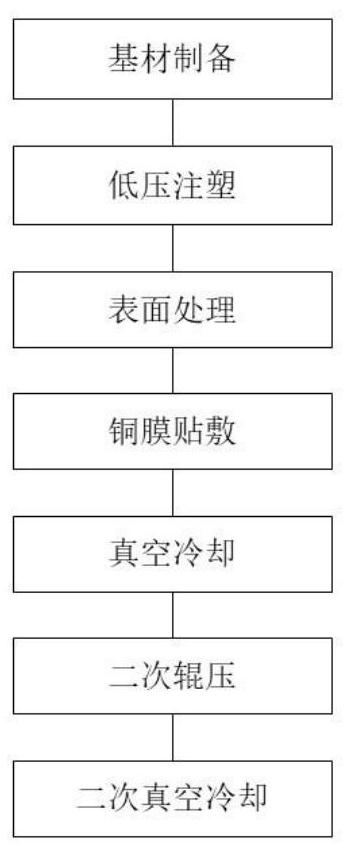

[0044] The manufacturing method of injection molding high frequency copper clad laminate includes:

[0045] Step 1, substrate preparation

[0046] The base materials will be prepared according to the quality: 300 parts of phenolic resin, 200 parts of epoxy resin, 200 parts of polyethylene, 5 parts of magnesium hydroxide, 200 parts of cyclodextrin, 150 parts of nano-alumina powder and 150 parts of silicon dioxide;

[0047] Mix the prepared base materials, put them into a ball mill for ball milling after mixing, and ensure that the ball milling temperature does not exceed 50°C during the ball milling process;

[0048] Ball mill until the particle size of the base material is less than 0.05mm, put the base material into a heating container for heating, heat to 300°C to make the base material flow as a whole, then cool down and extrude to make base material particles;

[0049] Step 2. Low pressure injection molding

[0050] Add epoxy resin curing agent to the substrate particles...

Embodiment 2

[0073] Step 1, substrate preparation

[0074] The base materials will be prepared according to the quality: 200 parts of phenolic resin, 100 parts of epoxy resin, 100 parts of polyethylene, 1 part of magnesium hydroxide, 100 parts of cyclodextrin, 100 parts of nano-alumina powder and 100 parts of silicon dioxide;

[0075] Mix the prepared base materials, put them into a ball mill for ball milling after mixing, and ensure that the ball milling temperature does not exceed 50°C during the ball milling process;

[0076] Ball mill until the particle size of the base material is less than 0.05mm, put the base material into a heating container for heating, heat to 300°C to make the base material flow as a whole, then cool down and extrude to make base material particles;

[0077] Step 2. Low pressure injection molding

[0078] Add epoxy resin curing agent to the substrate particles obtained in step 1, mix and heat, heat to 250°C and inject into a low-pressure injection mold, and kee...

Embodiment 3

[0086] Step 1 also includes an ultrasonic oscillation mixing step, specifically:

[0087] Ultrasonic mixing is performed on the ball-milled base material before heating, that is, the ball-milled base material is placed on an ultrasonic oscillator for ultrasonic mixing, the oscillation time is 10-15min, and the oscillation frequency is 150kHz-300kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com